- Portada

- Volume 14 (2010)

- numéro 4

- Geotraceability: an innovative concept to enhance conventional traceability in the agri-food chain

Vista(s): 0 (0 ULiège)

Descargar(s): 0 (0 ULiège)

Geotraceability: an innovative concept to enhance conventional traceability in the agri-food chain

Notes de la rédaction

Received on May 14, 2008; accepted on June 28, 2010

Résumé

La géotraçabilité : un concept innovant pour valoriser les données de traçabilité dans les filières agro-alimentaires. Avec la mondialisation des échanges, le citoyen est devenu un consommateur averti, exigeant quant à l'origine de la nourriture qu'il consomme et à la protection de l'environnement dans lequel elle est produite. Le concept de géotraçabilité qui est présenté dans cet article répond à cette demande en associant des informations géographiques aux données de traçabilité classique. L’utilisation d’informations géographiques relatives à l’environnement des parcelles de production repose non seulement sur l’exploitation d’outils d’analyse spatiale disponibles dans la plupart des systèmes d'information géographiques (SIG), mais aussi sur le développement d’outils spécifiques comme le géo-identifiant ou les géo-indicateurs. Cet article décrit aussi les caractéristiques et la méthodologie pour implémenter un système de gestion de l’information géographique associée aux systèmes de traçabilité. Enfin, les potentialités liées à l’utilisation de systèmes de géotraçabilité dans les chaines agro-alimentaires sont analysées, en particulier pour la gestion des situations de crise ou pour venir en appui aux processus de certification des produits de qualité différenciée.

Abstract

With the globalization of trade, people have become enlightened and demanding consumers as regards the origin of their food and the environment in which it is produced. The concept of geotraceability described in this article responds to that requirement by combining geographical information with conventional traceability data. The inclusion of geographical information relating to the environment of the production plots is based not only on exploiting some functionalities of spatial analysis tools that exist in geographical information systems (GIS) but also on developing specific tools such as a geoidentifier and geoindicators. This article also describes the characteristics and methods of implementing a geographical information management system linked with traceability information. Lastly, the potential for using geotraceability systems in supply chains is analyzed, in particular for consumer warnings in cases of food crisis and assistance for certification of differentiated quality agricultural products.

Tabla de contenidos

1. Introduction

1Recent food safety problems, together with growing demand for differentiated quality products that are guaranteed healthy for consumers, have brought the traceability of food products to the forefront of the public arena. In response to these expectations the authorities in most countries have adopted laws and directives that impose restrictive measures upon firms operating in food production and marketing. At European level, for example, Regulation (EC) no.178/2002 introduced on 1st January 2005 lays down the general principles and requirements of the food law. The aim of these provisions is to ensure a high level of protection for human health and consumer interests, while at the same time ensuring the efficient functioning of the single European market. A further aim of the legislation is to organize the traceability of products entering the supply chain, to guarantee a minimum level of food quality and, to a lesser extent, to enable certain types of products to be differentiated on the basis of their method of production or geographical origin.

2In practice, the introduction of traceability systems has to a great extent been favored by innovative developments in data acquisition and data management technologies all along the production and product lot tracing chains (Hobbs, 2004). Despite the evident efforts of standardization undertaken by the different food chains, the information generally gathered in traceability systems still present a number of management problems mainly due to the wide variety of systems adopted by the various operators. Consequently, these information are often difficult to understand and to read for people not directly involved in data processing (e.g. consumers, food control agencies, etc.). Another important drawback of such systems is the declaratory nature of the information collected on a mandatory or voluntary basis. It is in fact difficult to check the information without recourse to control systems (chemical analyses, audits) which are complex and expensive to set up.

3The most commonly used traceability systems attempt to describe a series of events and, as ISO 8402 standard states, to enable “the history, use or location of an entity to be traced by means of identifications recorded throughout a complete or partial production chain”. In the particular case of the agri-food sector, the production chain extends from the sowing of a crop to harvest, transport, storage, processing and distribution and ends with the sale of the finished product to the consumer. In this case the drawback of a conventional traceability system is that it does not transmit along the agri-food chain any specific information about the environment (direct or indirect) of the field where a product lot was produced. These information, which are “invisible” to agri-food chain operators and thus to consumers, are currently not exploited or valorized. Nonetheless, it could provide additional information about product quality, harmlessness to human health and specificities due, for example, to the place of production, soil characteristics, etc.

4To date, only very superficial attention has been paid to geography in traceability systems. A study carried out for the European Commission (Anon., 2002) nevertheless showed that consumers are becoming increasingly discerning and would like to have more detailed information about what they buy, in particular the origin of the product or the production method used. Consumers are sensitive not only to the possible effects of the environment on the production place, i.e. the “agricultural parcel” or plot of land (dioxin pollution, coexistence of GMOs with other crops, etc.) but also, conversely, the impact of production on the environment (environmentally friendly production systems).

5Starting from these considerations, a concept, namely geotraceability, has been defined to supplement the conventional traceability system. The bases of this concept were defined within the framework of two research projects co-financed by the European Union in 2002 (GeoTraceAgri – IST 2001-34281) and in 2004 (GTIS-CAP – SSA 006468). The former was aimed at defining geotraceability (Debord et al., 2005) and the latter at applying the concept in the context of the Common Agricultural Policy (CAP). This approach not only ensures the traceability of a production lot but also guarantees its geographical origin and, above all, allows a product to be qualified by placing it in its agri-environmental context.

6After reviewing a few aspects of the general context of traceability in the agri-food industry and in particular at farm level, this article aims to define geotraceability and the key components of its application. The notions of geoidentifier, geoindicator and geographical information management system combined with traceability information will successively be developed. The conditions of implementation and prospects for use will also be explored.

2. Traceability in the food chain

2.1. General context

7In order to harmonize the regulations and recommendations on hygiene and food safety, the ISO (International Organization for Standardization) established in 2005 the general principles and the requirements to implement a traceability system within an enterprise in a set of standards called ISO 22000. These standards are intended for all the operators in the food chain who wish to show that they have mastered food safety management. A traceability system must notably enable a product’s history to be traced back through all the stages in the production, processing and distribution of foodstuff or animal feed, or a substance intended to be or likely to be incorporated into food. Following ISO recommendations, this system must be independent of the type of product and the production system used. It must be globally applicable to a specific sector or, more simply, to a single link in the chain (Moe, 1998).

8From the user’s point of view, traceability can be defined as tracking products in terms of quality (this is referred to as product traceability) and quantity (this is called logistical traceability) in space and time. From an information management point of view, setting up a traceability system in a supply chain means systematically linking a data flow with a physical flow. The aim is to be able at any time to find the predetermined data relating to product lots or groups of product lots from one or more key identifiers.

9With regard to traceability it has to be said that there are considerable differences between the approaches adopted in different parts of the world. U.S. traceability systems for example is motivated by economic incentives whose expected benefits include lower cost distribution systems, reduced recall expenses and expanded sales of high-value products (Golan et al., 2004). In Japan, the government promotes the development and use of food traceability systems and the integration of traceability systems with agricultural risk management systems in order to improve food safety amongst food operators (Nanseki et al., 2008). The European Union has adopted a legislative, global and integrated approach to a risk assessment system covering all food products, of both animal and plant origin. Since 2005 and the publication of regulation EC no.178/2002, the European Union has required the food industries to guarantee the traceability of products used in food manufacture for human or animal consumption. Several European countries go further by requiring an internal traceability system to be set up for each level in the production chain.

10Despite the requirements of the regulations and directives introduced, it is nevertheless clear that, except for the case of organic farming and agricultural products under a quality label or GMO crops, international and/or national legislations pay scant attention to information upstream of the first operator in the agri-food chain. However, such information can play an important role in the process of withdrawing lots from the food chain, as it enables to pinpoint their geographical origin and the environment of their production place.

11Although restrictive for enterprises, the widespread implementation of a traceability system has many advantages for both business and the consumer. It acts as a back-up to specific initiatives by the food safety agencies and also increases communication between operators in the agri-food chain. Hobbs (2004) has shown that traceability could be used as a marketing tool and has a favorable influence on sales, notably if the firm offers a product which is strongly differentiated from similar products in the same category on the market. In this case, a firm can gain significant competitive advantage over its rivals who have not implemented such a system, by offering strongly differentiated products on a traditional market. Unfortunately, this advantage diminishes as the other operators in the sector start to implement a traceability approach. To retain that competitive advantage, a firm has to take further initiative by developing the integration of additional and specific information into the traceability data flow. Continuous integration of factual data such as geographical data, is likely to add value to products.

2.2. Traceability at farm level

12At farm level, information management are traditionally linked with technical or economic farm management. To satisfy the requirements of their economic and institutional partners, farmers have progressively been forced to devote more and more time gathering and distributing all kinds of information on their production activities. Such information have to comply with a whole series of specifications laid down by supermarkets, the food processing industry and even collectors’ organizations. Farmers have thus been obliged to formalize the way that information are managed in order to meet their customers’ expectations. The solutions offered to farmers currently promote the design of information management systems that integrate farm management with traceability management. The application of Regulation EC no.178/2002 has reinforced the need to make such tools available and as a result, traceability is currently a big issue for agricultural producers. At the same time, traceability has also become a key component of the internal quality management system. The conditions of implementation of that system may vary greatly from one production sector or operator to another.

13Farm level traceability systems aim primarily at describing the growing conditions and the resources used at production unit (field) level, from soil preparation for crop sowing through to harvest. They need to be documented for the purposes of controls and inspections by the food authorities and public or private certification bodies. In practice, such traceability systems should be considered as an integral part of the production chains where quantities of data characterizing a product are recorded, thus enabling that product to be clearly identified at any time. Even if such systems include components to enable geographical information to be taken into account, such as a farm map or parcel limits, they should above all be regarded as mapping tools to supplement conventional traceability. Likewise, information directly relating to the context or the environment of production plots are not generally taken into consideration and are rarely exploited in the agri-food chain.

14Like any system, farm level traceability systems have their deficiencies. One of these is that the data available are principally declaratory data that are encoded or entered in a register on a voluntary basis by the user. Without questioning the data collection system, it has to be said that traceability systems are essentially based on confidence between producers and the downstream operators/stakeholders in the agri-food processing chain. It may readily be imagined that errors or falsified information could be supplied in a way that makes the fraud hard to detect.

3. Geographical traceability

3.1. Use of geographical information

15Although the principle of traceability is now well accepted or put into practice by all the operators/stakeholders in the agri-food chain, some people (Boisvert et al., 2005) nevertheless think that the approach needs to be taken further, by trying to develop traceability methods and systems that enable both the geographical origin and the method of production of foodstuffs to be certified.

16For the time being, however, it is difficult, for customers or external agri-food chain operators/stackeholders, to determine quickly and accurately the geographical origin of products despite the availability of analytical methods for validating a certified geographical origin in the case of certain agricultural products. Pattern recognition techniques, phylogenetic distance analyses, isotope ratios and microbial analyses are performed for tracing the geographical origin of cheeses (Mauriello et al., 2003; Pillonel et al., 2003; Bonizzi et al., 2007; Suhaj et al., 2008), poultry meat or dried beef (Franke et al., 2005; 2008; Prache et al., 2005; Schwägele, 2005) and olive oils (Zunin et al., 2005). The term of geographical traceability is defined here as the signature pertaining to the geographical origin of a sample. Such methods deliver a series of parameters that can be compared with mean values observed in the same region. Apart from the fact that such techniques are not suited to all agricultural products, they only permit post-production control in order to validate declaratory information (for instance, in order to guarantee that products come from a particular production area). Moreover, the geographical area concerned may be very large and the production area may only be roughly delimited.

17In the context of traditional traceability schemes at the farm level, geographical information are very often limited to coordinates of the farm or the field limits. Collecting additional spatial data requires a considerable investment of time, and interpreting these data for traceability purposes is not easy, because of the lack of integration of systems among the operators of a particular production area. That accounts for the present low level of use of geographical information as a traceability support. Geotraceability notably makes the information more visible all along the food processing chain.

18As mentioned with regard to traceability at farm level, the use of data processing applications that can process geographical information is becoming more widespread. In parallel to this development, geographical data are becoming increasingly accessible, in particular due to the generalization of spatial data infrastructures and the success of geo-portals like the French Geoportail (http://www.geoportail.fr/) or the Google Earth tools (http://earth.google.com). These new tools all offer fresh opportunities for enriching conventional traceability systems.

3.2. The concept of geotraceability

19Geotraceability can be defined as the ability to trace, with the aid of specific management systems, geographical information linked to traceability information, all along agro-food chains. Geotraceability exploits the complementary nature of traceability data and geographical data, through the use of specific information management techniques and systems. In other words, geotraceability combines the functionalities of a conventional traceability system and the functionalities of a geographical information system (GIS) in order to enhance the traceability information by placing it in its agri-environmental context (soil, regional characteristics, catchment areas, etc.).

20The aim of geotraceability is to enable an operator in the food chain to identify, with the aid of the plot coordinates, the characteristics of the direct and indirect environment of the production area. A geotraceability system must therefore be able to document the history of events occurring in the environment of an agricultural production unit that may have affected the agricultural product, from sowing through to harvest.

21The “agricultural parcel”, or plot, is the basic unit of agricultural management at the farm level. Conventionally, it is also the basic unit of geotraceability, being directly linked to the production unit (represented by the resulting product lot). The parcel is therefore considered to be a georeferenced representation of a homogeneous cultural whole, not of a cadastral element (which may not match the agricultural reality). The parcel is also considered to be the basis of the product lot entering the food chain.

22The information about the environment of the parcel may comprise various types of geographical data, such as the coordinates of particular geographical objects (catchment point, road network, protected area, industrial zone, etc.) or thematic data (meteorological or agri-environmental data, soil maps, geological maps, hydrography, digital elevation model, etc.). Such information may also be supplemented by a temporal dimension (e.g. anthropic activities that have impacted on a plot in the past may not become evident until a subsequent growing season).

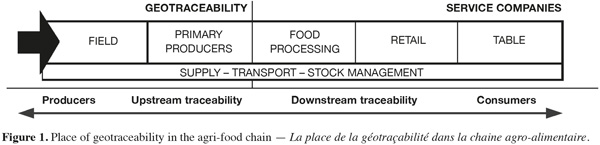

23The information needed for geotraceability concern mainly the upstream side of the food processing chain (Figure 1). By “upstream” is meant principally the “farm” and “primary collector” levels involving a number of farms. The reason for this restriction is that the environment of the parcel ceases to have a direct influence over the product lot after harvest.

24It should be noted here that traceability does not necessarily start at the farm, but also involves the suppliers of inputs of various origins (for example, seed, manure, fertilizers and pesticides) which are upstream of the farm. However, the concept of geotraceability restricts its scope to the farm level.

3.3. The notion of geoidentifier

25Within a traceability system, a physical flow (product lot) is linked to a data flow (lot of product characteristics). In order to link that both flows, the traceability system needs an identifier, represented in the form of an unique code. That code enables a product, a piece of information or a record to be identified at any time in the supply chain using a simple query to the system. To meet the needs of the agri-food industry and international trade, different solutions for coding the location of a production unit have been proposed. For example, the UAID (Unique Area/Address Identification) is a patented concept (http://geopin.org) for the identification of a production unit with reference to a string of 22 characters that can readily be converted into a barcode. The basic principle of this type of geoidentifier is that each user can easily decode it in order to determine the geographical origin of a lot precisely. This code is also used for locating and identifying farms registered in the EurepGAP program. Similarly, the PIDC (Property Identification Code) is another patented concept (http://www.scoringag.com) that enables the position of any point of interest on a traceability chain worldwide to be defined. This system uses a centralized database which provides access to information allowing the origin of products to be certified simply by making a query and enabling products to be removed from the distribution chain in case of crisis.

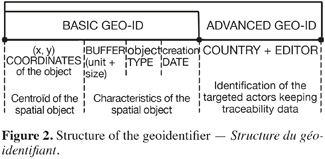

26Unfortunately these geographical identifiers are not open access systems and do not meet all the constraints of geotraceability. In the case of a geotraceability system, it must be possible to put the product lot back into the context of its production environment. Consequently, for traceability to have a geographical dimension, the product lot has to be linked to a geographical object, in this particular case the plot/parcel where it was produced. As the size and the shape of this object may vary from one growing season to another, it is important to have an identifier containing administrative and geographical information to characterize and to identify it in space and time. The identifier must also be easy to implement in standardized fashion in existing farm management and traceability system. It must also contain a minimum of information identifying the firm managing the traceability system.

27A general geoidentifier structure can be defined, based on two complementary components (Figure 2). The first component (basic geoidentifier) contains information about general characteristics of the geographical object. It comprises a geographical part containing the coordinates (for example the centroïd of the object), the size and the type of the object and the date of the identifier creation that locate the object in space and time independently of the traceability data. This part of the identifier allows any user to access the various public sources of information available on geographical portals, to perform basic spatial operations if necessary (i.e. spatial intersection, calculation of distances) in order to recreate at any moment the agri-environmental context without necessarily having to have access to traceability data.

28The geoidentifier should also contain information (advanced GEO-ID) about the code editor or the operator holding traceability data for the production unit (administrative data, crop histories, fertilizer application, etc.).

29Using the geoidentifier thus defined offers a number of advantages, specifically that of enabling all operators in the supply chain (from producer to consumer) to determine and visualize the production area of a product lot without involving an intermediary. This perceptibly shortens the time taken to identify the production area of a lot. For instance, lots from a contaminated area can be readily identified and quickly withdrawn from the market without having to set up complex management systems, unlike a conventional system where the information have to be transmitted up and then back down through all the operators in the chain in order to identify the production area.

30In the same way that a geoidentifier is assigned to a product lot coming from an unique agricultural parcel (simple geoidentifier), it is also possible to design a geoidentifier for a product lot coming from several parcels in the same region (compound geoidentifier). The latter is an aggregation of simple geoidentifiers for product lots from individual parcels.

3.4. The notion of geoindicator

31Like any traceability system, within a geotraceability system there is no need to transmit or to have access to all the information relating to a production plot and its environmental context all along the food chain. Only the information that are relevant and usable by the different operators in the agri-food chain at a given time and place needs to be used. In geotraceability, the development of specific indicators offers a way to round this constraint.

32An indicator is defined as a quantitative or qualitative parameter that provides an overall description of the state of the environment or of a product. In order to be usable, it must meet a number of criteria, such as the scientific and statistical quality of the data used in calculating it, the availability and accessibility of those data and its relevance to the subject concerned and the needs of the potential users (Maurizi et al., 2002). An indicator can be used for the purposes of inspection (e.g. allowing to sort out products that do not match a certain quality level) and also for management of the farm or the agricultural environment, notably when integrated into a performance indicator relating, for instance, to compliance with agri-environmental measures.

33The adaptation of the notion of indicator to the context of geotraceability lends the latter a new dimension. A geoindicator is in fact defined as a parameter derived from processing spatial and temporal data that can describe the agri-environmental context of a production “parcel” or plot.

34In other words, it enables (Figure 3) what happens inside a parcel to be described (e.g. the history of fertilizer or plant protection product applications, or the characteristics of the soil), as well as supplying information about the impact of the parcel on its environment (e.g. surrounding parcels) or the impact of the environment on the parcel (e.g. the distance from a pollution source).

35The spatial nature of a geoindicator may be explicit, when it involves a model that explicitly takes into account the coordinates (x, y) and uses spatial information management algorithms. The indicator can only then be calculated with the aid of a GIS. Its spatial nature may be implicit if it involves data connected with geographical objects but it can be calculated without a GIS software; the latter then serves as a simple visualization tool.

36The definition of a geoindicator must take account of consumers’ expectations, the specific requirements of the operators in the supply chain and the regulatory requirements applying to the whole of the production chain. Geoindicators may relate to several themes, such as food safety, product quality (organoleptic quality and technological quality), the quality of the environment and also social issues (sustainable production methods). Geoindicators also contain a temporal dimension, to enable the traceability system to manage history for which the notion of time is of primordial importance.

37The data needed to cover these various themes can be classified into a number of categories, according to their sources or kind:

38– Data on agricultural practices (parcels of the farm, crop management, etc.);

39– Environmental data (agrometeorological, topographical and pedological data, satellite or aerial images, etc.);

40– Data on the surroundings, i.e. the immediate environment of the parcel (hedges, wooded areas, water resources, road network, etc.);

41– Data on events likely to affect parcels (location of a pollution source, etc.).

3.5. Characteristics of a geotraceability system

42Whatever its structure, a traceability system refers to the management of an information flow circulating permanently among the operators of an agri-food chain. A food traceability system is generally based on four pillars (Regattieri et al., 2007): product identification, data to trace, product routing and traceability tools. To ensure an efficient circulation of the information between agri-food chain actors, any traceability system must define a minimum data set (Anon., 2001; vanDorp, 2004) that local traceability systems have to exchange on the basis of international communications standards such as the GS1 system (www.gs1.org), which is widely used in supply chains. All along the agri-food chain, traceability data are linked to the product lots in the form of logistical identifiers which provide the necessary and essential information on the logistical units (box, pallet, etc.) to which they are affixed to enable them to be identified, tracked and managed in space and time. Such data are often private/internal and only accessible to a limited number of operators.

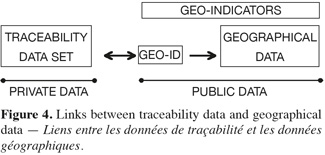

43As illustrated in figure 4, a geotraceability system should be regarded as an external module, supplementary to a conventional traceability system, to which spatial information (i.e. geoidentifier and geoindicators) are linked. In contrast to traceability data that remain the property of an operator or a supply chain, geographical data are public data and can be made accessible to internal or external users of the traceability system. According to the requirements of the traceability system, the chain carries downstream a set of private data that are specific to traceability (traceability data set). Public data, on the other hand, are accessible and available to both internal operators in a supply chain and external operators.

44However, adding geographical information to a traceability system means using appropriate techniques and tools for this type of information. It also requires cooperation models agreements to be defined between traceability systems and providers of geographical data as well as the development of dedicated tools to access and to analyze these information via remote connexions over the Internet.

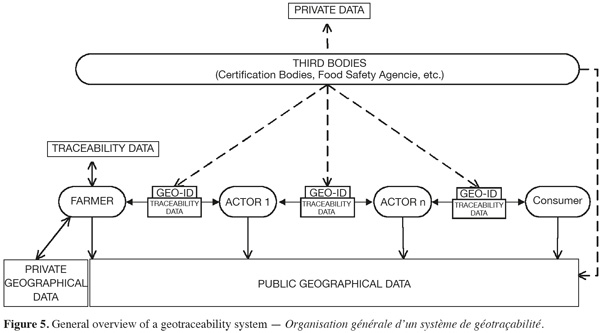

45Figure 5 represents a synthetic overview of a geotraceability system in which all the operators are interlinked, from the producer to the consumer. In this diagram, all the operators of the system are shown in oval boxes, while traceability data are in rectangular boxes and traceability data flows are indicated by arrows. External operators such as Certification Bodies or Food Safety Agencies represent independent third bodies which are not directly involved in the traceability chain but which can for example retrieve information from the system to set up food safety control plans or to verify the compliance with specifications such as geographical indications of origin. To these basic components is added a geoidentifier that enables private data (traceability data) to be linked to public geographical data (parcel limits, satellite images, etc). The geoidentifier also allows geotraceability indicators to be calculated at any moment by operators, without necessarily having access to traceability data or to parcel limits.

46Data flows are represented by arrows, with the direction indicating the type of processing: an outgoing arrow indicates consultation; an incoming arrow denotes a record. The arrows shown as solid lines are mandatory, systematic flows, whereas the arrows shown as dotted lines represent flows that only occur when necessary (for example, in the case of control or certification)

47This diagram reveals the potential uses of geotraceability systems within supply chains, in particular for raising the alarm in cases of food crisis and as support for certification and control of differentiated agricultural products.

48As a warning system, it enables the food safety authorities and the operators in the supply chain to:

49– identify easily the product lots grown on agricultural plots that are declared contaminated or unfit;

50– determine whether a product lot comes from plots that have been declared contaminated or unfit for agriculture.

51As a certification and control system for differentiated agricultural production, geotraceability system enables:

52– certification bodies to validate the stages of production covered by specific specifications (organic farming, integrated crop management, European Protected Designation of Origin, etc.);

53– control authorities to verify compliance with specific rules associated with the granting of public subsidies (for example, assessment of compliance with the conditionality rules of Common Agricultural Policy).

54The geotraceability system can also be used for marketing purposes, to promote products from a particular region or local area. For example, by making it possible for consumers to check the characteristics of the production conditions (soil type, environmental characteristics, etc.) of the food they buy.

4. Discussion and conclusion

55As it has been shown in this article, a geotraceability system can manage geographical information for the purpose of characterizing a lot of agricultural products by using a geoidentifier to locate and characterize the production unit (parcel, plot, etc.) geographically while characterizing the agri-environmental context using geoindicators. A geotraceability system is complementary to the existing traceability systems used in the various agricultural sectors.

56Geotraceability can be a response to the new issues and objectives of agriculture and it can fulfil consumers’ new expectations. This concept can be usefully applied in many areas, such as product certification, thereby giving added value to agricultural products (e.g. in case of European products coming from Protected Designation of Origin areas or growing in accordance with specific production standards, such as organic farming or integrated crop management). Geotraceability can also be used in the implementation of agricultural decision support systems (e.g. choice of production area) or crisis warning and management systems (e.g. withdrawal of products from the food chain). By improving the visibility of information, geotraceability can encourage consumers and other operators to develop a closer relationship with the food they buy.

57In complex traceability agri-food chains, geotraceability can also play a useful role by providing operators with more comprehensible information. Finally, geotraceability can help to limit the passing on of false and misleading information to consumers.

58However, to be fully operational, different sources of information on the direct and indirect environment of agricultural parcels must in fact be available and easily accessible. That implies the setting up of specific access to geo-portals offering Web services to meet the potential users needs. It is therefore a priority to focus the efforts of collecting, harmonizing, updating and making available public spatial data resources. Fortunately, there are many on going initiatives in this direction, one good example being the European INSPIRE initiative and directive.

59Originally developed for the plant sector, the geotraceability concept can be transferred (with a few adaptations) to the animal sector insofar as animal products are connected with environmental characteristics. A “lot” of animals can be assimilated to a “lot” of plant products to be traced all over the agri-food chain until the consumer. In this case the products concern meat and dairy products. It is recognized that the quality of such products is closely linked with the quality of the animal feed and, in particular, the quality of the forage and pasture land. These plant products are in turn linked to the agri-environmental context of the production area. As with plant products, the geotraceability concept can be used in a crisis to facilitate withdrawal of products from contaminated production areas or, on the other hand, to give products added value.

60Acknowledgements

61The authors wish to acknowledge the financial assistance of the European Commission through the FP5/IST project GeoTraceAgri and the FP6/SSA project GTIS-CAP led by the Chamber of Commerce and Industry of the Gers region (France).

Bibliographie

Anon., 2001. La traçabilité dans les chaines d’approvisionnement : de la stratégie à la pratique. Issy-Moulineaux, France : GS1 France Ed.

Anon., 2002. Les Européens et la politique agricole commune. European Opinion Research Group.

Boisvert I., Kolm C., Sans E.M. & Turinek Ytting N.K., 2005. Community supported agriculture in Denmark: promoting organic ideals through local food links, KVL-Ecological Agriculture, http://www.kursus.kvl.dk/shares/ea/03Projects/32gamle/_2005/CSA%20in%20Denmark.pdf, (18.04.08).

Bonizzi I., Feligini M., Aleandri R. & Enne G., 2007. Genetic traceability of the geographical origin of typical Italian water buffalo Mozzarella cheese: a preliminary approach. J. Appl. Microbiol., 102, 667-673.

Debord M. et al., 2005. Geotraceability: an innovative concept for the qualification of crop production. Auch, France: Chamber of Commerce and Industry of the Gers region.

European Standard, 1995. European Commitee for Standardization (CEN), EN ISO 8402:1995, Point 3.16.

Franke B.M., Gremaud G., Hadorn R. & Kreuzer M., 2005. Geographic origin of meat. Elements of an analytical approach to its authentication. Eur. Food Res. Technol., 221, 493-503.

Franke B.M. et al., 2008. Tracing the geographic origin of poultry meat and dried beef with oxygen and strontium isotope ratios. Eur. Food Res. Technol., 226, 761-769.

Golan E. et al., 2004. Traceability in the U.S. food supply: economic theory and industry studies. Agricultural Economic Report 830. Washington, DC, USA: U.S. Department of Agriculture (USDA).

Hobbs J., 2004. Liability and traceability in agri-food supply chains. In: Proceedings of the Frontis workshop on quantifying the agri-food supply chain, 22-24 October 2004, Wageningen, The Netherlands.

ISO 8402, 1994. Quality management and quality assurance. Vocabulary. Geneva, Switzerland: International Organization for Standardization.

ISO 22000, 2005. Food safety management systems. Requirements for any organization in the food chain. Geneva, Switzerland: International Organization for Standardization.

ISO 22005, 2005. Traceability in feed and food chain. General principles and basic requirements for system design and implementation. Geneva, Switzerland: International Organization for Standardization.

Mauriello G., Moio L., Genovese A. & Ercolini D., 2003. Relationships between flavoring capabilities, bacterial composition, and geographical origin of natural whey cultures used for traditional water-buffalo Mozzarella cheese manufacture. J. Dairy Sci., 86, 486-497.

Maurizi B. & Verrel J.L., 2002. Des indicateurs pour les actions de maîtrise des pollutions d’origine agricole. Ingénieries, 30, 37-48.

Moe T., 1998. Perspectives on traceability in food manufacture. Trends Food Sci. & Technol., 9, 211-214.

Nanseki T. & Yokoyama K., 2008. Improving food safety amongst food operators. In: Smith I.G. & Furness A. Food Traceability around the world. Vol. 1. Halifax, UK: Vicarage Publications Ltd., 46-65.

Pillonel L., Ampuero S., Tabacchi R. & Bosset J.O., 2003. Analytical methods for the determination of the geographic origin of Emmental cheese: volatile compounds by GC/MS-FID and electronic nose. Eur. Food Res. Technol., 216, 179-183.

Prache S., Cornu A., Berdague J. & Priolo A., 2005. Traceability of animal feeding diet in the meat and milk of small ruminants. Small Ruminant Res., 59, 157-168.

Regattieri A., Gamberi M. & Manzini R., 2007. Traceability of foods products: general framework and experimental evidence. J. Food Eng., 81, 346-356.

Regulation (EC) n°178/2002 of the European Parliament and of the Council laying down the general principles and requirements of food law, establishing the European Food Safety Authority and laying down procedures in matters of food safety. Off. J. Eur. Communities, L31, 01.02.02, 1.

Schwägele F., 2005. Traceability from a European perspective. Meat Sci., 271, 164-173.

Suhaj M. & Korenovska M., 2008. Study of some European cheeses geographical traceability by pattern recognition analysis of multielemental data. Eur. Food Res. Technol., 1, 101-106.

vanDorp C., 2004. Reference-data modelling for tracking and tracing. Wageningen, The Netherlands: Wageningen University.

Zunin P., Boggia R., Salvadeo P. & Evangelisti F., 2005. Geographical traceability of West Liguria extravirgin olive oils by the analysis of volatile terpenoid hydrocarbons. J. Chromatogr. A, 1089, 243-249.

Para citar este artículo

Acerca de: Robert Oger

Centre wallon de Recherches agronomiques (CRA-W). Unité Systèmes agraires, Territoire et Technologies de l'Information. Rue de Liroux, 9. B-5030 Gembloux (Belgium). E-mail: oger@cra.wallonie.be

Acerca de: Alain Krafft

Centre wallon de Recherches agronomiques (CRA-W). Unité Systèmes agraires, Territoire et Technologies de l'Information. Rue de Liroux, 9. B-5030 Gembloux (Belgium).

Acerca de: Dominique Buffet

Centre wallon de Recherches agronomiques (CRA-W). Unité Systèmes agraires, Territoire et Technologies de l'Information. Rue de Liroux, 9. B-5030 Gembloux (Belgium).

Acerca de: Michel Debord

Chambre de Commerce et d'Industries d'Auch et du Gers. Maison du Commerce et de l'Industrie. Place Jean David. BP 181. F - 32004 Auch (France).