- Portada

- Volume 14 (2010)

- numéro 4

- Energy use and economic analysis of strawberry production in Sanandaj zone of Iran

Vista(s): 0 (0 ULiège)

Descargar(s): 0 (0 ULiège)

Energy use and economic analysis of strawberry production in Sanandaj zone of Iran

Notes de la rédaction

Received on January 19, 2010; accepted on May 18, 2010

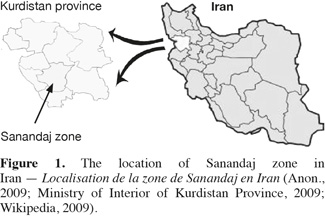

Résumé

Consommation d'énergie et analyse économique de la production de fraises dans la zone de Sanandaj en Iran. L’objectif de cette étude était de déterminer la consommation d’énergie et de réaliser l’analyse économique de la production de fraises. Les données ont été recueillies auprès de 60 agriculteurs qui cultivent des fraises dans la zone de Sanandaj en Iran, en utilisant un questionnaire de type face-à-face en aout-septembre 2009. Le labour dans la zone d’étude a été effectué par deux méthodes : manuellement (P1) et par machine (P2). Deux méthodes d’irrigation ont également été utilisées : avec pompage (P) et sans pompage (NP). L’analyse de la variance univariée a été utilisée pour mettre en évidence des différences significatives à 5 % et à 1 % liées aux facteurs labour et irrigation sur l’énergie totale utilisée pour la production et sur la rentabilité de la culture. L’énergie totale utilisée dans les exploitations agricoles pour la production de fraises a été de 53 605 MJ.ha-1. La production totale d’énergie a été de 17 338 MJ.ha-1 et le rendement annuel moyen de fraises a été de 9 125 kg.ha-1. L’efficacité énergétique a été de 0,32 et la productivité énergétique calculée de 0,17 kg.MJ-1. Cela signifie que la production de fraises obtenue par unité d’énergie est de 0,17 kg. La différence entre l’apport total d’énergie dans les types d’irrigation (NP et P) est significative au seuil de 1 %. Il n’y a pas de différence significative entre les modes de labour. L’interaction entre les facteurs irrigation et labour est significative au seuil de 5 %. Le ratio couts-bénéfices, la productivité et le résultat net pour la production de fraises sont de 1,2 ; 0,99 et 1 825 $.ha-1, respectivement. La différence entre le rendement net dans les différents types d’irrigation (NP et P) est significative au seuil de 5 %. La différence entre le rendement net dans les différents types de labour (P1 et P2) est significative au seuil de 1 %.

Abstract

The aim of this study was to determine the energy consumption and economic analysis for strawberry production. The data were collected from 60 farmers growing strawberry in the Sanandaj zone of Iran by using a face-to-face questionnaire in August-September 2009. The plowing operation at the study area was done by two methods; manually plow (P1) and machinery plow (P2). Also the irrigation operation was done by two methods; pumping irrigation (P) and non pumping irrigation (NP). Univariate analysis of variance was used for finding the differences among the total energy used for production and profitability of this crop in the different methods at the 5% and 1% level. Total energy used in various farm operations during strawberry production was 53,605 MJ.ha-1. Total energy output was 17,338 MJ.ha-1, and the average annual yield of strawberry farms was 9,125 kg.ha-1. Energy efficiency was 0.32, and energy productivity calculated as 0.17 kg.MJ-1. This means a production of 0.17 kg per unit energy. The difference between total input energy in the different irrigation types (NP and P) is significant at 1% level. There is not any significant difference between different plow types at the 5% level. The interaction of irrigation types and plow types is significant at 5% level. The profit-cost ratio, productivity, and net profit in the strawberry production are 1.2, 0.99, and 1,825 $.ha-1, respectively. The difference between net return in the different irrigation types (NP and P) is significant at 5% level. The difference between net return in the different plow types (P1 and P2) is significant at 1% level.

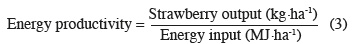

Tabla de contenidos

1. Introduction

1Attractive and flavorful, the strawberry is also nutritious. A cup of strawberries will supply more than the recommended human daily requirement of vitamin C with only 55 calories. A bed of 25-50 strawberry plants will produce enough berries for an average-sized family (Dickerson, 2004).

2Strawberry is an important small fruit, grown throughout the world. It is deep red in color with unique shape and flavor. The major strawberry producing countries of the world are USA, Spain, Japan, Poland, Korea and Russian Federation. The estimated production of strawberries in the world during 2007 was 5,822 thousand tons (Sharma et al., 2009).

3Strawberry (Fragaria × ananassa Duchesne) fruits are popularly consumed in fresh forms, as processed food products, and as botanical extracts for dietary supplements. Strawberries have high antioxidant activity, which has been linked to their content of phenolic compounds. Strawberry juice extracts exhibit high levels of antioxidant capacity against superoxide radicals, hydrogen peroxide, hydroxyl radicals, and singlet oxygen free radicals. The contents of phenolics in strawberries have been associated with the total antioxidant capacity for low-density lipoproteins of the fruit extracts (Zhang et al., 2008).

4In developing countries like Iran, agricultural growth is essential for fostering the economic development and meeting the ever-higher demands of the growing population. Energy in agriculture is important in terms of crop production and agro processing for value adding (Karimi et al., 2008).

5Energy use in agriculture has been developed in response to increasing populations, limited supply of arable land and desire for an increasing standard of living. In all societies, these factors have encouraged an increase in energy inputs to maximize yields, minimize labor-intensive practices or both (Esengun et al., 2007).

6In agriculture, a wide range of modern and traditional energy forms are used directly on the farm, e.g. as tractor or machinery fuel, and in water pumping, irrigation and crop drying, and indirectly for fertilizers and pesticides. Other energy inputs are required for post harvest processing in food production, packaging, storage, transportation and cooking (FAO, 2000).

7Energy productivity is an important index for more efficient use of energy although higher energy productivity does not mean in general, more economic feasibility. However, the energy analysis shows the methods to minimize the energy inputs and therefore to increase the energy productivity (Fluck et al., 1982).

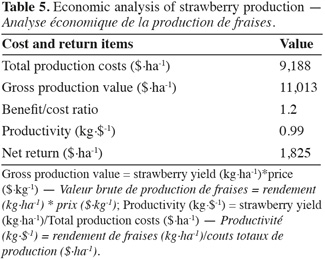

8Calculating energy inputs of agricultural production is more difficult than in the industry sector due to the high number of factors affecting the production (Yaldiz et al., 1993).

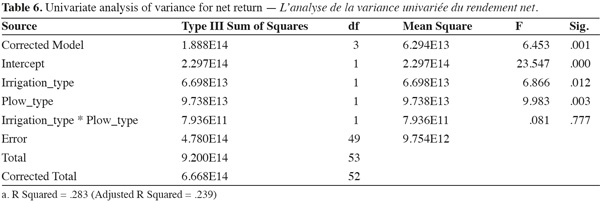

2. Materials and methods

2.1. Location and period of the study

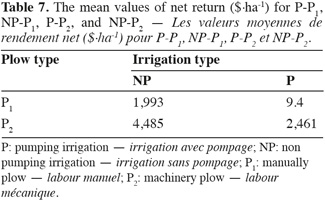

9The data were collected from 60 farmers growing strawberry in Sanandaj zone by using a face-to-face questionnaire in August-September 2009. This zone is located in Kurdistan province of Iran. The location of Sanandaj zone in Iran is shown in figure 1.

2.2. Sample size

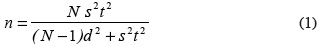

10As it is shown in Eq. 1, the sample size was determined by using the simple random sampling method (Salami et al., 2009).

11in which n is the required sample size, s is the standard deviation, t is the t value at 95% confidence limit (1.96), N is the number of holdings in target population and d is the acceptable error. The standard deviation of the energy efficiency was determined as 0.10298 from a primary collected sample (30 samples). The number of holdings in target population (N) was 7,000. The acceptable error (d) was 3%. So the sample size was determined as 45. For improving the accuracy, 60 samples were collected. In this situation d is 2.6%.

2.3. Energy equivalents of used inputs

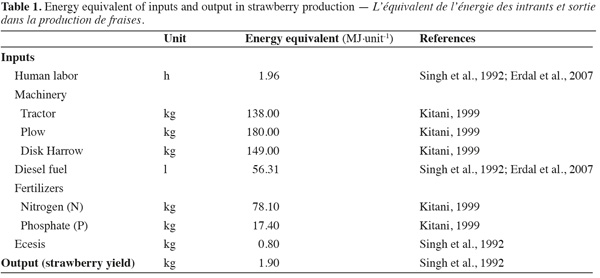

12The energy efficiency of the agricultural system has been evaluated by the energy ratio between output and input. Human labor, machinery, diesel oil, fertilizer, and ecesis amounts and output yield values of strawberry crops have been used to estimate the energy ratio. The amounts of input were calculated per hectare and then, these input data were multiplied with the coefficient of energy equivalent given in table 1.

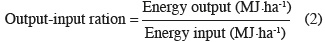

13Basic information on energy inputs and strawberry yields were entered into Excel and SPSS 17 spreadsheets. The energy ratio (energy use efficiency) and energy productivity were calculated, as they are shown in Eq. 2 and Eq. 3 (Singh et al., 1997; Mandal et al., 2002):

14The plowing operation at the study area was done by two methods. At the first method it was done manually by the workers (P1 method), while at the second method it was done by agricultural machinery (P2 method). Also the irrigation operation was done by two methods. In some places there was a river or spring water that the farmers used without using any energy for pumping the water. This was non pumping irrigation method (NP method). In other fields there was not such a source and the farmers pumped the water from a well or a river in a lower altitude. This was pumping irrigation method (P method). The differences among the total energy used for production and profitability of this crop for the two levels of the two factors were investigated by univariate analysis of variance at the 5% and 1% significance level.

3. Results and discussion

3.1. Analysis of input-output energy use in strawberry production

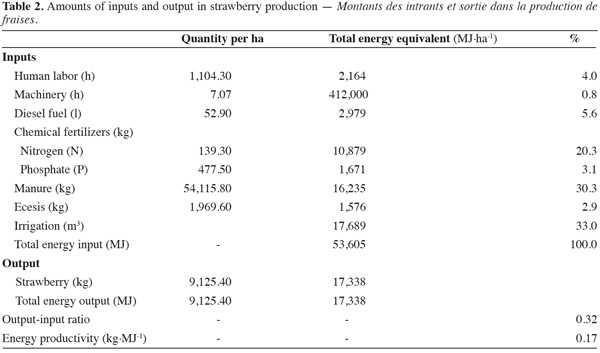

15Used inputs in the strawberry production, energy equivalences, and ratio of inputs and output are illustrated in table 2. Total energy used in various farm operations during strawberry production was 53,605 MJ.ha-1.

16The most of the agricultural operations was done manually in the study area, while using the agricultural machinery was limited to some areas and only for land preparation. According to the evaluation of data in table 2, the average human labor required in the study area was 1,104.3 h.ha-1, and machine power was just 7.07 h.ha-1.

17Total energy consumed in various farm operations during strawberry production was 53,605 MJ.ha-1. Irrigation energy consumed 33% of total energy followed by manure (30%) during production period. Machinery was the least demanding energy input for strawberry production with 412 MJ.ha-1 (only 0.8% of the total energy input), followed by ecesis with 1,576 MJ.ha-1 (2.9%). Total energy output was 17,338 MJ.ha-1, and the average annual yield of strawberry farms was 9,125.4 kg.ha-1.

18Energy output-input ratio (energy efficiency) in this study was 0.32, and energy productivity calculated as 0.17 kg.MJ-1. This means that 0.17 kg of strawberry were obtained per unit of energy.

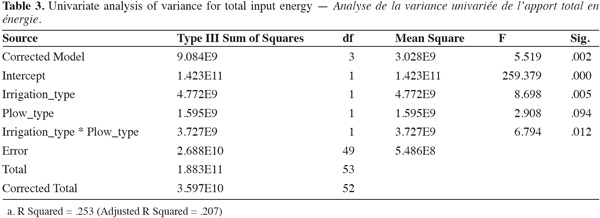

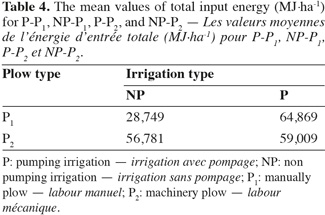

19As it is obvious from the analysis of variance (Table 3), the difference between total input energy in the different irrigation types (NP and P) is significant at 1% level. The total input energy used in the second type of irrigation (P) was higher than the other irrigation type (NP) (Table 4). This result is acceptable, because NP method did not use any energy for performing irrigation operation, while P method used a pump for performing irrigation operation. In the most cases an electromotor pump and in some cases a diesel pump were used for pumping the water in the P method.

20Also it is obvious that there is not any significant difference between different plow types at the 5% level. This result is acceptable; notwithstanding P1 method did not use any machinery energy for performing plowing operation, at the P2 method the agricultural machinery was used only for land preparation and the amount of energy used was not significantly higher than P1 method at the 5% level, but the interaction of irrigation types and plow types is significant at 5% level.

21Table 4, that gives the mean values of total input energy for P-P1, NP-P1, P-P2, and NP-P2 shows that the least total input energy was 28,749 MJ.ha-1 for NP-P1 and the highest total input energy was 64,869 MJ.ha-1 for P-P1.

3.2. Economic analysis of strawberry production

22The economic analysis is presented in table 5. The profit/cost ratio, productivity, and net profit in the strawberry production were 1.2, 0.99, and 1,825 $.ha-1, respectively.

23As it is obvious from the analysis of variance (Table 6), the difference between net return in the different irrigation types (NP and P) is significant at 5% level. The net return in the first type of irrigation (NP) is significantly higher than in the other irrigation type (P) (Table 7). This result is acceptable, because there was not any cost for production in the NP method for irrigation operation, while acquiring water in the P method required some cost (electricity or diesel cost).

24Also it is obvious that the difference between net return in the different plow types (P1 and P2) is significant at 1% level. The net return in the second plow type (P2) is higher than the other plow type (P1). This result is acceptable; because as the plowing operation at the P1 method was manually, it took a lot of labor cost and time, while the plowing operation at the P2 method was done by agricultural machinery, so the plowing cost at this method (P2) was much lower that the other type.

25Table 7, that gives the mean values of net return for P-P1, NP-P1, P-P2, and NP-P2 shows that the least net return was 9.4 $.ha-1 for P-P1 and the highest net return was 4,485 $.ha-1 for NP-P2. The net return for P-P1 was too low. That is because of high labor wages for land preparation and also high energy costs for irrigation. Thus it is not commodious to produce strawberry in this category (P-P1) and the most profitable category is NP-P2.

4. Conclusion

26At this study, the total energy used was 53,605 MJ.ha-1 in various farm operations during strawberry production. The average annual yield of strawberry farms was 9,125.4 kg.ha-1, and total energy output was 17,338 MJ.ha-1. Energy productivity calculated as 0.17 kg.MJ-1, and energy efficiency was 0.32. The benefit-cost ratio, productivity, and net profit in the strawberry production were 1.2, 0.99, and 1,825 $.ha-1, respectively.

Bibliographie

Anon., 2009. http://ir.mihanblog.com/post/137.

Dickerson G.W., 2004. Home garden strawberry production in new Mexico, http://aces.nmsu.edu/pubs/_h/h-324.pdf, (01/10/10).

Erdal G., Esengün K., Erdal H. & Gündüz O., 2007. Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy, 32, 35-41.

Esengun K., Gündüz O. & Erdal G., 2007. Input-output energy analysis in dry apricot production of Turkey. Energy Convers. Manage., 48, 592-598.

FAO, 2000. The energy and agriculture nexus. Environment and natural resources working paper n°4. Roma: FAO.

Fluck R.C. & Baird C.D., 1982. Agricultural energetics. Westport, CT, USA: AVI Publications, 41-45, 51-54, 71-72, 123-126.

Karimi M., Beheshti Tabar I. & Khubbakht G.M., 2008. Energy production in Iran’s agronomy. Am. Eurasian J. Agric. Environ. Sci., 4(2), 172-177.

Kitani O., 1999. Energy and biomass engineering. CIGR handbook of agricultural engineering. Vol. 5. St. Joseph, MI, USA: ASAE Publication.

Mandal K.G. et al., 2002. Bioenergy and economic analysis of soybean-based crop production systems in Central India. Biomass Bioenergy, 23(5), 337-345.

Ministry of Interior of Kurdistan Province, 2009. Kurdistan Province, http://en.ostan-kd.ir/Default.aspx?TabID=51, (01/10/10).

Salami P., Keyhani A. & Rafiee Sh., 2009. The impact of farm size on energy use and profitability of red bean production in Iran: a case study in Kurdistan province. Nature Sci., 7(9), 95-104, http://www.sciencepub.net/nature/0709/16_1139_Salami_Payman_ns0709.pdf, (01/10/10).

Sharma S., Joshi V.K. & Abrol Gh., 2009. An overview on strawberry [Fragaria x ananassa (Weston) Duchesne ex Rozier] wine production technology, composition, maturation and quality evaluation. Nat. Prod. Radiance, 8(4), 356-365.

Singh M.K., Pal S.K., Thakur R. & Verma U.N., 1997. Energy input-output relationship of cropping systems. Indian J. Agric. Sci., 67(6), 262-266.

Singh S. & Mittal J.P., 1992. Energy in production agriculture. New Delhi: Mittal Pub.

Wikipedia, 2009. Kurdistan Province, http://en.wikipedia.org/wiki/Kurdistan_Province, (01/10/10).

Yaldiz O., Ozturk H.H., Zeren Y. & Bascetomcelik A., 1993. Energy usage in production of field crops in Turkey. In: Fifth international congress on mechanization and energy use in agriculture, 11-14 October 1993, Kusadasi, Turkey.

Zhang Y. et al., 2008. Isolation and identification of strawberry phenolics with antioxidant and human cancer cell antiproliferative properties. J. Agric. Food Chem., 56, 670-675.

Para citar este artículo

Acerca de: Payman Salami

University of Tehran. Faculty of Agricultural Engineering and Technology. Department of Agricultural Machinery Engineering. P.O. Box 4111. IR-Karaj 31587-77871 (Iran). E-mail: payman.salami@gmail.com

Acerca de: Hojat Ahmadi

University of Tehran. Faculty of Agricultural Engineering and Technology. Department of Agricultural Machinery Engineering. P.O. Box 4111. IR-Karaj 31587-77871 (Iran).

Acerca de: Alireza Keyhani

University of Tehran. Faculty of Agricultural Engineering and Technology. Department of Agricultural Machinery Engineering. P.O. Box 4111. IR-Karaj 31587-77871 (Iran).