EXACT Experiment and Analysis of Aluminum Cup Drawing Test

The ESFORM Benchmark promotes the constitution of a network to deeply analyze a challenge present in the community of material forming processes.

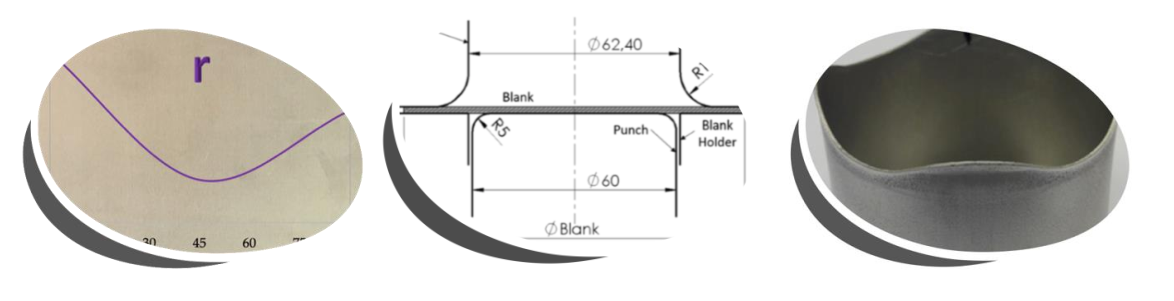

The earing predictions formed during the cup drawing process is an old problem (Fig.1). However here, for the first time, the organizers (see Table 1), eight well-known scientists of the ESAFORM community decide to investigate together with all the benchmark participants (Table 2) their practice in both experimental and numerical fields. The discussions and results of this work will be presented at the ESAFORM 2021 conference and gathered later within an article in the International Journal of Material Forming. The participants and the organizers together will point the impact of different choices on the results.

Fig.1 Technical challenge: earing prediction for an anisotropic material

Fig.1 Technical challenge: earing prediction for an anisotropic material

Most sheet forming benchmarks include information such as:

-

the hardening law parameters, based on limited experimental data (generally, r-values, yield stresses and ultimate strengths for 3 loading directions) extracted from uniaxial tension tests

-

the coefficients for certain yield functions, available in the material libraries of most commercial software.

The features of the ESAFORM 2021 Benchmark are :

-

identification of constitutive models performed by participants;

-

information concerning the experimental scatter, the “raw” data, where 3 laboratories have collaborated to duplicate some types of tests;

-

different loading paths, tensile tests, monotonic and reverse simple shear tests, biaxial tension tests;

-

analysis of the anisotropy induced by the deformation process based on the data of the evolution of initial texture until post-test texture;

-

multi-scale work thanks to EBSD measurements as well as classical mechanical test results

The EXACT benchmark offers the opportunity to:

-

analyze, understand and communicate about the performance of simulation approaches at different scales based on available experimental data

-

exchange between numerical teams and experimental ones about the issues that can happen in each characterization method and the procedure used to treat the raw data

Benchmark results are not presented here, but they will be published before ESAFORM 2022 in International Journal of Material Forming. Knowing the results gathered, time is required after the conference to allow a fruitful discussion between all the contributors to the benchmark. They will prepare all together an article pointing advantages and drawbacks of different identification strategies for the constitutive models as well as of the different simulations approaches. The goal is actually to share the skill of all the teams and individual participants as much as possible.

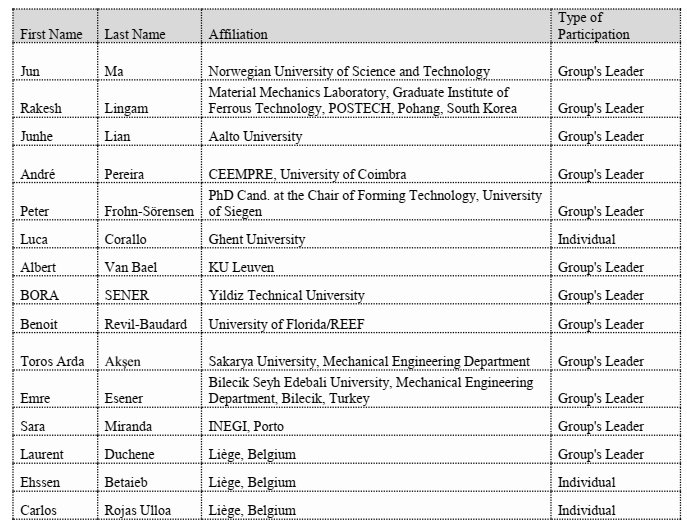

Table 1 The organizers of ESAFORM 2021 and their motivations

|

Frederic Barlat (Materials Mechanics Laboratory, GIFT- POSTECH, Republic of Korea) General interest in constitutive modeling and plastic anisotropy. Diffuse a correct understanding of aluminum sheet modelling. Contribute to ESAFORM scientific community. |

|

Oana Cazacu (Dept of Mechanical & Aerospace Engineering, University of Florida/REEF, USA) Interested in understanding how experimental error and hypotheses used in “raw data” interpretation propagate into parameter identification and consequently numerical predictions; aiming to provide understanding of the influence of the identification procedure and the type of data used as input on the numerical predictions with any given model. Contribute to ESAFORM being a “game changer” in data analysis and predictions of performance during forming. |

| Anne Marie Habraken (Materials and Solid Mechanics (MSM) University of Liège, Belgium) Interested to identify macroscopic model ability versus crystal plasticity for strong texture sheet material still industrial. To promote science and discussion not competition, friendship and exchange between ESAFORM community. |

|

Toshihiko Kuwabara (Division of Advanced Mechanical Systems Engineering, Institute of Engineering, Tokyo University of Agriculture and Technology, Japan) Compare characterization results and discuss with modelling teams. In charge of part of experimental raw data. |

|

Augusto Lopes (Dept of Materials and Ceramic Engineering, University of Aveiro, Portugal) Interest in the relationship between material structure and the macroscopic behavior of metals. In charge of the texture analyses. |

|

Marta Oliveira (CEMMPRE, Centre for Mechanical Engineering, Materials and Processes, Department of Mechanical Engineering, Faculty of Sciences and Technology, University of Coimbra, Portugal) Interested in understanding the impact of decisions made in the: (i) analysis of experimental data; (ii) selection of the constitutive models and experimental data sets (iii) identification procedures adopted for the hardening and yield criteria parameters; and (iv) modelling of the process conditions, on the numerical predictions performance. To share and gain knowledge with the ESAFORM scientific community. |

|

Abel Santos (Dept of Mechanical Engineering, University of Porto, Portugal) Interested in constitutive modeling and plastic anisotropy. In charge of the cylindrical cup forming experimental test and analysis. Contribute to promote the discussion, improve knowledge and validating numerical predictions based on reliable experimental results. |

|

Gabriela Vincze (Dept of Mechanical Engineering, University of Aveiro, Portugal) Interest in experimental techniques and material modeling. Interest in founding an active open friendly network in the area of sheet metal forming. Coordinate an international work diffusing good practice. |

This team has attracted their colleagues but also many other teams within the adventure. Table 2 provides the list of participants:

Table 2 The participants of ESAFORM 2021 Benchmark

For more details consults : EXACT (benchmarkexact.org)