Bioenergy value of seed waste from the Mexican date (Phoenix dactylifera L.) industry

Résumé

Valeur bioénergétique des déchets de grains provenant de l'industrie mexicaine des dattes (Phoenix dactylifera L.)

Description du sujet. Les déchets de grains de dattes (Phoenix dactylifera L.), provenant de l'industrie des dattes au Mexique, sont une source de biomasse intéressante étant donné leur contenu énergétique. En plus, ils représentent une ressource renouvelable et disponible qui n’est pas valorisée actuellement.

Objectifs. Dans le présent travail, la récupération d'énergie thermique des grains de dattes brutes (GDB) et des grains de dattes transformées (GDT) a été calculée. Et aussi, nous avons estimé la quantité de biocarburant qui pourrait potentiellement être utilisée.

Méthode. La composition physico-chimique et le comportement thermique du GDB et du GDT ont été déterminés pour évaluer leur utilité pour la production d'énergie thermique. Des analyses proximales et thermogravimétriques, une imagerie au microscope électronique à balayage et différentes propriétés du carburant telles que pouvoir calorifique supérieur (PCS), densité apparente et énergétique et indice de valeur du carburant (FVI) ont été déterminées. Ensuite, la production potentielle d'énergie à partir des déchets de grains de l'industrie mexicaine des dattes a été estimée.

Résultats. Le GDB a présenté un meilleur PCS de 19,33 MJ·kg-1 et une densité énergétique de 14,42 MJ·m-3 ; cependant, le GDT a une humidité plus faible de 5,12 % et une teneur en cendres de 5,89 %. Le FVI du GDT est plus favorable que le GDB, 363,81 et 208,43 respectivement.

Conclusions. La production d'énergie potentielle à partir des grains de dattes produites au Mexique en 2018 a été calculée en 10,17 TJ de GDB, 8,04 TJ de GDT et 2,01 TJ de biodiesel et avec une tendance à augmenter chaque année.

Abstract

Description of the subject. Date (Phoenix dactylifera L.) seed waste, from the date industry in Mexico, is an attractive source of biomass for bioenergy due to its renewability, availability, and not being otherwise usable.

Objectives. In this research project, we calculated and determined the amount of biofuel that could potentially be used from the thermal energy recovery of raw date seed (RDS) and processed date seed (PDS) through oil extraction.

Method. The physicochemical composition and thermal behavior of RDS and PDS was determined to evaluate their usefulness for thermal energy production. Proximate and thermogravimetric analyses, Scanning Electron Microscope imaging, and different fuel properties such as Higher Heating Value (HHV), bulk, and energetic density and Fuel Value Index (FVI), were determined. Furthermore, the potential energy production from seed waste of the Mexican date industry was estimated.

Results. The RDS presented better HHV 19.33 MJ·kg-1 and energetic density 14.42 MJ·m-3, however, PDS has lower moisture 5.12% and ash content 5.89%. The FVI of PDS is more favorable than RDS, 363.81 and 208.43 respectively.

Conclusions. The potential energy production from date seeds produced in Mexico in 2018 was calculated RDS 10.17 TJ, PDS 8.04 TJ and Biodiesel 2.01 TJ and with a tendency to increase every year.

Received 23 November 2021, accepted 9 November 2022, available online 1 December 2022

This article is distributed under the terms and conditions of the CC-BY License (http://creativecommons.org/licenses/by/4.0)

1. Introduction

1The valorization of residual or waste agricultural biomass is a promising way for dealing with some of the environmental and economic problems of rural areas and does not compete with or decrease food production. Therefore, biomass has been of increasing interest for energy generation from agricultural waste, particularly through the generation of heat and power by thermochemical conversion (Demirbas, 2001).

2The fruit of the date palm (Phoenix dactylifera L.) contains a single seed that is discarded after being removed from the date pulp (Mohammad et al., 2012). Date seeds are currently considered as waste and are sent to landfills. However, it has been reported that date seed waste can be used as a suitable biomass for conversion into fermentable sugars for various applications such as bioethanol production (Hasan Ba Hamid & Ku Ismail, 2020). In the search to valorize this waste through using it as raw material for biofuel production, Hasan Ba Hamid & Ku Ismail (2020) found that it contains 27.34% lignin, 20.63% cellulose and 13.49% hemicellulose which can be hydrolysed into fermentable sugars. Due to its particular chemical composition, date seeds can be efficiently transformed to obtain biogas (Ben Yahmed et al., 2021), synthesis gas (Asfar, 2014) and biodiesel even when the amount of extracted oil is low (Azeem et al., 2016).

3One of the challenges that limits the waste valorization of raw date seeds (RDS) is their hardness compared to other seeds. The extraction of vegetable oil is a possible valorization for this residue (Virmond et al., 2013). However, it only partially solves the problem, because processing date seeds for vegetable oil extraction also generates residues. The residues remaining after oil extraction is referred to in this report as processed date seed (PDS).

4The energy value of RDS and PDS is aligned with current demand for renewable energy. There have been reports of the energy content of RDS as potentially suitable for use as biofuel (Jamil et al., 2016).

5However, it appears that no study has been conducted on the energy value of PDS. Therefore, the aim of this research was to determine the physicochemical composition and thermal behavior of RDS and PDS to evaluate their usefulness for thermal energy production. The potential energy production from seed waste of the Mexican date industry was estimated. This research may stimulate the interest of date farmers and industrialists in Mexico to use date seeds as a feedstock for renewable fuels. It could serve as a strategy to decrease the negative environmental impact associated with waste disposal from the Mexican date industry.

2. Materials and methods

2.1. Date seed sampling and sample preparation

6During the 2018 harvest season, dates were collected at the “Tamr stage” (full ripeness) approximately 29 weeks after pollination from a plantation of the ‘Medjool’ cultivar (Figure 1) located in the agricultural area of the Mexicali Valley in northwest Mexico having the typical agroclimatic conditions of the area. Twenty date fruits were randomly selected from each of five date palms for a total sample size of 100 fruits. The date seeds were removed from the flesh and soaked in clean water to free them of any adhering flesh and then were air-dried.

Figure 1. Date trees (Phoenix dactylifera L.) in an orchard in the Mexicali Valley, Mexico — Dattiers (Phoenix dactylifera L.) dans un verger de la vallée de Mexicali, Mexique.

Figure 1. Date trees (Phoenix dactylifera L.) in an orchard in the Mexicali Valley, Mexico — Dattiers (Phoenix dactylifera L.) dans un verger de la vallée de Mexicali, Mexique.

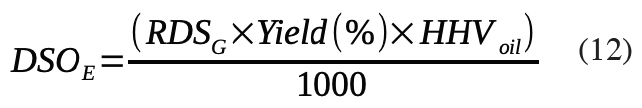

2.2. Date seed physical properties

7Seed dimension and mass. A subsample of thirty healthy, undamaged date seeds was randomly selected from the seeds harvested. Length, width, and thickness of each seed were measured with a digital caliper (Mitutoyo Corporation, Japan), and the mass of the seeds was determined using an electronic balance. The values are reported as mean ± SD.

8Oil extraction yield. The one hundred date seeds were milled using a coffee grinder to pass through 1-2 mm mesh screens and then stored at 4 °C. The oil extraction was performed according to the method described by AOAC 963.15 (AOAC, 1973). Briefly, 10 g of date seed powder was extracted with 200 ml of n-hexane in a soxhlet extractor for 6 h. The n-hexane was then removed by evaporation using a rotary evaporator for 4 h at 80 °C in a water bath. The extraction processes were performed in triplicate and the yield was expressed as percentage of oil (w/w), and the mean value and standard deviation were reported. The percentage of date seed oil in the seeds was calculated using Equation (1):

9where wc is the mass of date seed oil extracted from the sample (g) and wt is the mass of date seed processed (g).

2.3. SEM micrograph

10In order to examine the surface morphology of raw date seed powder and to identify the morphological changes occurring on the date seed surface due to the contact with n-hexane for oil removal, a Scanning Electron Microscope (SEM) JEOL JSM- 6360 was utilized. The conditions were constant at 800x, an acceleration voltage of 10 kV and a vacuum of 50 P, due to the nonconductive nature of the sample.

2.4. Proximate analysis

11Proximate analysis was performed for RDS and PDS to determine the weight percentages of moisture, volatile matter, and ash, and fixed carbon was calculated by difference. The data provided by this analysis is necessary to determine the most appropriate conversion process for energy production. The analyses were carried out in triplicate and conducted according to the respective ASTM.

12Moisture. Three melting pots that contained the samples were heated at 103 ± 2 °C for 12 h until constant mass was reached as per ASTM E871-82 (ASTM, 2019). Equation (2) was used to determine moisture.

13where M is moisture (%), A is the mass of the sample used (g), and B is the mass of the sample after heating (g).

14Volatile matter. Volatile matter is the fraction, exclusive of moisture, that is released when the fuel is heated to high temperature in the absence of air. The mass released by heating is from two sources. One is the organic or active energy fraction of the fuel, consisting of low molecular weight hydrocarbons, carbon monoxide, and hydrogen. The other is the inorganic source or inactive energy fraction of the fuel fraction, comprised of CO2, NOx, SO2, and SO3.

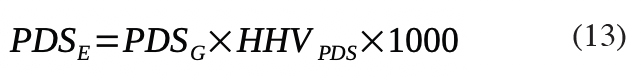

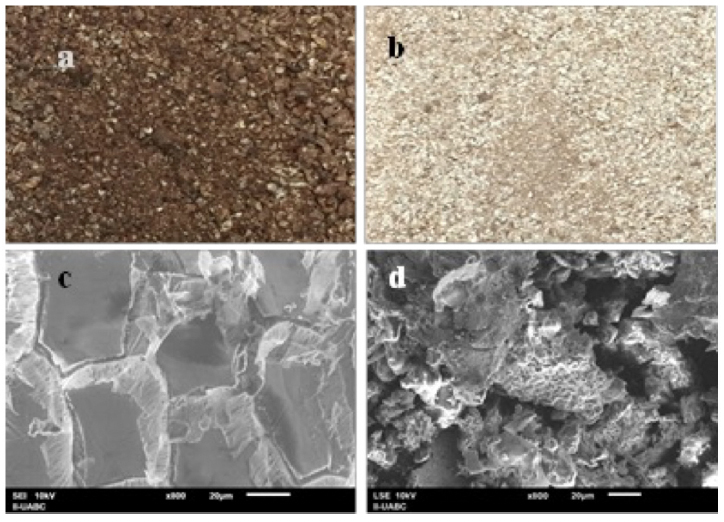

15The sample was heated in the absence of air at 950 ± 2 °C for 7 min. The melting pots were then removed from the furnace, allowed to cool, and moved to the desiccator until reaching 25 °C. Then, the mass of the melting pots was determined in accordance with ASTM E872-82 (ASTM, 2006) to calculate the mass loss with Equation (3).

16where L is the mass loss (%), A is the mass of the dry sample (g), and B is the mass of the dry sample (g) after heating.

17Finally, the percentage of volatile matter (VM) is determined through Equation (4).

18Ash. Ash is the inorganic residue remaining after the combustion of fixed carbon. It reduces heating value and combustion efficiency. A high ash content decreases heat transfer. The Ash content is expressed as the percentage of dry residue after oxidation of the sample between 580 and 600 °C for 4 h, according to ASTM D1102-84 (ASTM, 2013). Equation (5) was used to determine the ash content.

19where A is the mass of the residue after heating (g), and B is the mass of the sample used (g).

20Fixed carbon. Fixed carbon (FC) is calculated as shown in Equation (6). The higher this factor is, the easier ignition occurs and the lower the time to complete combustion is.

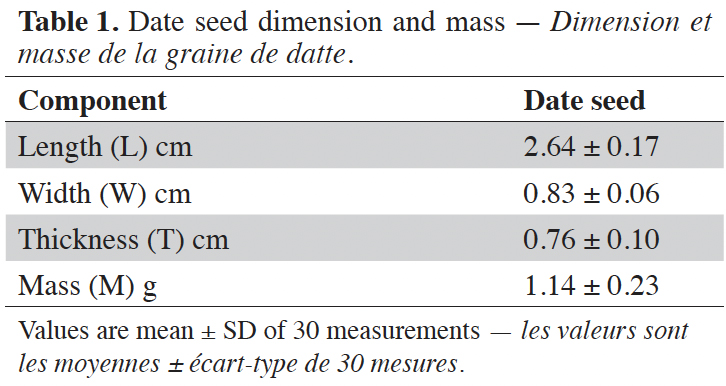

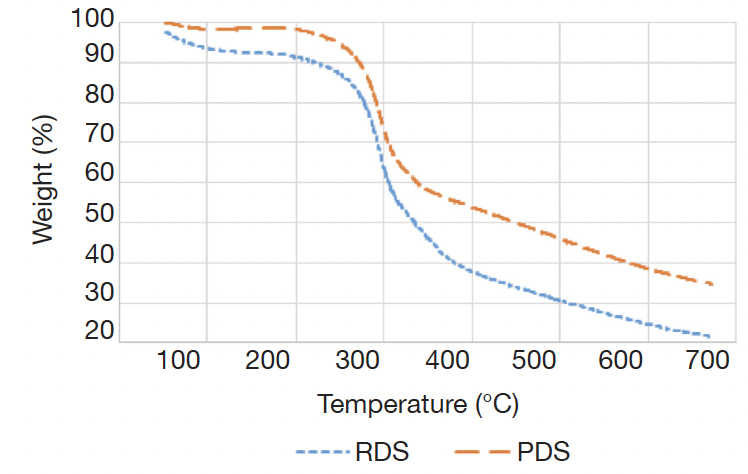

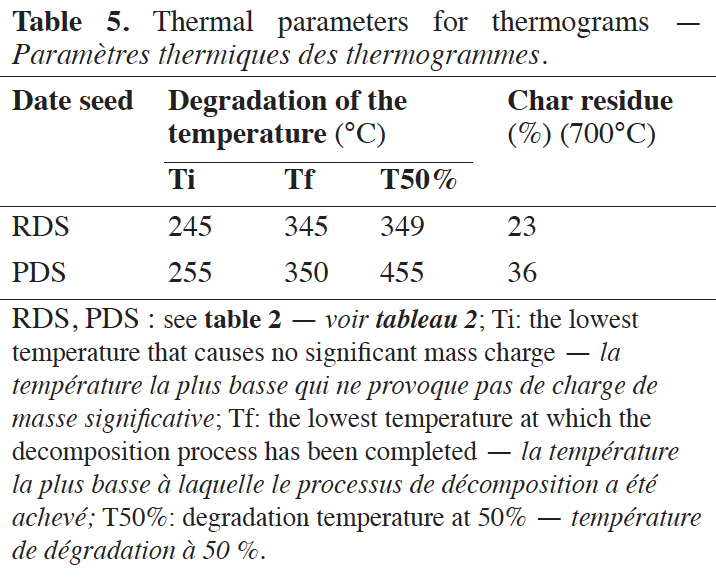

2.5. Thermal behavior

21Higher Heating Value. Higher Heating Value (HHV) determinations were made for RDS, PDS, and date seed oil by using an IKA WERKE calorimetric bomb, model C 2000 basic, according to ASTM E711-87 (ASTM, 2004). Before the analysis of the samples, the calorimeter was calibrated using benzoic acid as a standard. The analysis was carried out in triplicate, and the mean and standard deviation were reported.

22Bulk and energetic density. Bulk density of RDS and PDS were determined by filling an empty graduated cylinder at a determined volume and weighing the material. Bulk density determination of RDS and PDS used complete date seeds and the residual powder, respectively, according to ASTM D7481-18 (ASTM, 2018). The test was performed in triplicate, and the mean and standard deviation value were calculated according to Equation 7 (Owolarafe et al., 2007):

23where BD is the bulk density (kg·m-3); BM, bulk mass of date seed (g); V, test tube container volume (cm3).

24Energy density is a term defining the amount of energy available per unit of biomass, and is calculated by using the Equation (8):

25where ED is the Energy density (MJ·m-3).

26Fuel Value Index. Fuel value index is an important parameter for screening desirable fuel biomass (Sommersacher et al., 2012). It is calculated using the HHV and bulk density as positive factors, and ash and moisture content as negative factors. Calculations were made according to Equation (9) (Mierzwa-Hersztek et al., 2019).

27where FVI is the fuel value index (MJ·m-3).

28Thermal behavior. A thermogravimetric analyzer Perkin Elmer STA 6000 Simultaneous Thermal Analyzer was used to perform a thermo-gravimetric analysis (TGA). RDS and PDS powder (8 mg each) were placed in a ceramic pan to measure the weight change during heating the sample from 25 to 680 °C with a step rate of 10 °C·min-1 under atmospheric pressure with a constant nitrogen gas flow rate of 20 ml·min-1. Data was collected automatically by the instrument to obtain the weight loss rate curve.

2.6. Date production and data collection

29Data on the planted and producing area of date production and date crop production in Mexico in the period 1980 to 2018 were obtained from the agricultural statistical information system of Mexico (SIAP, 2018). The date seed was estimated as accounting for 5.67% of the total mass of date fruit (Salomón-Torres et al., 2019). The mass of date seeds produced was subsequently estimated through Equation (10).

30where RDSP is the RDS production (tons), DP is date fruit production (tons) and DSP is date seed proportion.

2.7. Date seed and oil energy estimation

31For the estimation of the energy contained in RDS, PDS, and date seed oil, the information corresponding to the production of dates in Mexico from 2014 to 2018 was used in the following equations.

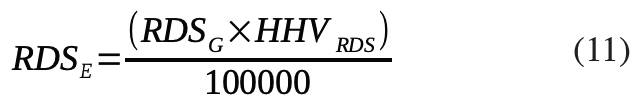

32The energy contained in RDS was calculated using Equation (11), the energy contained in the date seed oil was estimated by Equation (12), and the energy contained in the PDS with Equation (13).

33with RDSE: RDS energy (PJ); RDSG, RDS generation (tons); HHVRDS, RDS Higher Heating Value (MJ·kg-1).

34with DSOE, Date seed oil energy (MJ); RDSG, RDS generation (t); Yield (%), Yield oil fraction; HHVoil, Oil Higher Heating Value (MJ·kg-1).

35with PDSE, Date seed energy (MJ); PDSG, RDS generation (t); HHVPDS, RDS Higher Heating Value (MJ·kg-).

3. Results

3.1. Date seed physical properties

36The average of principal dimensions of date seeds are presented in table 1.

37The average oil yield extracted from date seed in the present study was 9.94 ± 0.08% w/w.

3.2. SEM morphology analysis

38At first glance, there are significant differences in color and appearance between the powders of RDS and PDS. The RDS has a dark brown color and a moisturized appearance (Figure 2a). In contrast, the PDS has an ivory white color, is porous and has a dry appearance (Figure 2b) due to the interaction with hexane during oil extraction.

39The observation on the surface morphology via SEM micrograph (800x) shows the cell microstructures of the raw date seed powder surface (Figure 2c).

40The interaction of the RDS powder with the n-hexane solvent for oil extraction resulted in the collapse of cell structure, as can be seen in the SEM micrograph (800x) (Figure 2d).

Figure 2. Date seed powder: a. before oil extraction, b. after oil extraction, c. SEM micrograph 800x before oil extraction, d. SEM micrograph 800x after oil extraction — Poudre de grains de datte : a. avant l’extraction de l’huile, b. après l’extraction de l’huile, c. Micrographie SEM 800x avant l’extraction de l’huile, d. Micrographie SEM 800x après l’extraction de l’huile.

3.3. Proximate analyses

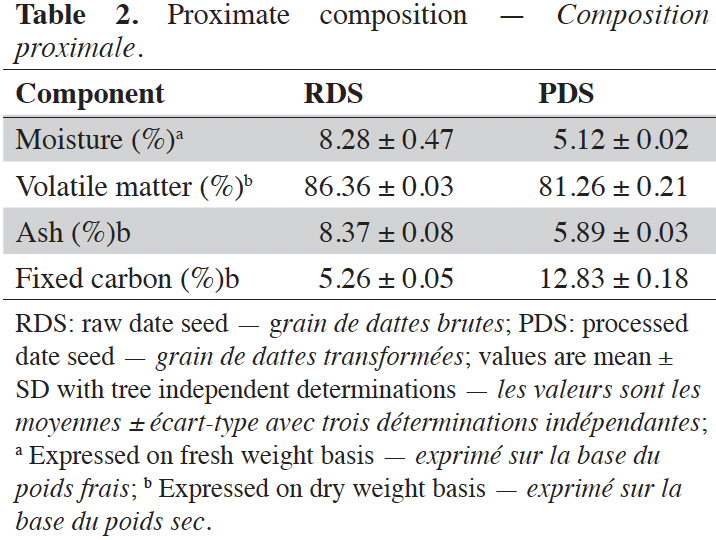

41The proximate analyses showed that the samples had different values of moisture content, volatile matter, ash, and fixed carbon (Table 2).

3.4. Fuel properties

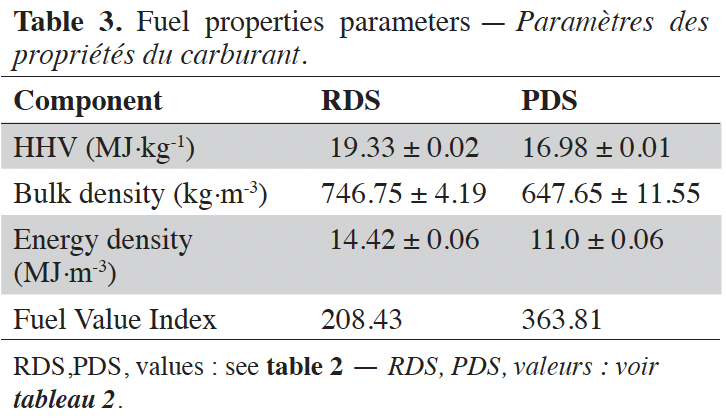

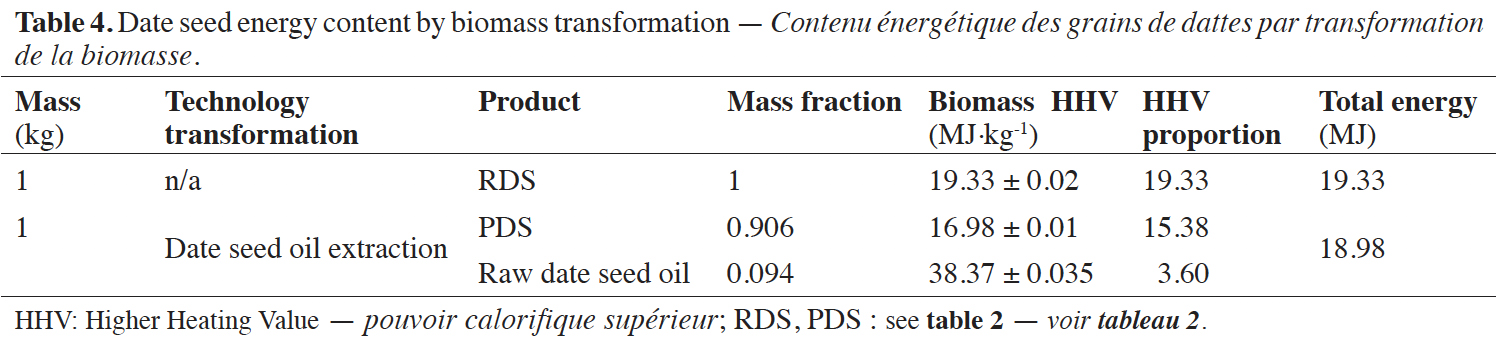

42Thermal profile. In order to assess the utilization of raw and processed date seed as an effective source of bioenergy, their thermal profiles were analyzed. Table 3 presents the values of the fuel properties parameters as an indicator of fuel quality.

43Table 4 summarizes the information related to the energy content of the raw and processed date seed, as well as the proportion into which the energy is divided and the total energy which is possible to obtain by the transformation of the date seeds.

44Thermal properties. In thermo-gravimetric analysis, the thermal behavior and weight loss measurements are used to determine the decomposition characteristics and thermal stability. Figure 3 shows the TGA thermographs of the RDS and PDS.

Figure 3. Thermograph of thermo-gravimetric analysis at a heating rate of 10 °C.min-1 — Thermographe de l’analyse thermo-gravimétrique à une rampe de chauffage de 10 °C.min-1.

Figure 3. Thermograph of thermo-gravimetric analysis at a heating rate of 10 °C.min-1 — Thermographe de l’analyse thermo-gravimétrique à une rampe de chauffage de 10 °C.min-1.

RDS, PDS : see table 2 — voir tableau 2.

45Table 5 shows the summarized results of the thermal properties of RDS and PDS determined from TGA.

3.5. Date seed generation and energy estimation

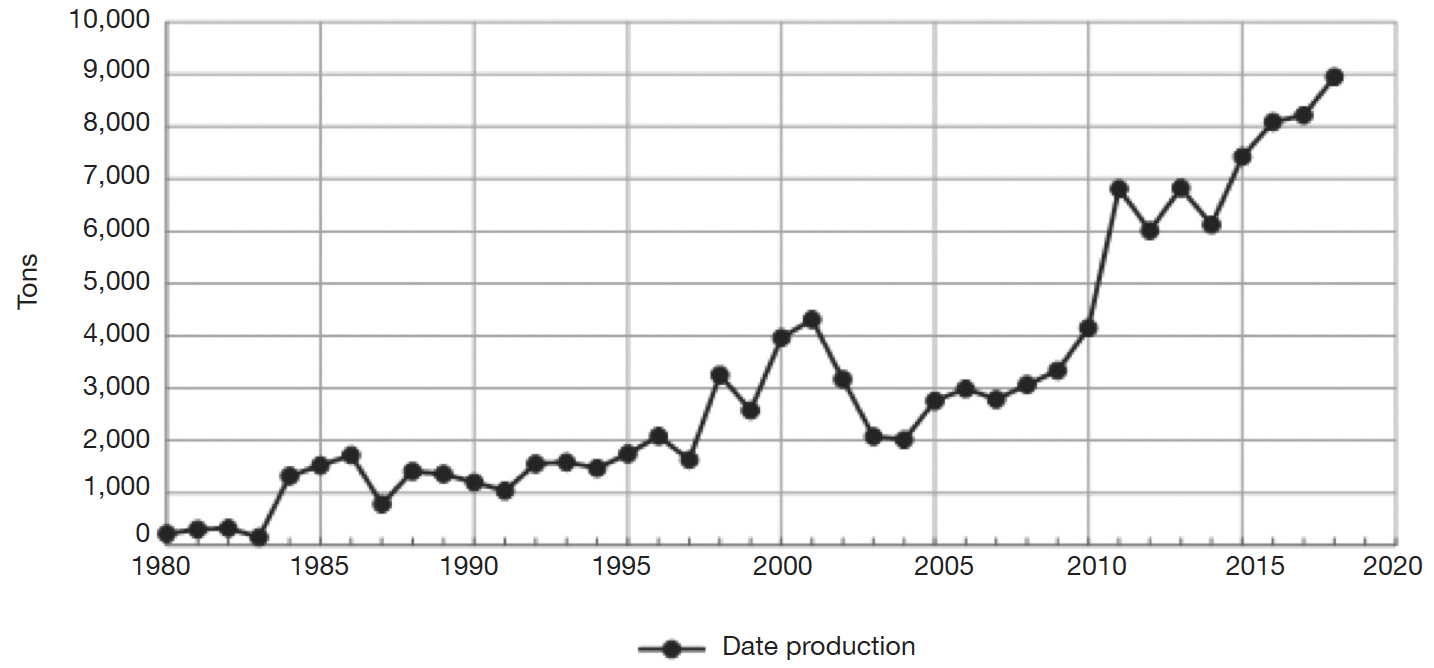

46The historical production of date fruit in Mexico is shown in figure 4.

Figure 4. Historical production of date palm fruit in Mexico — Production historique de fruits de palmier dattier au Mexique.

Figure 4. Historical production of date palm fruit in Mexico — Production historique de fruits de palmier dattier au Mexique.

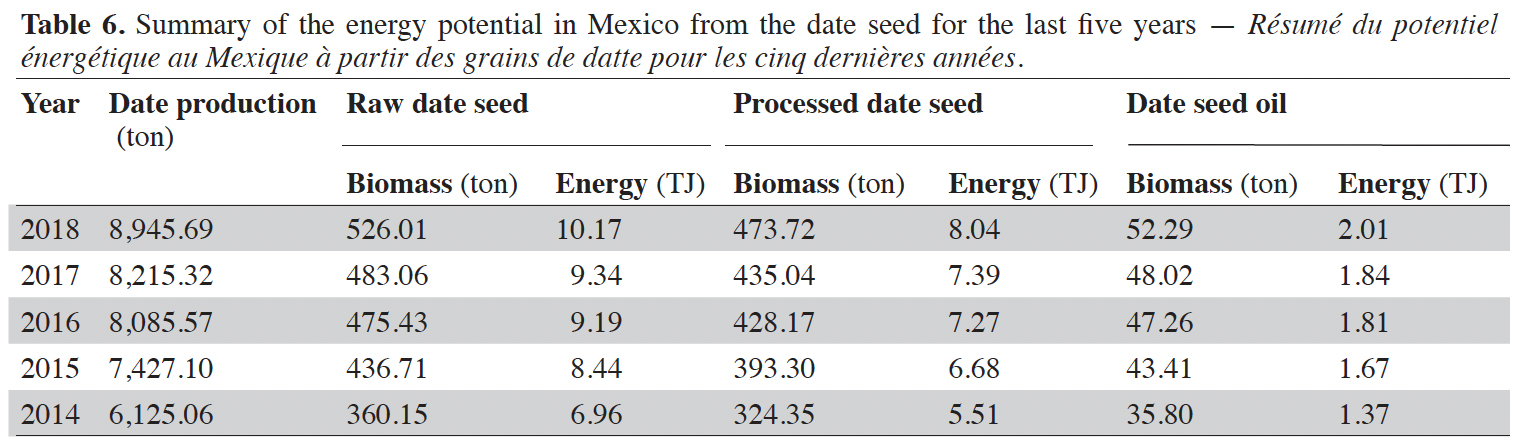

47The raw date seed generation and summary of the energy potential in Mexico was calculated and is presented in table 6.

4. Discussion

4.1. Date seed physical properties

48The date seed dimensions and mass measured for ‘Medjool’ seeds in the United Arab Emirates were reported to be 2.09 cm in length, 0.93 cm in diameter, and 1.1 g (Habib & Ibrahim, 2009). In that case, the authors reported a diameter; however, due to the proximity of width and length dimensions in the current study, these can be considered as approximating the diameter of the date seed. Thus, the seeds used in this study can be considered to approximate “typical” ‘Medjool’ seeds.

49In the section “Specification of dimensions properties for pellets” in European standard 14961-1 (UNE-EN, 2011), there is a classification of biomass pellets by dimension. The biomass pellet classification D08, with parameters of 0.8 cm ± 0.1 cm in diameter and between 3.15 and 4.00 cm in length, is the closest to date seed dimensions. The diameter of the date seed is within the parameters of the standard, although the length is 0.5 cm less than the lower limit of the standard. A visual comparison of biomass pellets and date seeds is shown in figure 5.

Figure 5. Physical comparison: a. biomass wood pellet, b. ‘Medjool’ date palm seed — Comparaison physique : a. granulés de bois de biomasse, b. grains de palmier dattier ‘Medjool’.

Figure 5. Physical comparison: a. biomass wood pellet, b. ‘Medjool’ date palm seed — Comparaison physique : a. granulés de bois de biomasse, b. grains de palmier dattier ‘Medjool’.

50The dimensions and shape of date seeds are similar to biomass pellets. Therefore, it is potentially feasible to use date seeds in automatic biomass feeding systems for energy production, which allows finer regulation of the burn rate by controlling the proportion at which fuel is added to the combustion chamber.

51The yield of oil extracted from date seed in the present study, is consistent with other reports (Fadhil et al., 2017; Devshony et al., 1992). Hence, there is an opportunity to assess the oil contained in the date seed for biodiesel production.

4.2. SEM morphology analysis

52The structural pattern of the cells is consistent with the microphotograph sections of date seed cell wall presented by Xiao et al. (2019). In addition, the particle size was reduced; the surface morphology was irregularly transformed; and a greater brightness appears on the surface of the particle, as a result of color loss by the date seed oil extraction. No SEM micrograph related to the processed date seed was found in the scientific literature as a point of comparison.

4.3. Proximate analyses

53In order to evaluate the utilization of RDS and PDS as a source of bioenergy, it is necessary to determine their performance as a biofuel through combustion.

54Moisture content in biomass has a negative effect on FVI, due to a decreasing HHV. Moreover, a moisture content below 15% has been found to inhibit anaerobic microbial activity and allow for safe long-term storage of biomass (Holm-Nielsen & Ehimen, 2016). The moisture content of RDS (8.28%) is relatively high compared with the 6.4-6.5% value reported by other authors (De la Cruz-Lovera et al., 2019; El May et al., 2012a; El May et al., 2012b). The moisture content of PDS (5.12%) is lower than that of RDS, probably because the date seed cells are collapsed by the action of the solvent, which allows water to be released into the environment. However, both RDS and PDS would be considered “dry” biomass (moisture content ≤ 12.5%); this category also includes wood chips and biomass briquettes (McKendry, 2002).

55Volatile matter content was 81.26% for PDS and 86.36 % for RDS. The volatile matter for RDS is 6.27% greater than PDS due to the presence of oil contained in the seed. The value for the volatile material of the RDS agrees with that reported by Nasser et al. (2016). Nevertheless, the volatile content of both samples is above the values previously reported, 74.1 and 76.6%, respectively (El May et al., 2012b; Sait & Salema, 2015).

56Ash is the inorganic material remaining after oxidation and is considered undesirable for several reasons: the most important being that it reduces fuel power, favors ash deposition and induces corrosion problems in the heat exchanger. The relative order of mineral concentration in date seeds reported by Bijami et al. (2020) is Ca < P < K < K < Mg < Fe < Zn < Mn < Cu. The ash content in the RDS (8.37%) was higher than in the PDS (5.89%). The scientific literature reports ash values of 1.2% (El May et al., 2012a) and 1.4% (Nasser et al., 2016), which are lower than those reported in this work. One of the reasons for this difference may be due to the quality of the irrigation water and soil which have high concentrations of minerals and natural salinity content, respectively.

57The fixed carbon content of RDS and PDS were very different from each other, being 5.26% and 12.83%. The value for PDS has no comparison points in the literature since the date seeds underwent a physical-chemical transformation during oil extraction and are not in the same condition as seeds analyzed by other researchers. The results reported in the scientific literature on fixed carbon differ from those reported in the present work which were of 5.26% for RDS. Fixed carbon values ranging from 7.7 to 24.87% have been reported (El May et al., 2012b; Mahdi et al., 2015; Sait & Salema, 2015; Nasser et al., 2016). The higher this value is, the more amount of solid materials will have to be burned and the slower the release of volatile material will tend to be, which will be verified in the TGA thermograph.

4.4. Fuel properties

58Thermal profile. The findings show that the RDS and PDS have HHV differences. The RDS HHV value, as expected, was 13.83% higher than the PDS HHV value, due to the oil contained in the raw seed. The present work reports a HHV value for RDS which is higher than that reported by other authors (Nasser et al., 2016; De la Cruz-Lovera et al., 2019) and close to that of wood pellets (20.30 MJ·kg-1) (García et al., 2017; Toscano et al., 2014), almond shell (19.49 MJ·kg-1) (Obernberger & Thek, 2004), and the average value of 20 MJ·kg-1 for biomass (Channiwala & Parikh, 2002; Jeguirim et al., 2010; Jeguirim et al., 2012). For PDS there is no reference of energetic value reported in the scientific literature as a point of comparison, but its HHV value is lower than that cited in the sources above.

59Additionally, the HHV of the date seed oil was determined in trifold, with a value of 38.37 ± 0.035 MJ·kg-1, a result that is consistent with that previously reported by Herch et al. (2014) and Fadhil et al. (2017). Date seed oil can be used as edible vegetable oil with purification treatment (Boukouada & Yousfi, 2009; Reddy et al., 2017) or transformed into biodiesel (Azeem et al., 2016; Asif et al., 2017; Farooq et al., 2018).

60The bulk density previously reported for unprocessed date seed was 590 ± 140 kg·m-3 (Mahawar et al., 2017), which is lower than reported in the present work (746.75 and 647.65 kg·m-3 for RDS and PDS, respectively). This is an advantage for transport and storage since the values are within those for biomass formulated as pellets, briquettes, and cubes (Toscano et al., 2014; García et al., 2017). The bulk density and energetic density values for RDS and PDS are noticeably different due to the different physical conditions. Indeed, the measurement of the RDS volume was performed using the whole seed whereas the PDS volume was measured as powder because of the need to crush the seed before oil extraction. The physical condition of the latter was due to the need to crush the seed before oil extraction.

61Energetic density is the energy available per unit of volume. The energetic density of date seed reported by El May et al. (2012b; 2013) was 11.4 MJ·m-3, approximately one third lower than that reported for RDS in this study (14.42 MJ·m-3). The energy density value for PDS has no reference for comparison. Interestingly, the value reported here for PDS is very close to that reported for RDS by El May et al. (2012b; 2013).

62The FVI is used as a reference that facilitates the classification of biomass to determine more comprehensively its quality as fuel. The FVI of the RDS was 208.43 and for PDS, 363.81. The lower value for RDS may be attributed to increased ash content, the most important variable adversely affecting the FVI. Contrary to what was expected from the high HHV value of RDS as compared to PDS, the latter has approximately 75% better performance as fuel than the former.

63The production of energy from date seeds, as proposed in this paper, can be done in two different ways. The production of energy from RDS is through direct combustion, as from biomass pellets. It has the advantage of not requiring any treatment and having good energy yield. Another way of obtaining energy from date seeds is through the extraction of the oil contained in the seed. This has added value for its subsequent transformation into biodiesel and the possibility to harness the energy of the remaining biomass of the processed seed by combustion. In both proposals, waste generation is considerably reduced.

64Thermal properties. A loss of mass is observed between 30 °C and 180 °C, corresponding to moisture loss from the surface in both samples. The loss of mass was 7% in the RDS sample and 2.17% in the PDS sample. Thermal decomposition continues rapidly between 180 °C to 380 °C for RDS sample and between 180 °C to 363 °C for the PDS sample, causing mass losses of 59 and 42%, respectively. This temperature range is characterized by a large release of low molecular weight volatile matter. This is the most active region of pyrolysis, where thermal decomposition of hemicellulose, cellulose, extractive substances, and part of lignin occur (Ceylan & Topçu, 2014; Sokoto & Bhaskar, 2018). The loss of mass in the pyrolysis region was lower in the PDS sample, because the oil and other substances soluble in non-polar solvents were removed during the oil extraction process (White, 1987). The final stage of thermal decomposition occurs between 370 °C and 700 °C (Barneto et al., 2010). In this temperature range, mostly lignin decomposes and more stable compounds. Therefore, the decomposition rate in the final stage is slower. The TGA thermograph of RDS was similar to that presented by El May et al. (2012a).

65The difference between the reaction temperature and interval (Ti and Tf) of RDS and PDS is only about 5 °C, with PDS having the highest temperature. However, there is a large difference in the degradation temperature of 50% of the matter, being 349 °C and 455 °C for RDS and PDS, respectively, a difference of 106 °C. The RDS degrades faster due to the presence of the oil contained in the date seed powder, unlike the PDS, which does not have date seed oil. PDS was more difficult to degrade and resulted in higher char residue (36%) than RDS (23%) due to the oil contained in the latter. The percentage of RDS carbon residue is close to that of 28.1% reported by El May et al. (2013). Moreover, for the PDS carbon residue, there is no result reported in the scientific literature to serve as comparison, so the result reported in this study can serve as a first point of reference.

4.5. Date seed generation and energy estimation

66The production of dates in Mexico is relatively low, compared to the major date producing countries worldwide such as Egypt, Iran, Algeria, Saudi Arabia, and Iraq (FAO, 2019).

67Date production and seed generation. The planted area of date production is increasing rapidly in Mexico. In 2018, the planted area was 2,922 ha, and the producing area was 1,572 ha. This difference is due to the fact that the female date palm starts producing dates at 4 to 6 years of age and reaches full production within 15 to 20 years (Nixon & Carpenter, 1978).

68By 2018, there was a difference of approximately 50% between the planted and producing area. Therefore, the production of dates in the coming years will gradually increase as the existing date palms enter productive life until reaching a constant production when the palms are mature.

69From 2011 to 2014, the date production fluctuated. However, in 2014 the production increased and reached 8,945 tons by 2018, reflecting an increase of 45%. The date seed generation was calculated to have increased by the same proportion, from 360.15 to 524.01 tons. The corresponding potential energy derived from raw date seeds increased from 6.96 TJ to 10.17 TJ. If the date seeds were processed, the potential energy derived from processed date seed biomass would increase from 5.51 to 8.04 TJ and from date seed oil from 1.37 to 2.01 TJ, for a total increase from 6.88 to 10.05 TJ. It represents a considerable amount of waste biomass and bioenergy potential that were unexploited.

5. Conclusions

70Due to the growth of date production in Mexico, producers need to consider sustainable management of date seeds rather than disposal as waste in landfills. The obtained HHV and comparison to other biomass fuels indicated that RDS and PDS can be considered as viable sources for energy production. However, the ash content is high, compared to other types of biomasses. This could lead to some problems, such as reduced fuel power, ash deposition and corrosion problems in the heat exchanger.

71RDS can be used as a natural biomass pellet for combustion and date seed oil extraction. Energy can also be obtained from PDS by using the oil for biodiesel transformation and the solid fraction for combustion. RDS can produce slightly more energy, but the production of biodiesel from PDS may be desirable.

Acknowledgements

72The authors extend their sincere appreciation to Corporative RUVA, for the use of their facilities in the realization of this study. To Rafael Quirarte-Gutierrez and Roberto Torres-Yescas from Rancho “La Vaca” for their support and advice. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors. Finally, the authors declare no competing financial interests.

Bibliographie

Al Asfar J., 2014. Gasification of solid waste biomass. Jordan J. Mech. Ind. Eng., 8(1), 13-19.

AOAC, 1973. Fat in cacao products - Soxhlet extraction method, AOAC 963.15. Washington, DC: Association of Official Analytical Chemists.

Asif S., Ahmad M., Zafar M. & Ali N., 2017. Prospects and potential of fatty acid methyl esters of some non-edible seed oils for use as biodiesel in Pakistan. Renewable Sustainable Energy Rev., 74, 687-702, doi.org/10.1016/j.rser.2017.02.036

ASTM, 2004. Standard test method for gross calorific value of refuse-derived fuel by the bomb calorimeter, E711-87. West Conshohocken, PA, USA: ASTM International, doi.org/10.1520/E0711-87R04

ASTM, 2006. Standard test method for volatile matter in the analysis of particulate wood fuel, D 872-82. West Conshohocken, PA, USA: ASTM International, doi.org/10.1520/E0872-82R19

ASTM, 2013. Standard test method for ash in wood, D1102-84. West Conshohocken, PA, USA: ASTM International, doi.org/10.1520/D1102-84R13

ASTM, 2018. Standard test methods for determining loose and tapped bulk densities of powders using a graduated cylinder, D7481-18. West Conshohocken, PA, USA: ASTM International, doi.org/10.1520/D7481-18

ASTM, 2019. Standard test method for moisture analysis of particulate wood fuels, E871-82. West Conshohocken, PA, USA: ASTM International, doi.org/10.1520/E0871-82R19

Azeem M.W. et al., 2016. Production of biodiesel from low priced, renewable and abundant date seed oil. Renewable Energy, 86, 124-132, doi.org/10.1016/j.renene.2015.08.006

Barneto A.G., Carmona J.A., Alfonso J.E.M. & Serrano R.S., 2010. Simulation of the thermogravimetry analysis of three non-wood pulps. Bioresour. Technol., 101, 3220-3229, doi.org/10.1016/j.biortech.2009.12.034

Ben Yahmed N. et al., 2021. New sustainable bioconversion concept of date by-products (Phoenix dactylifera L.) to biohydrogen, biogas and date-syrup. Int. J. Hydrogen Energy, 46(1), 297-305, doi.org/10.1016/j.ijhydene.2020.09.203

Bijami A., Rezanejad F., Oloumi H. & Mozafari H., 2020. Minerals, antioxidant compounds and phenolic profile regarding date palm (Phoenix dactylifera L.) seed development. Sci. Hortic., 262, 109017, doi.org/10.1016/j.scienta.2019.109017

Boukouada M. & Yousfi M., 2009. Phytochemical study of date seeds lipids of three fruits (Phoenix dactylifera) produced in Ouargla region. Ann. Fac. Sci. Sci. Ing., 1, 66-74.

Ceylan S. & Topçu Y., 2014. Pyrolysis kinetics of hazelnut husk using thermogravimetric analysis. Bioresour. Technol., 156, 182-188, doi.org/10.1016/j.biortech.2014.01.040

Channiwala S.A. & Parikh P.P., 2002. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel, 81, 1051-1063, doi.org/10.1016/s0016-2361(01)00131-4

De la Cruz-Lovera C. et al., 2019. Date seeds (Phoenix dactylifera L.) valorization for boilers in the Mediterranean climate. Sustainability, 11(3), 711, doi.org/10.3390/su11030711

Demirbaş A., 2001. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manage., 42(11), 1357-1378, doi.org/10.1016/s0196-8904(00)00137-0

Devshony S., Eteshola E. & Shani A., 1992. Characteristics and some potential applications of date palm (Phoenix dactylifera L.) seeds and seed oil. J. Am. Oil Chem. Soc., 69, 595-597, doi.org/10.1007/bf02636115

El May Y. et al., 2012a. Measurement of gaseous and particulate pollutants during combustion of date palm wastes for energy recovery. Aerosol Air Qual. Res., 12(5), 814-825, doi.org/10.4209/aaqr.2012.03.0056

El May Y. et al., 2012b. Study on the thermal behavior of different date palm residues: characterization and devolatilization kinetics under inert and oxidative atmospheres. Energy, 44(1), 702-709, doi.org/10.1016/j.energy.2012.05.022

El May Y. et al., 2013. Experimental investigation on gaseous emissions from the combustion of date palm residues in laboratory scale furnace. Bioresour. Technol., 131, 94-100, doi.org/10.1016/j.biortech.2012.12.120

Fadhil A.B., Alhayali M.A. & Saeed L.I., 2017. Date (Phoenix dactylifera L.) palm stones as a potential new feedstock for liquid bio-fuels production. Fuel, 210, 165-176, doi.org/10.1016/j.fuel.2017.08.059

FAO, 2019. Food and agriculture data. Roma: FAO.

Farooq M. et al., 2018. Biodiesel production from date seed oil (Phoenix dactylifera L.) via egg shell derived heterogeneous catalyst. Chem. Eng. Res. Design, 132, 644-651, doi.org/10.1016/j.cherd.2018.02.002

García R., Pizarro C., Lavín A.G. & Bueno J.L., 2017. Biomass sources for thermal conversion. Techno-economical overview. Fuel, 195, 182-189, doi.org/10.1016/j.fuel.2017.01.063

Habib H.M. & Ibrahim W.H., 2009. Nutritional quality evaluation of eighteen date pit varieties. Int. J Food Sci. Nutr., 60, 99-111, doi.org/10.1080/09637480802314639

Hasan Ba Hamid H.S. & Ku Ismail K.S., 2020. Optimization of enzymatic hydrolysis for acid pretreated date seeds into fermentable sugars. Biocatal. Agric. Biotechnol., 24, 101530, doi.org/10.1016/j.bcab.2020.101530

Herch W., Kallel H. & Boukhchina S., 2014. Physicochemical properties and antioxidant activity of Tunisian date palm (Phoenix dactylifera L.) oil as affected by different extraction methods. Food Sci. Technol., 34(3), 464-470, doi.org/10.1590/1678-457x.6360

Holm-Nielsen J. & Ehimen E.A., 2016. Biomass supply chains for bioenergy and biorefining. Cambridge, UK: Woodhead Publishing, doi.org/10.1016/c2014-0-01700-5

Jamil F. et al., 2016. Optimization of oil extraction from waste “Date pits” for biodiesel production. Energy Convers. Manage., 117, 264-272.

Jeguirim M., Dorge S., Loth A. & Trouvé G., 2010. Devolatilization kinetics of Miscanthus straw from thermogravimetric analysis. Int. J. Green Energy, 7(2), 164-173, doi.org/10.1080/15435071003673641

Jeguirim M. et al., 2012. A new valorisation strategy of olive mill wastewater: impregnation on sawdust and combustion. Resour. Conserv. Recycl., 59, 4-8, doi.org/10.1016/j.resconrec.2011.03.006

Mahawar M.K. et al., 2017. Determination of some physical properties of date palm fruits (Cv. Khadrawy and Medjool). Acta Agrophys. J., 24(2), 271-277.

Mahdi Z., El Hanandeh A. & Yu Q., 2015. Date palm (Phoenix dactylifera L.) seed characterization for biochar preparation. In: Proceedings of the 6th International Conference on Engineering, Project, and Production Management (EPPM2015), September 2015, Gold Coast, Queensland, Australia, 130-138.

McKendry P., 2002. Energy production from biomass (part 1): overview of biomass. Bioresour. Technol., 83(1), 37-46, doi.org/10.1016/s0960-8524(01)00118-3

Mierzwa-Hersztek M., Gondek K., Jewiarz M. & Dziedzic K., 2019. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J. Mater. Cycles Waste Manage., 21, 786-800, doi.org/10.1007/s10163-019-00832-6

Mohammad U.H., Uddin U. & Mohammad N.I., 2012. The utilization of waste date seed as bio-oil and activated carbon by pyrolysis process. Adv. Mech. Eng., 1(4), 1-6, doi.org/10.1155/2012/316806

Nasser R.A. et al., 2016. Chemical analysis of different parts of date palm (Phoenix dactylifera L.) using ultimate, proximate and thermo-gravimetric techniques for energy production. Energies, 9(5), 374.

Nixon R.W. & Carpenter J.B., 1978. Growing dates in the United States. Bulletin no. 207. Washington, DC: United States Department of Agriculture, US Department of Agriculture.

Obernberger I. & Thek G., 2004. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behavior. Biomass Bioenerg., 27, 653-669, doi.org/10.1016/j.biombioe.2003.07.006

Owolarafe O.K., Olabigeand T.M. & Faborode M.O., 2007. Macro-structural characterisation of palm fruit at different processing conditions. J. Food Eng., 78, 1228-1232, doi.org/10.1016/j.jfoodeng.2006.01.024

Reddy M.K. et al., 2017. Study on physico-chemical properties of oil and powder of date palm seeds (Phoenix dactylifera). Int. J. Curr. Microbiol. Appl. Sci., 6(12), 486-492, doi.org/10.20546/ijcmas.2017.612.059

Sait H.H. & Salema A.A., 2015. Microwave dielectric characterization of Saudi Arabian date palm biomass during pyrolysis and at industrial frequencies. Fuel, 161, 239-247, doi.org/10.1016/j.fuel.2015.08.058

Salomón-Torres R. et al., 2019. Nutritional assessment, phytochemical composition and antioxidant analysis of the pulp and seed of ‘Medjool’ date grown in Mexico. PeerJ, 7, e6821, doi.org/10.7717/peerj.6821

SIAP, 2018. Anuario estadístico de la producción agrícola, https://nube.siap.gob.mx/cierreagricola/ (08/05/2019).

Sokoto A.M. & Bhaskar T., 2018. Pyrolysis of waste castor seed cake: a thermo-kinetics study. Eur. J. Sustain. Dev. Res., 2(2), 18, doi.org/10.20897/ejosdr/81642

Sommersacher P., Brunner T. & Obernberger I., 2012. Fuel indexes: a novel method for the evaluation of relevant combustion properties of new biomass fuels. Energy Fuel, 26(1), 380-390, doi.org/10.1021/ef201282y

Toscano G., Duca D., Amato A. & Pizzi A., 2014. Emission from realistic utilization of wood pellet stove. Energy, 68, 644-650, doi.org/10.1016/j.energy.2014.01.108

UNE-EN, 2011. Solid biofuels - Fuel specifications and classes - Part 1: General requirements. Official Method UNE-EN 14961-1. Madrid: UNE-EN.

Virmond E., Rocha J.D., Moreira R.F.P.M. & José H.J., 2013. Valorization of agroindustrial solid residues and residues from biofuel production chains by thermochemical conversion: a review, citing Brazil as a case study. Braz. J. Chem. Eng., 30(2), 197-230, doi.org/10.1590/s0104-66322013000200001

White R.H., 1987. Effect of lignin content and extractives on the higher heating value of wood. Wood Fiber Sci., 19(4), 446-452.

Xiao T.T. et al., 2019. Emergent protective organogenesis in date palms: a morpho-devo-dynamic adaptive strategy during early development. Plant Cell, 31(8), 1751-1766, doi.org/10.1105/tpc.19.00008