Cotton plant topping combined with plant density has a positive effect on seed-cotton yield in the South Sudanian zone of Mali

Résumé

L’écimage du plant de coton, en combinaison avec la densité végétale, a un effet positif sur le rendement des semences de coton dans la zone sud soudanienne au Mali

Description du sujet. Au Mali, le coton (Gossypium hirsutum L.) est la principale culture de rente, aux côtés des cultures vivrières essentiellement destinées à l’autoconsommation et à la mise au marché du surplus. L'écimage du cotonnier est une technique culturale qui permet de réduire la croissance en taille du cotonnier tout en favorisant le processus d’élaboration de la production.

Objectifs. L'étude visait à évaluer l’effet de l’écimage associé à différentes densités de semis sur le rendement du cotonnier.

Méthode. L'étude a été menée pendant deux ans (2020 et 2021) à la station de recherche de Finkolo en zone soudanienne du Mali et une année (2022) en milieu réel. L'expérience comprenait deux variétés de coton (NTAMS334 et BRS293) et quatre modalités de semis avec ou sans écimage. La densité de semis recommandée de 80 cm x 30 cm avec deux plants par trou de semis a été comparée à une nouvelle densité de semis de 80 cm x 20 cm avec un plant par trou de semis. Le principal avantage de la nouvelle densité de semis était l’accélération de la croissance en hauteur de la plante de coton grâce à la forte concurrence pour la lumière avant le rempotage.

Résultats. Les résultats montrent que la pratique de l'écimage a réduit de manière significative le nombre moyen de branches fructifères par plant (14 pour les modalités non écimées et 10 pour les modalités écimées). Par ailleurs, le nombre de positions fructifères occupées par plant, la charge capsulaire par plant et le rendement coton graine ont augmenté avec les modalités écimées. Le rendement coton graine le plus élevé en station (2 238 kg·ha-1) et en milieu paysan (2 391 kg·ha-1) a été obtenu avec les nouvelles densité et géométrie de semis associées à l’écimage.

Conclusions. Les résultats de la présente étude peuvent être utilisés en tant que modificateur de la canopée et de la géométrie de semis dans des conditions de croissance excessive du cotonnier.

Abstract

Description of the subject. In Mali, cotton (Gossypium hirsutum L.) plays an essential role in economic and social activities in terms of income generation, rural organization and modernization of production systems. Cotton topping is a cultivation technique that reduces the growth in size of the cotton plant while favoring the production process.

Objectives. The aim of this study was to evaluate the effect of topping combined with new sowing density on seed-cotton yield.

Method. The study was conducted in Mali over two years (2020 and 2021) at the Finkolo research station in the Sudanian zone and one year (2022) in farmers’ fields. The experiment included two cotton varieties (NTAMS334 and BRS293) and two sowing densities, with or without topping cotton plants. The recommended sowing density of 80 cm x 30 cm with two plants per seed hole was compared with a new sowing density of 80 cm x 20 cm with one plant per seed hole. The main advantage of the new sowing density was the acceleration of the cotton plant's growth in height, thanks to the strong competition for light before topping.

Results. The results showed that topping significantly reduced the average number of fruit-bearing branches per cotton plant (14 for the non-topped modalities and 10 for the topped modalities). The number of fruiting positions occupied per plant, boll load per plant, and seed-cotton yield increased with topping. The highest seed-cotton yields at the research station (2,238 kg·ha-1) and in farmers’ fields (2,391 kg·ha-1) were obtained with the new sowing density combined with topping.

Conclusions. The results of this study can be used as a modifier of canopy and sowing density under cotton overgrowth conditions.

Received 28 April 2024, accepted 26 November 2024, available online 16 December 2024.

This article is distributed under the terms and conditions of the CC-BY License (http://creativecommons.org/licenses/by/4.0)

1. Introduction

1The cotton sector plays an essential role in Mali’s economic and social activities in terms of job creation, rural organization, and the improvement of agricultural production systems (Soumaré & Havard, 2018). Cotton is grown on many small family farms, mainly in the south of the country. More than 4 million rural producers directly or indirectly depend on cotton revenues (Soumaré et al., 2019). The cotton sector’s contribution to the Gross Domestic Product (GDP) is 15% higher (Soumaré et al., 2019; CMDT, 2022). Cotton is used in textiles, animal feed, and oil for humans. Seed cotton is on average 55% seed, 40% fiber, and 5% waste (CNUCED, 2016). However, it is worrying to note that at the national level, the average seed-cotton yield per hectare, which was around 1,359 kg in 1990-1991, has fallen drastically in recent years. The average seed-cotton yield over the last decade is 923 kg·ha-1 (PR-PICA, 2022). The following causes are generally mentioned to explain this drop in yields:

2– irregular rainfall at the start of the rainy season and early cessation at the end of the season;

3– the busy cropping calendar and lack of manpower on farmers’side, who are unable to maintain crops at the optimum time;

4– the extension of crops onto marginal land;

5– the problem of soil loss through erosion;

6– the declining fertility of cultivated soils;

7– the resistance of pests to available insecticides.

8The effect of climate variability and change is also being felt through a drastic drop in seed-cotton yields (Diouf et al., 2017). Combining reasoned alternatives by studying the various constraints linked to yield reduction (plant productivity, cultivation practices and pest control) in suitable systems can help improve yields. Cotton topping is an ancient agricultural practice consisting in cutting the apex of the main stem after the first flowers have appeared. This practice has been proposed in this Malian context and could be of interest for its numerous advantages (Diarra et al., 2020), notably the reduction of vegetative exuberance (Obasi & Msaakpa, 2005), the limitation of lodging risks (Renou et al., 2011; Tereta, 2015), the improvement of production earliness (Obasi & Msaakpa, 2005; Traoré et al., 2017). Topping vegetative branches and the main stem in favor of fruiting branches reduces the cotton plant’s height growth in favor of lateral growth (Kumari & George, 2012). This reduction in height growth can also be achieved by modifying the density of cotton seedlings. Modification of cotton plants density, combined with topping of the main stem, increases the lateral growth of fruit-bearing branches and consequently favors boll development (Roy et al., 1989). Other studies associating topping with certain cultural practices such as sowing density have also demonstrated positive effects on yield (Ahmed et al., 1989; Obasi & Msaakpa, 2005; Traoré et al., 2017). Sowing density is a key factor in improving cotton productivity (Soomro et al., 2000; Yang et al., 2014). Very low or very high sowing densities can compromise crop yields (Ciampitti & Vyn, 2011). For example, Soomro et al. (2000) reported that 23 and 30 cm plant spacing recorded higher seed cotton yields than 15 and 38 cm spacing and recommended 20-30 cm plant spacing and 75 cm row spacing in Pakistan. Khan et al. (2005) reported a density of 100,000 plants per hectare as optimal with a row spacing of 76 cm. However, Jagannathan & Venkitaswamy (1996) reported a decrease in seed cotton yield with increasing seeding density, while other authors reported no relationship between seeding density and seed cotton yield (Muhammad et al., 2002; Akhtar et al., 2003). Also, cutting the terminal main stem bud (topping) and side pruning of branches are considered as important adjustments for geometry of cotton plants grown on fertile soils of high nitrogen rates (Obasi & Msaakpa, 2005). The technique also limits cotton lodging under conditions of high or low cotton stand density (Obasi & Msaakpa, 2005). Cotton topping offers other benefits, including reduced pest populations and improved fiber quality (Renou et al., 2011). If topping has advantages in terms of reducing the boll worm population and improving seed cotton yield, some technical constraints such as the topping period (El-Hanafi et al., 1982; Diarra et al., 2020) and the increase in farmers' workload (Diarra et al., 2020) are considered as limitations of the topping technique. The increase in seed-cotton production and the improvement in some of its components (number of fruiting positions, number of bolls, boll weight, etc.) appear much less regularly and are still insufficiently explained (Renou et al., 2011). One way to better explain the improvement in yield components is to describe the process of production development when cotton plant topping is combined with different sowing densities. In Mali, the popular cotton sowing density is 83,333 plants·ha-1 for a spacing of 80 cm between rows and 30 cm between plants on the row, with two plants per seed hole. Previous experiments studied separately the effects of cotton plant density (Lawson, 2008) or the effects of cotton topping (Obasi & Msaakpa, 2005) but, to our knowledge, none has studied the combined influence of these two factors. While plant density per unit area is a key factor in crop production, seedling spacing determines how plants occupy the unit area. In addition, topping the cotton plant provides good architecture so that the plant can receive the necessary sunlight with a minimum of mutual shading. Thus, the overall radiation received by the plant canopy is efficient and improves crop growth and development. In this study, the focus was on data from the Finkolo research station in Mali. These include:

9– describing the process of production development at the plant level as a function of sowing density and in relation to the performance of varieties when cotton plants are topped;

10– determining the best sowing density in relation to topping performance and cotton plant yield;

11– determining the effect of topping on the technological characteristics of cotton plant fiber in relation to sowing density.

12Second, to perform demonstration tests with farmers in seven villages involved in the AgrEco (Agriculture and Agro-Ecological Transition) project.

13The aim of this study was to assess the effect of topping combined with new sowing densities on seed-cotton yield.

2. Materials and methods

2.1. Study area

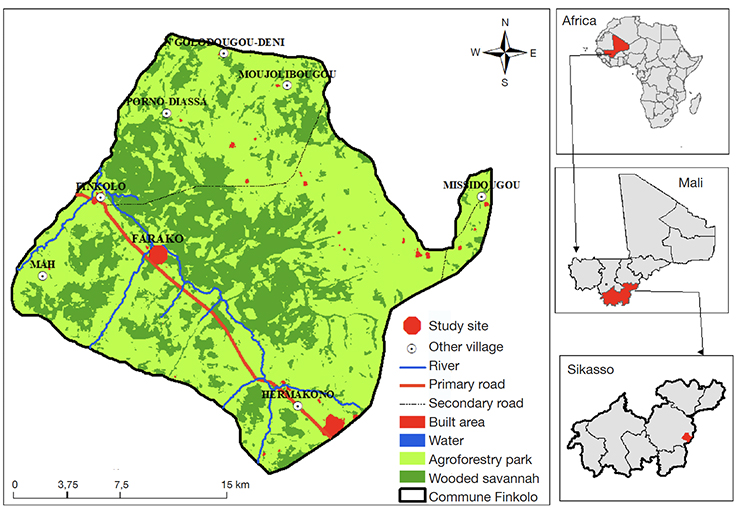

14The study was conducted in Finkolo area, Mali (Figure 1). It was carried out at the Finkolo agricultural research station in 2020 and 2021, as well as in cotton farmers' fields in several villages in the region in 2022. The bioclimatic zone is South Sudanian (PIRT, 1986).

Figure 1. Location of Finkolo agricultural research station — Localisation de la station de recherche agricole de Finkolo.

Source: ESRI, 2020.

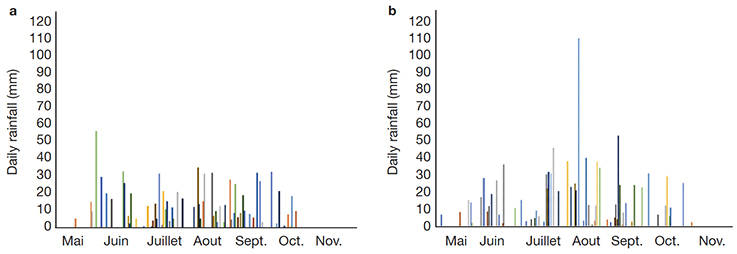

15According to Sissoko (2009), soil texture at the Finkolo agricultural research station is sandy loam to sandy loam on the surface with less than 10% clay, becoming silty clay at depth. The level of organic matter in the first 20 cm of soil is approximately 0.8%, decreasing slightly with depth to between 0.2% and 0.6%. The mineralization rate (C/N ratio) is between 10.27 and 15.74. The soil reaction is moderately acidic (5.5-5.8). Rainfall was higher in 2021 (1,253.8 mm in 67 rainy days) than in 2020 (930.4 mm in 64 rainy days). Figure 2 shows daily rainfall for the two experimental years. The average rainfall recorded at Finkolo during the study period was 1,092.1 mm over 66 rainy days.

Figure 2. a. Daily rainfall in 2020 in Finkolo; b. Daily rainfall in 2021 à Finkolo — a. Précipitations quotidiennes en 2020 à Fonkolo ; b. Précipitations quotidiennes en 2021 à Finkolo.

2.2. Experimental setup

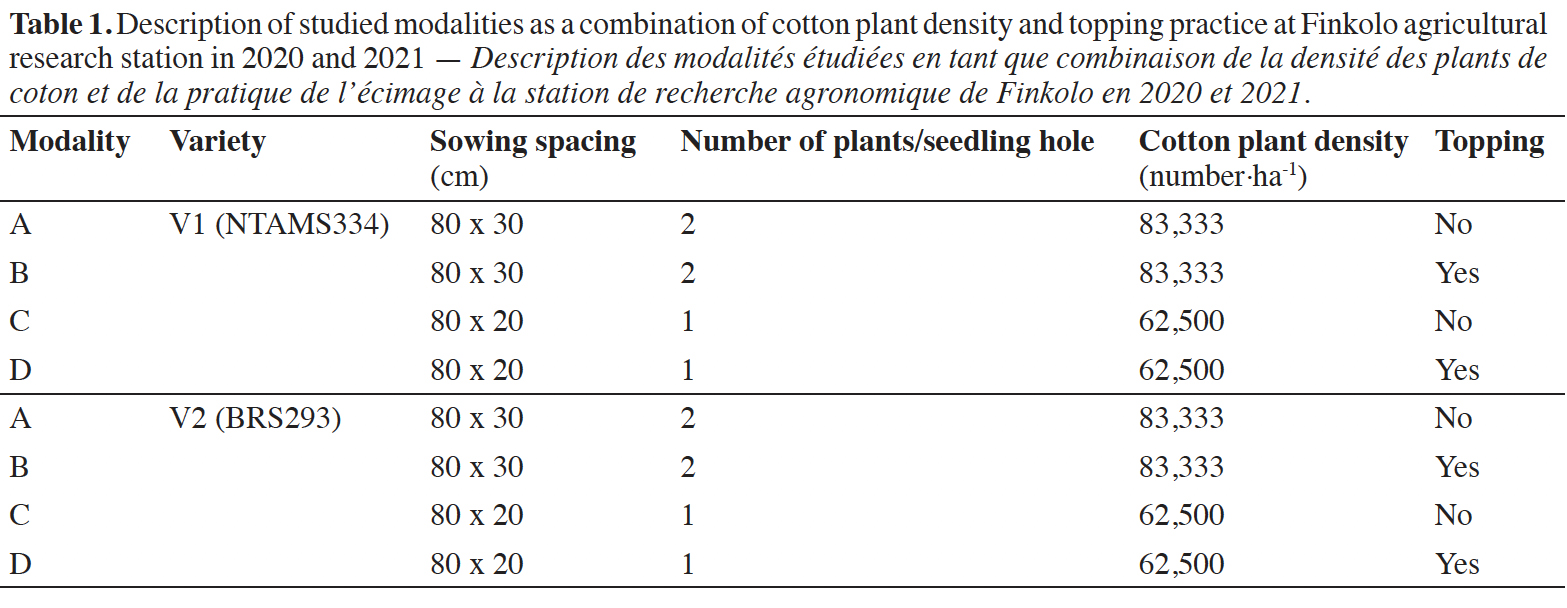

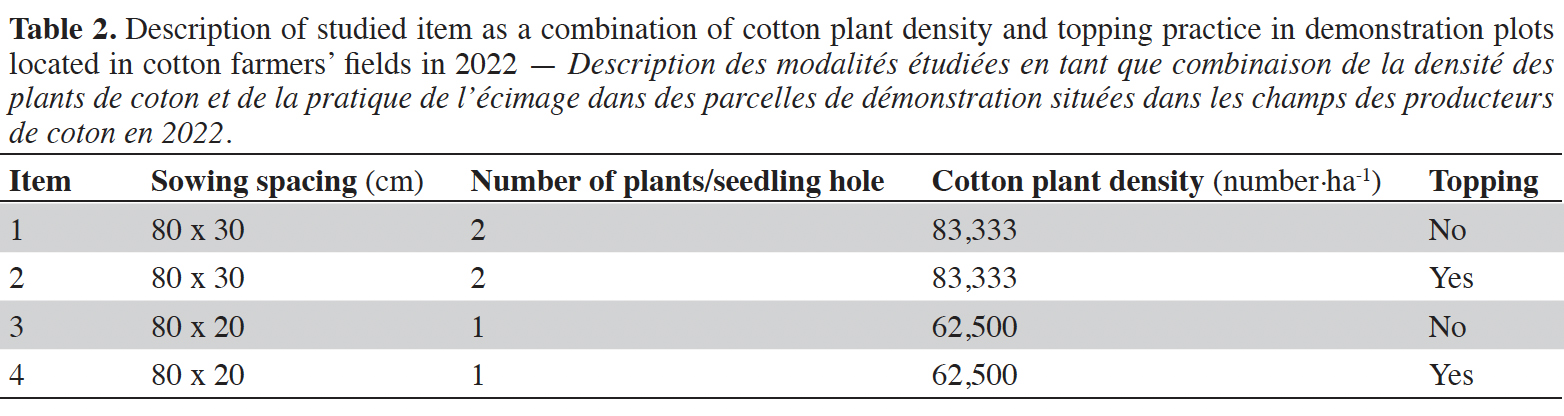

16At the Finkolo agricultural research station, the trial was set up in a factorial design with four replicates. The first factor related to the variety’s topping behavior and comprised two levels: V1 (NTAMS334 variety) and V2 (BRS293 variety), while the combination of sowing density and topping practice constituted the second factor and comprised four modalities (Table 1). Topping was carried out manually 65 days after sowing.

17The NTAMS334 variety is of Malian origin, characterized by its high plant height (129.6 cm) and a fiber length (Upper Half Mean Length, UHML) above the threshold required by the textile industry (28.7 mm). The BRS293 variety is of Brazilian origin, with an average height of 126.3 cm and shorter fibers (≤ 26.3 mm) (Yattara & Kassambara, 2020). BRS293 is a variety with high seed-cotton yield potential (> 1,800 kg·ha-1) (Yattara & Kassambara, 2020), but its short fiber length makes it less appreciated by spinners. On the other hand, NTAMS334 has long fibers, but its potential yield is 1,500 kg·ha-1 (Yattara & Kassambara, 2020), hence the choice of these two varieties for comparison in the study. The cycle for two varieties is 120 days. The potential sowing density for both varieties recommended by the research is 83,333 plants·ha-1. Apart from topping and sowing spacing, all cultural practices recommended by the research were respected on Finkolo agricultural research station. This involved phytosanitary protection, quantity and method of fertilizer application, and maintenance of plots to prevent weed growth. However, additional organomineral fertilization was applied during the two years of experimentation, i.e. 5 tons of farm compost per hectare and 51 units of nitrogen per hectare. For phytosanitary protection, the calendar insecticide treatment was used to control pests, with the application of 150 g·l-1 Teflubenzuron at a dose of 100 ml·ha-1 for the first two treatments and Cypermetrine 144 g·l-1 + Imidaclopride 200 g·l-1 at a dose of 250 ml·ha-1 for the third, fourth, fifth, and sixth insecticide treatments. The size of the elementary plot was 12 m x 8 m, i.e. 96 m2. Blocks or replicates were separated by 1.5-m rows. The elementary plots comprised 10 lines 12 m long, spaced 0.8 m.

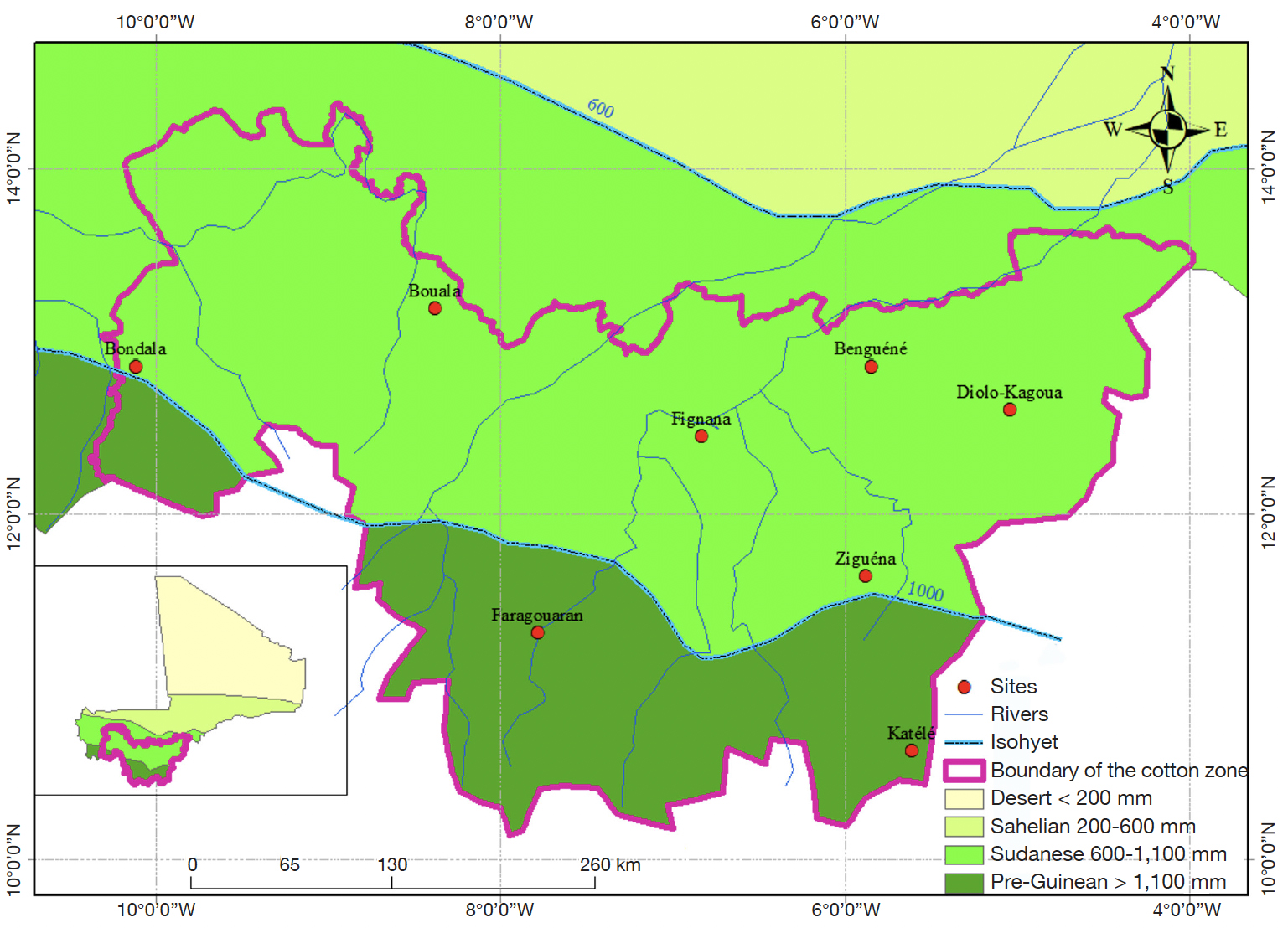

18In cotton farmers’ fields experiment, demonstration plots have been set up with farmers in seven villages (Bondala, Diolo-Kagoua, Fignana, Faragouaran, Béguené, Bouala and Ziguéna) in 2022 (Figure 3). A demonstration plot was set up in each village. The agricultural ecosystems in the study areas are characterized by agroforestry parks, mainly based on shea trees and the soils are of the tropical ferruginous type (Traoré et al., 2022). Sowing dates varied from village to village, with planting taking place between May 25 and July 15. In terms of rainfall, the Faragouaran, Katélé and Bondala sites received the most rain, with over 1,000 mm. On the other hand, rainfall was low in the villages of Benguéné, Diolo-kagoua, Bouala and Fignana, with less than 800 mm. The statistical design used was a dispersed block in which each farmer’s plot constituted a repetition. The combined factor of topping and plant density was the only factor studied in farmers' fields. The demonstration plots were 2,500 m2 each, divided into four items (numbered 1 to 4), as shown in table 2. Item 1 = sowing at 0.80 x 0.30 without topping with 2 plants·hole-1, Item 2 = sowing at 0.80 x 0.30 with topping and 2 plants·hole-1, Item 3 = sowing at 0.80 x 0.20 without topping with 1 plant·hole-1, Item 4 = sowing at 0.80 x 0.20 with topping and 1 plant·hole-1. Only one cotton variety (NTAMS334) was used in these plots. In contrast to the station, 44 units of nitrogen·ha-1 were applied in each demonstration plot, i.e. 150 kg·ha-1 15 days after sowing and 50 kg·ha-1 on the 45th day after.

Figure 3. Location of the seven villages in Mali where demonstration test plots were conducted in 2022 — Localisation des sept villages du Mali où des parcelles tests de démonstration ont été conduites en 2022.

Source: LaboSep/IER.

2.3. Data collection

19To assess the growth of fruiting branches, cotton plants were monitored at the Finkolo agricultural research station. This observation was carried out in each plot along two central lines on a section 1.5 m long per line. For each monitored cotton plant, all fruiting positions on the first 10 fruiting branches were examined. For each position, the presence or absence of a fruiting organ was noted along with its type (bud, flower or boll). The number of fruiting branches per cotton plant was then counted. This observation was performed weekly, starting on day 30 after sowing (DAS) and continuing until 115 DAS. At harvest, the fruit-bearing branches were diagnosed or examined by position, noting whether or not they were bearing a fruiting organ (fully healthy bolls, partially healthy bolls, mummified bolls and rotten bolls). To estimate stand density, the number of plants was counted at harvest in four central rows of each elementary plot. To assess the average boll weight (ABW), the bolls located at different positions of the first 10 fruiting branches of the two central lines were counted, and seed cotton weight was recorded. These lines were also used for monitoring observations for each plot, and ABW was estimated dividing the total weight of seed-cotton by the number of bolls.

20Seed-cotton yield was assessed at harvest using the seed-cotton weight on the four central lines of each elementary plot (useful plot size = 38.4 m²). Harvesting was carried out after more than 90% of the bolls had burst in the useful plots of each treatment. The remaining seed-cotton was harvested during the second pass.

21The technological characteristics of fiber samples from the Finkolo station in 2021 were determined at the CERFITEX cotton fiber analysis laboratory in Ségou, Mali. Fiber sampling was carried out according to the test set-up. Beforehand, a sample of 500 g of seed cotton was taken per treatment. The seed cotton was then cleaned of impurities and ginned using 10 saws. A total of 200 g of cotton fiber per treatment were sampled after ginning seed cotton at the N'Tarla research station and sent to the CERFITEX laboratory. The results obtained were compared with the optimum values required by the textile industry (Yattara & Kassambara, 2020). These are fiber length (UHLM): 28.2 to 28.7 mm, fiber strength or tenacity (Str): 26 to 28 g·tex-1, short fiber content (SFI): 6 to 9%, and fiber length uniformity (UI): 81 à 84%.

2.4. Statistical data analysis

22The General Linear Model (GLM) was used to analyze the effect of sowing density with or without topping on yield components and seed cotton yield, considering the sowing modality as a random effect. The effect of the sowing density combined with topping on the observed variables was tested by ANOVA using a probability threshold of 0.05. The equation of the statistical model used was as follows:

23Yijk = μ+αi+βj+(αβ)ij+ϵijk

24where Yijk is the value of the response variable for observation k in the cell corresponding to the interaction of factors i and j; μ is the overall mean; αi is the effect of the variety factor for level I; βj is the effect of the sowing modality factor combined with the topping factor for level j; (αβ)ij is the effect of the interaction between the cotton variety factor and, for level (i,j), the sowing method combined with topping; ϵijk is the random error associated with observation k in cell (i,j), assumed to be normally distributed with mean zero and variance σ2.

25When the effect of a factor was significant, multiple comparisons were made using Tukey’s test. Statistical analysis was performed using R software (R Core Team, 2021), "Agricolae" package.

3. Results

3.1. Average number of fruit-bearing branches per cotton plant on research station

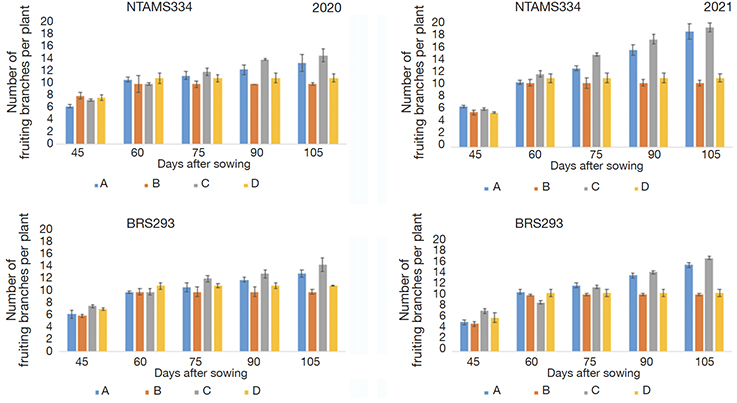

26For experiments carried out in 2020 and 2021, analysis of figure 4 shows that the number of fruiting branches increased for the two cotton plant densities from 45 to 60 days after sowing (DAS). For these first two observation dates, the analysis of variance showed no significant difference (p = 0.56) between either the cotton plant densities or the varieties in 2020 and 2021 experiments. The average number of fruiting branches varied between 6 and 11 (Figure 4). From 60 DAS, a gradual increase in the number of fruit-bearing branches was observed in modalities without topping (A and C). Modalities with topping (B and D) remained unchanged because of topping carried out 65 DAS. Significant differences (p = 0.04) between sowing modalities were observed by analysis of variance. On the other hand, the interaction between variety and sowing density was not significant (p = 0.70; 0.47 and 0.74) at 75, 90, and 105 DAS, respectively. In 2020, the average number of fruiting branches at 105 DAS ranged from 14 to 15 for modalities without topping and from 10 to 11 for modalities with topping. In 2021, at the same observation date, the average number of fruit-bearing branches was 18 for the modalities without topping and 10 for the modalities with topping.

Figure 4. Estimated number of fruiting branches per cotton plant according to the four modalities and two varieties tested in 2020 (on the left) and 2021(on the right) at Finkolo agricultural research station — Estimation du nombre de branches fructifères par cotonnier selon les quatre modalités et les deux variétés testées en 2020 (à gauche) et 2021 (à droite) à la station de recherche agricole de Finkolo.

A: cotton sowing at 80 cm x 30 cm without topping — semis de coton à 80 cm x 30 cm sans écimage; B: cotton sowing at 80 cm x 30 cm with topping — semis de coton à 80 cm x 30 cm avec écimage; C: cotton sowing at 80 cm x 20 cm without topping — semis de coton à 80 cm x 20 cm sans écimage; D: cotton sowing at 80 cm x 20 cm with topping — semis de coton à 80 cm x 20 cm avec écimage; NTAMS334, BRS293: cotton variety names — noms de variété de coton; for each value, the vertical line indicates its confidence interval at 5% threshold — pour chaque valeur, la ligne verticale indique son intervalle de confiance au seuil de 5 %.

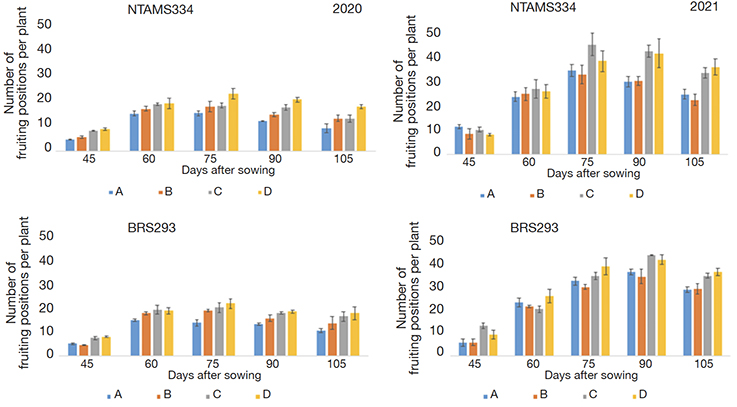

3.2. Average number of fruiting organs present at each cotton plant position on research station

27The average number of fruiting organs present at each cotton plant position (Figure 5) showed that modalities C and D, with one plant in each seed hole and a spacing of 20 cm between two plants on the row, produced a higher number of fruiting organs than modalities A and B, sown according to recommendations (two plants per seed hole and a spacing of 30 cm between two plants on the row). Although the growth in size of fruiting organs in modality D was halted by topping at 65 DAS, the average number of fruiting organs per plant was higher at 105 days after sowing than that observed with modalities A and B, but similar to that obtained with modality C (Figure 5). The average number of fruiting organs per plant was higher in 2020 (15) and in 2021 (35) at 105 DAS for the 80 cm x 20 cm sowing spacing associated with the practice of topping, regardless of the variety (Figure 5). Analysis of variance showed no significant difference at the 5% threshold between varieties or between densities regarding the average number of fruiting positions on 45 and 60 DAS. At 75, 90, and 105 DAS, a significant effect at the 5% threshold was established between modalities (p = 0.03). The number of fruiting organs produced by modalities D and C was significantly higher than those produced by modalities A and B (Figure 5). No significant effect was observed between varieties, and the variety x modality interaction was not significant. In addition, more fruiting organs were observed in 2021 than in 2020, due to the poor rainfall observed in 2020 (1,254 mm in 2021 vs 930 mm in 2020).

Figure 5. Estimated number of fruiting positions per cotton plant according to the four modalities and two varieties tested in 2020 (on the left) and 2021 (on the right) at Finkolo agricultural research station — Estimation du nombre de positions fructifères par cotonnier selon les quatre modalités et les deux variétés testées en 2020 (à gauche) et 2021 (à droite) à la station de recherche agricole de Finkolo.

A, B, C, D, NTAMS334, BRS293: see figure 4 — voir figure 4; for each value, the vertical line indicates its confidence interval at 5% threshold — pour chaque valeur, la ligne verticale indique son intervalle de confiance au seuil de 5 %.

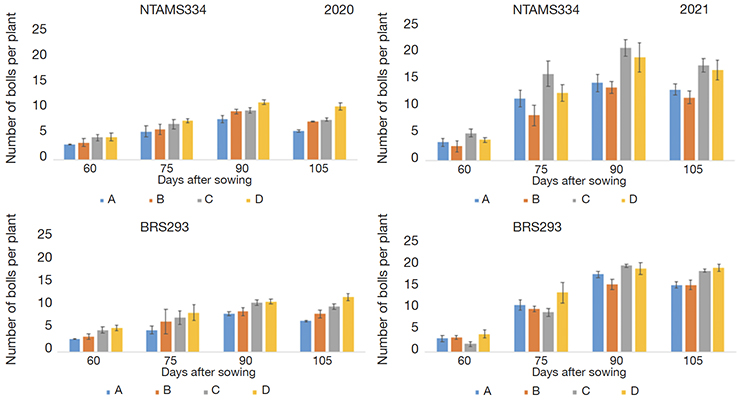

3.3. Boll load per plant on research station

28The boll load per plant was influenced by cotton plant density and topping practice. An average of 10 bolls per plant were counted at 105 DAS for both cotton varieties in 2020, in favor of modality D (Figure 6). In 2021, 19 bolls were counted in favor of modality D and variety BRS293 (Figure 6). Overall, modalities D and C produced more bolls than modalities A and B, regardless of the variety in our experimental conditions (Figure 6). Analysis of variance revealed a significantly high effect of the number of bolls at 90 (p = 0.04) and 105 DAS (p = 0.02) in favor of modalities C and D in 2020 (Figure 6). However, the analysis did not reveal any significant difference between modalities at 45 and 75 DAS. The average number of bolls per plant at 105 DAS was 8 for NTAMS334 and 9 for BRS293 in 2020. In 2021, the average number of bolls per plant at 105 DAS was 15 for the NTMS334 variety, compared with 17 bolls per plant for the BRS293 variety.

Figure 6. Estimated number of bolls per cotton plant from 60 and 105 days after sowing according to the four modalities and two varieties tested in 2020 (on the left) and 2021 (on the right) at Finkolo agricultural research station — Estimation du nombre de capsules par cotonnier à partir du 60e jour après semis jusqu’au 105e jours après semis selon les quatre modalités et les deux variétés testées en 2020 (à gauche) et 2021 (à droite) à la station de recherche agricole de Finkolo.

A, B, C, D, NTAMS334, BRS293: see figure 4 — voir figure 4; for each value, the vertical line indicates its confidence interval at 5% threshold — pour chaque valeur, la ligne verticale indique son intervalle de confiance au seuil de 5 %.

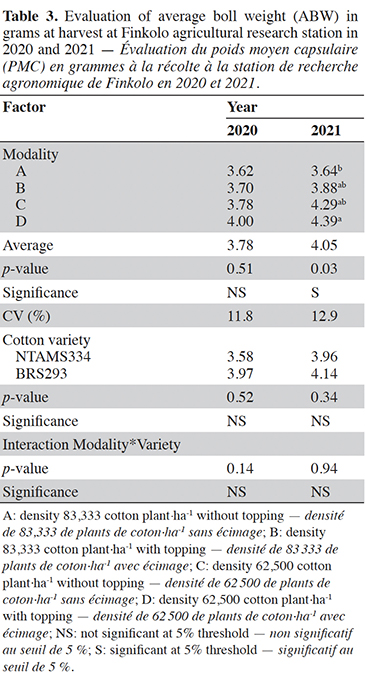

3.4 Average boll weight at harvest on research station

29Analysis of variance did not reveal any significant effect on average boll weight (ABW) between cotton plant densities or varieties in 2020 (Table 3). In 2020, ABW was 3.78 g. In 2021, analysis of variance revealed a significant difference (p = 0.03) between modalities on ABW. ABW for modalities with topping (B and D) was significantly higher than those obtained for modalities without topping (A, C) (Table 3). No significant effect was established by analysis of variance between the two varieties (Table 3), and the variety x modality interaction was not significant. ABW for the trial was 4.10 g in 2021 (Table 3). The coefficients of variation were 11.8% in 2020 and 12.9% in 2021, indicating average variability in ABW.

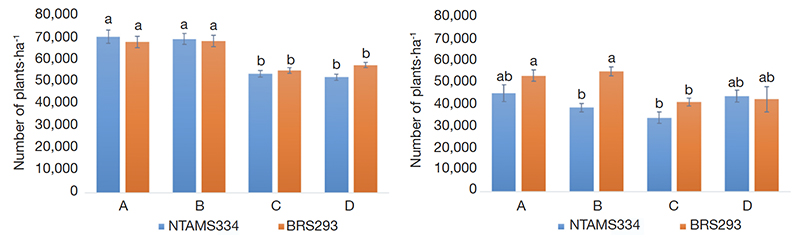

3.5. Cotton plant density at harvest on research station

30Figure 7 shows the estimated cotton plant density at harvest. The average value was influenced by the sowing spacing in 2020 and 2021 experiments. In 2020, the average density at harvest was 70,000 plants·ha-1 for modalities A and B, i.e. 84% of the theoretical density (83,333 plants·ha-1). For modalities C and D, the average density was estimated to be 54,000 plants·ha-1, which represents 86% of the theoretical density (62,500 plants·ha-1). Analysis of variance of density revealed a significant difference (p = 0.02) between the modalities, with significantly higher values for modalities A and B compared to modalities C and D (Figure 7). In 2021, the average density estimated at harvest was low compared with 2020. In 2021, the highest density was observed in plots of modalities A and B with the variety BRS293 (Figure 7), and the majority of hole had only one plant at harvest. Analysis of variance showed a significant difference (p = 0.01) between modalities and between cotton varieties in terms of the number of plants·ha-1 (Figure 7). Variability in the number of plants in the trial during the two years of experimentation was low overall, except in the plots of modality D with the variety BRS293 in 2021 (Figure 7).

Figure 7. Classing of estimated number of plants.ha-1 according to the four modalities and two varieties tested in 2020 on the left and 2021 on the right at Finkolo agricultural research station — Nombre de plants.ha-1 selon les quatre modalités et les deux variétés testées en 2020 (A) à gauche et 2021 (B) à droite à la station de recherche agronomique de Finkolo.

A, B, C, D, NTAMS334, BRS293: see figure 4 — voir figure 4; for each value, the vertical line indicates its confidence interval at 5% threshold — pour chaque valeur, la ligne verticale indique son intervalle de confiance au seuil de 5 %.

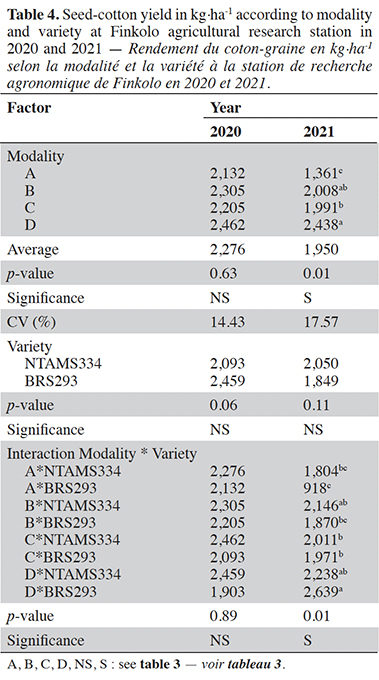

3.6. Seed-cotton yield on research station

31Table 4 shows seed-cotton yields for the two years of on-station experimentation. The analysis of variance showed no significant difference between the sowing methods or between the two cotton varieties in 2020, and the average yield was 2,276 kg·ha-1 (Table 4). Seed-cotton yield was influenced by sowing density and topping practice in 2021. Analysis of variance showed a significant difference (p = 0.01) between sowing modalities for seed-cotton yield in 2021, and the highest yield (2,639 kg·ha-1) was obtained in the D-modality plots. The seed-cotton yield obtained with this sowing method combined with topping was statistically different from the seed-cotton yield obtained in the plots of modalities A and C in 2021 (Table 4). However, no significant effect was observed by analysis of variance between cotton varieties. The interaction between the sowing methods and varieties was significant. The coefficient of variation was on the order of 14.4% in 2020 and 17.6% in 2021, indicating that yields were more stable in 2020 than in 2021.

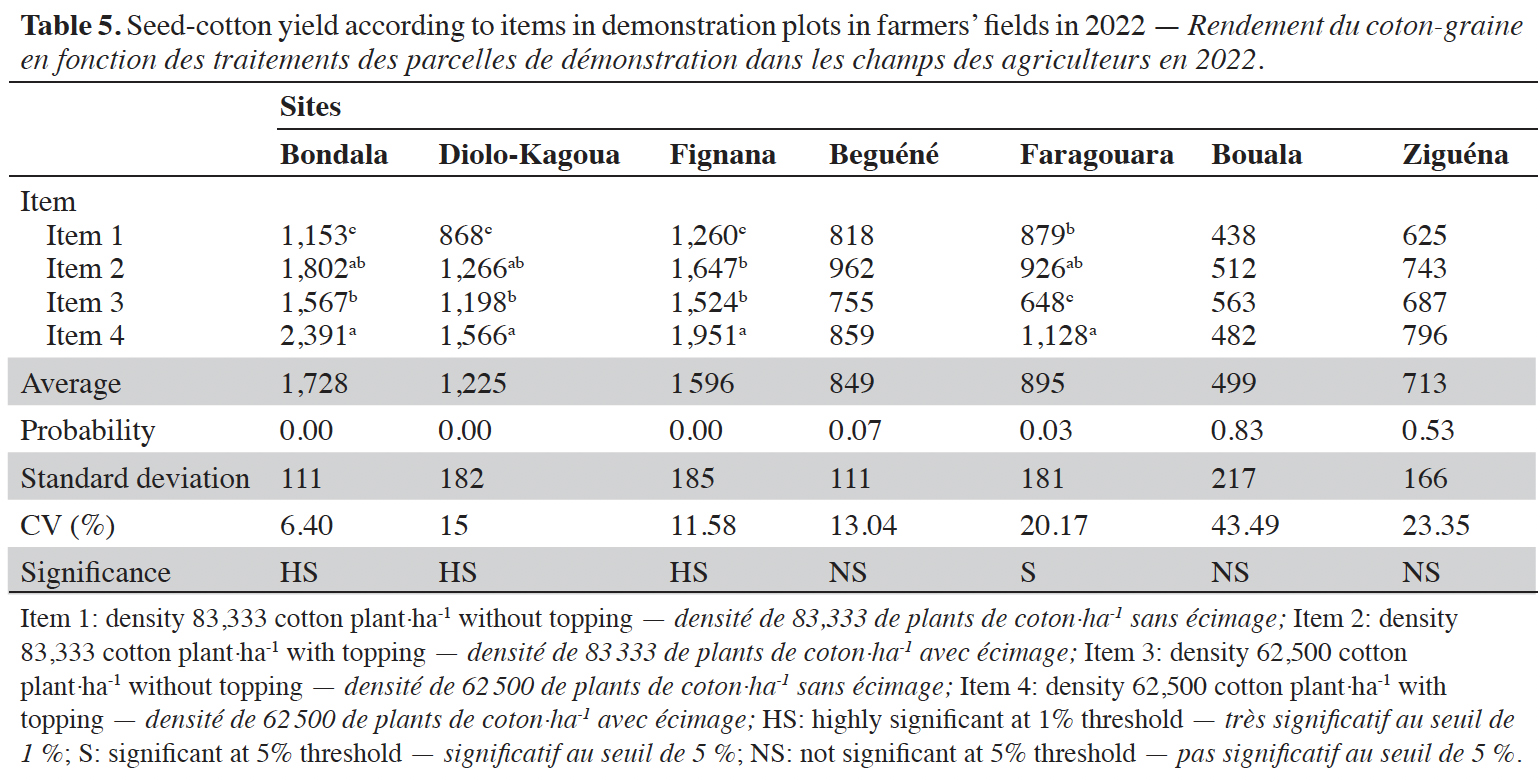

3.7. Influence of cotton plant density and topping on seed-cotton yield in demonstration plots

32Among demonstration plots located in farmers’ fields, a significant difference in seed-cotton yield was observed between Bondala, Diolo-Kagoua, Fignana, and Faragouaran sites (Table 5). The highest seed-cotton yields were obtained in the plots hosting item 4 (density 62,500 plant·ha-1 with topping). It was statistically different from item 1 (density 83,333 plants·ha-1 without topping) on all four sites. Seed-cotton yields on Béguéné, Bouala, and Ziguéna sites were low overall, and no significant differences were revealed by analysis of variance (p = 0.83 at Bouala and 0.53 at Ziguéna) (Table 5). The lowest seed-cotton yield was obtained in the village of Bouala and the highest in the village of Bondala.

3.8. Fiber quality parameters

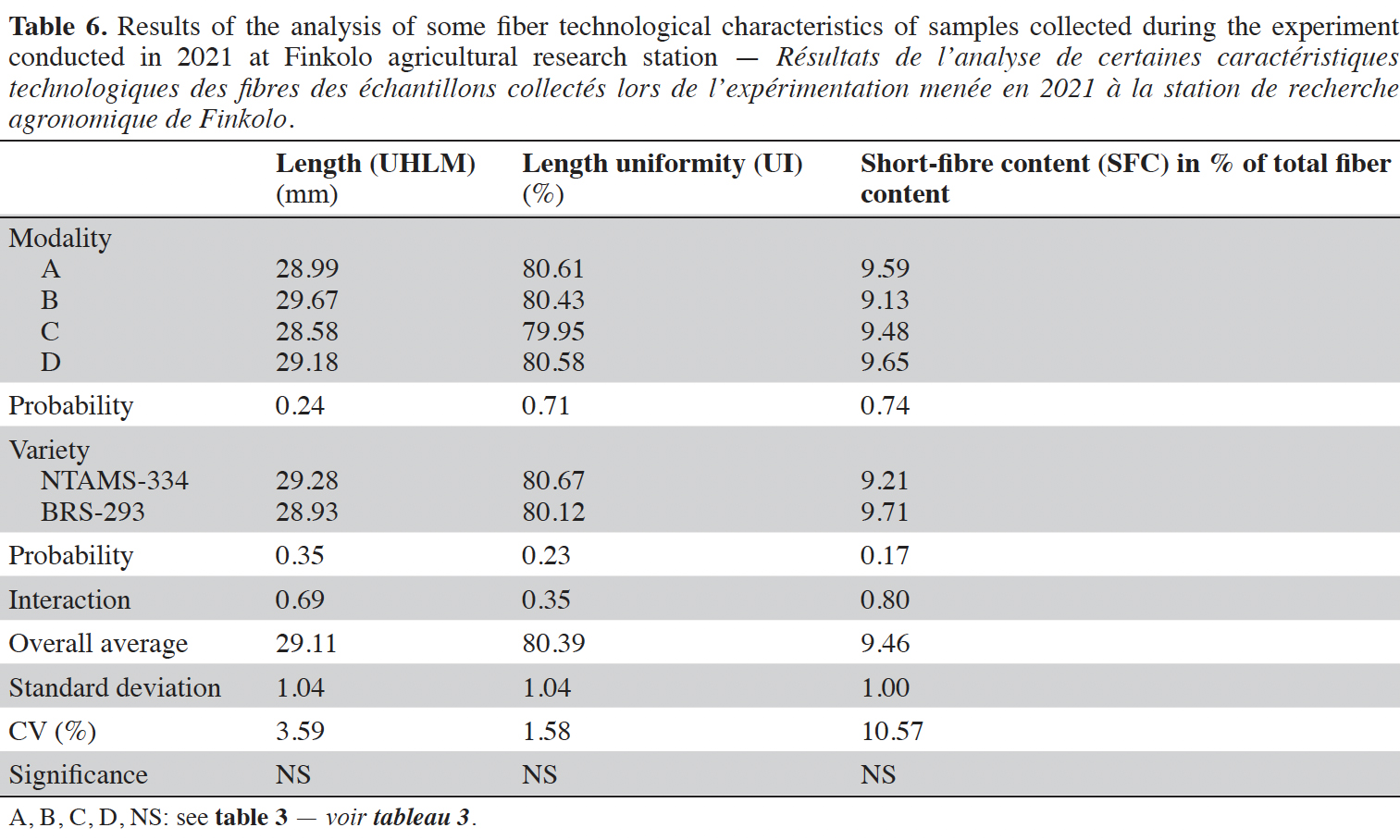

33The technological analysis of fiber samples, collected during the experiment conducted on the station in 2021, shows an improved fiber length (UHML) for modalities B and D (with topping) compared with modalities A and C (without topping) (Table 6). Analysis of variance did not reveal any significant difference (p > 0.05) between the modalities or varieties in regard to fiber length, fiber uniformity, and short fiber rate under our experimental conditions (Table 6). The average fiber length was 29.11 mm, which is above the threshold required by the textile industry (≥ 28.2 to 28.7). On the other hand, fiber length uniformity was slightly below the required threshold (≥ 81 to 84), with an average of 80.39 (Table 6). The average short-fibre content was 9.5%, which is above the threshold required by the textile industry (≤ 6 to 9%).

4. Discussion

34Sowing density is one of the key factors in improving cotton productivity (Soomro et al., 2000; Khan et al., 2005; Yang et al., 2014). Very low or very high sowing densities can compromise crop yield (Ciampitti & Vyn, 2011). Some studies, such as those by Soomro et al. (2000), report increases in cotton yield under a spacing of 20 cm to 30 cm between two cotton plants. Others, such as Jagannathan & Venkitaswamy (1996), reported a decrease in seed cotton yield with increasing seeding density. Reducing sowing spacing, i.e. sowing geometry, increases the number of plants. Our study evaluates plant density, sowing geometry and cotton topping. In what follows, we successively discuss the influence of sowing density and cotton topping on fruiting branches and average capsular weight, the influence of sowing density and topping on seed cotton yield and the influence of sowing density and topping on fiber quality.

4.1. Influence of sowing density and cotton topping on agronomic parameters

35Fruiting branches evolved progressively in the case of seedling modalities not topped, whereas those topped stopped growing in height when topping was applied at 65 DAS. The number of fruit-bearing branches was significantly higher in the unpruned seedling modalities (between 14 and 15 fruit-bearing branches on day 105 after sowing) than in the pruned ones (between 10 and 11 fruit-bearing branches on day 105 after sowing). This result is in agreement with that found by Traoré et al. (2017). The capsular load per plant was higher in favor of sowing modality D during both years of experimentation. Several other authors, including Renou (2015), Jianlong et al. (2017), Traoré et al. (2017), have shown that the practice of topping results in a significant increase in the number of bolls.

4.2. Influence of sowing density and topping on seed-cotton yields

36Plant density·ha-1 was significantly higher for sowing modalities A and B in both years of experimentation. The highest seed-cotton yield (2,462 kg·ha-1 in 2020 and 2,639 kg·ha-1 in 2021) was obtained with sowing modality D. But in 2020, modality C without topping also produced high yields. In our study, the effect of topping was not constant from one year to the next. But studies such as those carried out by Renou et al. (2011) suggest that topping practices improve yield by allocating more biomass to reproductive organs, such as green bolls. Similar results were reported by Singh & Sandhu (1996), where topping also resulted in significantly higher yields of seed-cotton compared with no topping. Other authors such as Brar et al. (2002) reported that plant height was significantly reduced by topping, but seed-cotton yield increased significantly. Damodaran et al. (1974) and El-Hanafi et al. (1982) reported that the beneficial effects of topping on yield depended on the date of topping. On the other hand, according to Dhamalingam et al. (1974), the effects of topping depend more on variety. Other studies associated topping with certain cultural practices, such as sowing density, have also shown positive effects on yield (Rahman et al., 1991; Mafu et al., 2002; Obasi & Msaakpa, 2005).

4.3. Influence of sowing density and topping on fiber quality

37The modalities including cotton plant topping produced fiber with a length (UHML > 29 mm) longer than the one of modalities without topping (UHML between 28 and 29 mm). This result is higher than the threshold required by the textile industry (28.2 to 28.7 mm). The overall average for short fiber content was 9.5%, which is higher than the maximum threshold required by the textile industry (6 to 9%). The rate of short fibers was lower with modality B in the study. Topping had no negative effect on micronaire index. Micronaire index values ranged from 4.4 to 5.1 for cotton plants without topping and from 4.6 to 5.0 for cotton plants with topping. These values do not fall below the threshold required by the textile industry (3.8 and 4.2). Overall, the technological characteristics analyzed for both varieties exceed the thresholds required by the textile industry in this study.

5. Conclusions

38Cotton topping combined with a change in sowing density clearly shows that cotton yields have not been affected by topping, but that yield levels have increased in some cases, as plant structure changes due to the end of apical dominance in cotton. The highest yield on station was obtained using modality D (sowing spacing 80 cm between rows and 20 cm between plants with one plant per hole). In the farmers' fields, the best yield was obtained with plot 4 (sowing spacing 80 cm between rows and 20 cm between plants with one plant per hole. In our study, although the effect of topping was not constant from one year to the next on Finkolo research station, among farmers demonstration plots the best yield was obtained with seedling spacing of 80 cm between rows and 20 cm between plants, with one plant per hole). Also, the modalities with topping showed a higher fiber length than modalities without topping. Thus, the results of the present study can be used to modify canopy and seeding density under conditions of excessive cotton growth to improve certain yield components. However, the two years of the study may not be sufficient to fully investigate the effect of topping combined with modified seedling spacing, and this may well be a limitation of this study. Farmers' perception of the technology could be a further study to be carried out.

Bibliographie

Ahmed F.M., Abdel Al M.H. & Ismail M.S., 1989. Effect of topping and cycocel application time on the productivity of cotton (Gossypium barbadense). Assuit J. Agric.Sci., 20(6), 313‑325.

Akhtar M.E. et al., 2003. Effect of potash application on seed cotton yield and yield components of selected cotton varieties-I. Asian J. Plant Sci., 2(8), 602‑604, doi.org/10.3923/ajps.2003.602.604

Brar A., Novtej S. & Deol J., 2002. Influence of plant spacing and growth modification practices in yield and its attributing characters of two cotton cultivars (G. hirsutum). J. Res. Punjab Agric. Univ., 39(2), 181‑183.

Ciampitti I.A. & Vyn T.J., 2011. A comprehensive study of plant density consequences on nitrogen uptake dynamics of maize plants from vegetative to reproductive stages. Field Crops Res., 121(1), 2‑18, doi.org/10.1016/j.fcr.2010.10.009

CMDT, 2022. Le coton, un facteur de développement, https://www.cmdt-mali.net/index.php/entreprise/organisation.html, (27/11/2024).

CNUCED, 2016. Coton. Un profil de produit de base par INFOCOMM. Genève, Suisse : CNUCED.

Damodaran A. et al., 1974. Influence of topping on the characters of American cotton (G. hirsutum). Madras Agric. J., 61, 855‑857.

Dhamalingam,V., Krishnadoss D., Robinson I. & Lyemperumal S., 1974. Effect of topping rainfed cotton. Madras Agric. J., 9(6), 858‑860.

Diarra M., Havard M. & Soumaré M., 2020. La perception des avantages et des contraintes de l’écimage du cotonnier par les producteurs du Mali. Cah. Agric., 29(10), 7, doi.org/10.1051/cagri/2020007

Diouf F. et al., 2017. État des lieux de l’amélioration du cotonnier au Sénégal et perspectives de recherches. In : Actes du colloque, Dynamiques et durabilité des zones cotonnières africaines, 21-23 novembre 2017, Bamako, Mali.

El-Hanafi H.R. et al., 1982. Influence of topping on cotton yield and other characteristics. Agric. Res. Rev., 60(9), 153‑163.

ESRI, 2021. Sentinel-2 10m land use/land cover time series, https://www.arcgis.com/home/item.html?id=cfcb7609de5f478eb7666240902d4d3d, (12/12/24).

Jagannathan N.T. & Venkitaswamy R., 1996. Effect of plant density and nutrient levels on new cotton varieties. Madras Agric. J., 83(3), 159‑161.

Jianlong D. et al., 2017. Competitive yield and economic benefits of cotton achieved through a combination of extensive pruning and a reduced nitrogen rate at high plant density. Field Crops Res., 209, 65‑72, doi.org/10.1016/j.fcr.2017.04.010

Khan K., Mahmood Z., Soomro A.R. & Illahi N., 2005. Seed cotton yield as influenced by different plant spacings under D. I. Khan environment. Indus Cottons, 2(2), 147-150.

Kumari S.R. & George M., 2012. Physiological manipulation of plant morphoframes by maleic hydrazide and through nipping for enhancing cotton yield. Green Farming Int. J. Appl. Agric. Hortic Sci., 3(6), 677‑679.

Lawson A.J., 2008. Effet de différentes pratiques de taille sur l’amélioration des performances agronomiques du cotonnier Gossypium hirsutum L. Mémoire : Université de Parakou (Bénin).

Mafu Y. et al., 2002. A study on the fitness of cotton on canopy regulated by topping under high yield condition. Sci. Agric. Sin., 37(12), 1843‑1848.

Muhammad D.M., Anwar M., Zaki M.S. & Afzam M.N., 2002. Effect of plant population and nitrogen variables on cotton crop. Pak. Cottons, 47(1-2), 37‑41.

Obasi M.O. & Msaakpa T.S., 2005. Influence of topping, side branch pruning and hill spacing on growth and development of cotton (Gossypium barbadense L.) in the southern Guinea savanna location of Nigeria. J. Agric. Rural Dev. Trop. Subtrop. (JARTS), 106(2), Article 2.

PIRT (Projet Inventaire des Ressources Terrestres), 1986. Les ressources terrestres au Mali. Rapport technique. Vol. II. Gouvernement de la République du Mali. USAID/TAMS B3-B41.

PR PICA, 2022. Rapport de synthèse de la quatorzième réunion bilan du Programme Régional de Production Intégrée du Coton en Afrique (PR-PICA), 28-30 mars 2022, Dakar, Sénégal, https://prpica.org/wp-content/uploads/2022/04/Rapport-14eme-Reunion-Bilan-PR-PICA-Dakar_mars_2022.pdf, (27/11/2024).

R Core Team, 2021. Agricolae: statistical procedures for agricultural research. R package version 1.3-5, https://CRAN.R-project.org/package=agricolae, (12/12/24).

Rahman M., Karim A. & Maniruzzaman A., 1991. Effect of topping of cotton sown different dates. Bangladesh. J. Sci. Ind. Res., 29, 149‑157.

Renou A., 2015. Synthèse des études conduites au Mali à propos de l’écimage des cotonniers en cours de campagne. [Rapport de synthèse]. CIRAD UPR 102.

Renou A., Téréta I. & Togola M., 2011. Manual topping decreases bollworm infestations in cotton cultivation in Mali. Crop Prot., 30(10), 1370‑1375, doi.org/10.1016/j.cropro.2011.05.020

Roy N.C., Sarkar R. & Malek M.A., 1989. Effect of topping on cotton at different plant population. In: Proceedings of the 14th Annual Bangladesh Scientific Conference, Section 1, 103.

Singh J. & Sandhu B., 1996. Effect of detopping in cotton on the efficacy of chemical control of boll worms. J. Indian Soc. Cotton Improv., 21, 56‑57.

Sissoko F., 2009. Analyse des flux d’eau dans les systèmes de culture sous couverture végétale en zone soudano sahélienne : cas du coton semé après une culture de sorgho/Brachiaria au sud du Mali. PhD thesis : Montpellier SupAgro (France).

Soomro A.R. et al., 2000. The effect of different sowing dates on the yield of newly developed strain under climatic conditions of Ghotki, Sindh. Pak. J. Biol. Sci., 3(11), 1901‑1903, doi.org/10.3923/pjbs.2000.1901.1903

Soumaré M. & Havard M., 2018. Guides méthodologiques. Fiches techniques. Innovations pour l’amélioration de la productivité et de la durabilité des systèmes d’exploitation à base de coton au Mali. Bamako : IER-CIRAD.

Soumaré M. & Traoré S., 2019. Zonage agricole des zones cotonnières du Mali, Planche 1. In : Soumaré M. et al., eds. Atlas des zones cotonnières du Mali. 2è éd. Bamako : IER-CIRAD, 15-18.

Soumaré M. et al., 2019. Atlas des zones cotonnières du Mali. Bamako : IER-CIRAD.

Tereta I., 2015. Contribution à l’amélioration de la protection phytosanitaire de la culture cotonnière au Mali : effets de l’écimage manuel sur les populations des chenilles de la capsule. Thèse de doctorat : Université des Sciences, des Techniques et des Technologies de Bamako (Mali).

Traoré A., Sissoko F. & Sissoko M., 2017. Effet de l’écimage sur les caractéristiques agro-physiologiques du cotonnier en zone nord guinéenne du Mali. In : Actes du colloque, Dynamiques et durabilité des zones cotonnières africaines, 21-23 novembre 2017, Bamako, Mali, 451-456.

Traoré A. et al., 2022. Projet d’appui à la transition agroécologique en zone cotonnière, AgrECO. Composante 2 : Recherche & Développement. Activités : Exploitation durable des espaces et des ressources [Rapport de campagne 2019-2020]. Bamako : Institut d’économie Rurale, 82.

Yang G., Luo X., Nie Y. & Zhang X., 2014. Effects of plant density on yield and canopy micro environment in hybrid cotton. J. Integr. Agric., 13(10), 2154‑2163, doi.org/10.1016/S2095-3119(13)60727-3

Yattara A.A. & Kassambara E.M., 2020. Mise au point de variétés (ordinaires et glandless) de cotonnier à rendement stable de coton graine, à qualité technologique de fibre améliorée et à forte potentialité des graines [Rapport de campagne 2019-2020]. Bamako : Institut d’économie Rurale, 73.