- Home

- Volume 19 (2015)

- numéro 3

- The influence of biocalcification on soil-cement interlocking block compressive strength

View(s): 0 (0 ULiège)

Download(s): 0 (0 ULiège)

The influence of biocalcification on soil-cement interlocking block compressive strength

Editor's Notes

Received on July 20, 2014; accepted on March 16, 2015

Résumé

Influence de la bio-calcification sur la résistance en compression des blocs autobloquants à base de sol-ciment

Description du sujet. Le bloc autobloquant en sol-ciment est largement utilisé comme bloc de construction pour de nombreuses structures civiles en Thaïlande. Bon nombre de recherches sur le mélange de matériaux alternatifs pour la fabrication de blocs autobloquants sont menées afin d'améliorer sa résistance en compression. Cependant, il n'existe actuellement aucune recherche sur l’influence de l’application de la bio-calcification ou de la précipitation de calcite induite biologiquement sur la résistance en compression du bloc autobloquant.

Objectifs. Cette étude a été conçue pour étudier l'effet de bio-calcification sur la résistance à la compression du bloc autobloquant en sol-ciment.

Méthode. Des bactéries du sol, Bacillus pasteurii KCTC 3558, et micro-organismes efficaces (EM) ont été ajoutés en remplacement de l'eau dans le bloc avant de le modeler. La variation de la résistance en compression dans le bloc autobloquant a été déterminée après 3, 7, 14 et 28 jours d'incubation.

Résultats. Les résultats montrent qu'à 28 jours, les résistances en compression du bloc autobloquant, avec le B. pasteurii KCTC 3558 et 5 % EM, étaient de 7,38 % et 9,79 % plus élevées que le mélange de contrôle et l’observation de cristaux de carbonate de calcium sous un microscope électronique à balayage (SEM) confirme que l'augmentation de la résistance en compression du bloc autobloquant a été causée par la bio-calcification.

Conclusions. Nos résultats ont montré que les précipitations de calcite microbiologiquement induites pourraient aider à augmenter la résistance en compression du bloc autobloquant en sol-ciment.

Abstract

Description of the subject. Soil-cement interlocking block is used as the building block for many civil structures in Thailand. The addition of many alternative materials into interlocking block in order to improve compressive strength has been reported. However, there is currently no report on the influence of application of biocalcification or microbiologically induced calcite precipitation (MICP) on interlocking block compressive strength.

Objectives. This study aimed to investigate the effect of biocalcification on compressive strength of soil-cement interlocking block.

Method. Soil bacterium, Bacillus pasteurii KCTC 3558, and Effective Microorganisms (EM) were added into interlocking block before molding as the replacement of mixing water. The change of compressive strength in interlocking block at 3, 7, 14 and 28 days of incubation was determined.

Results. At 28 days, the compressive strength of interlocking block supplemented with B. pasteurii KCTC 3558 and 5% EM were 7.38% and 9.79% significantly higher than control. Calcium carbonate crystals were also observed under scanning electron microscope which suggested that an increased compressive strength of interlocking block was caused by biocalcification.

Conclusions. Our results showed that microbiologically induced calcite precipitation could help increasing the compressive strength of soil-cement interlocking block.

Table of content

1. Introduction

1Interlocking block is a common construction material which was used as the building blocks for many civil structures. It can be used for all types of building from wells, houses to schools and resort buildings. Interlocking block is an environmental friendly construction material because during its manufacturing process, less energy was consumed and almost no carbon dioxide is produced. Furthermore, there is no need for skilled labor during construction using interlocking block which makes it easy to use and helps shortening the construction time (Thailand Institute of Scientific and Technical Research, 1985; Anand et al., 2005). Interlocking blocks can be divided into two types based on its raw materials: soil-cement block, a soil based block which was used in this study and a concrete block, in which the major component is cement.

2Production of interlocking block using industrial waste as supplementary material in order to improve some qualities has been reported. Many industrial wastes can be used as supplement for interlocking block production such as coconut shell ash from power plants that use coconut shell coal as fuel, blast furnace slag which is a waste generated from steel industries, molten slag from burning refuse in fluidized-bed gasification furnace (Hosokawa et al., 2004), silica fume from silicon metal industries (Thailand’s Department of Industrial, 2012) and kaolinite top soil from kaolinite mines (Kokkhamheang et al., 2008).

3Biocalcification also known as microbiologically induced calcite precipitation (MICP), is a normal biochemical process that naturally occurs in many environments such as sea water, fresh water and soil. During this process calcium carbonate accumulates due to the activity of urease-producing microorganisms (Douglas et al., 1998; Hammes et al., 2002).

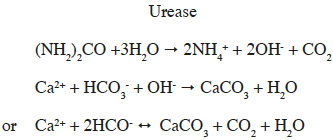

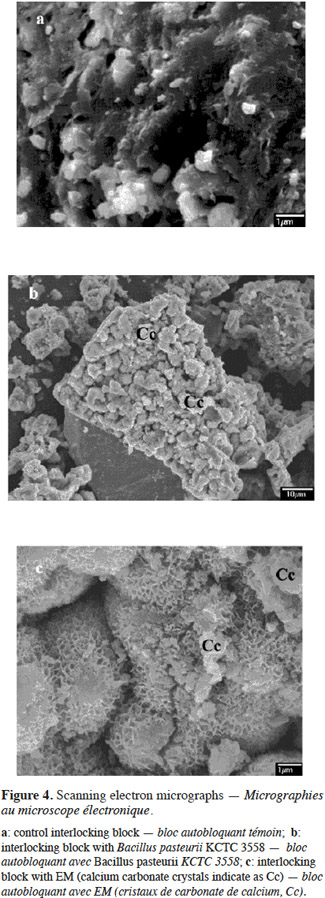

4Calcium carbonate precipitation occurs in nature when the concentration of calcium ion, and/or carbonate ion increases. Precipitation can be induced by physical processes such as changes in temperature or pressure or by the activities of microorganisms (Fujita et al., 2000; Hammes et al., 2003). The utilization of urea results in an increasing of the environment pH which causes calcium ions and carbonate ions to precipitate in form of calcium carbonate according to the following equations:

5Urease hydrolyzes urea to carbonate and ammonium ions that increase the pH in an environment. Calcium carbonate precipitation occurs when Ca2+ is present in the environment.

6There are reports on the use of biocalcification for repairing the surface of the stone and cement concrete (Stocks-Fischer et al., 1999; Ramachandran et al., 2001). In addition, some ureolytic bacteria were able to improve the properties of concrete such as increased compressive strength (Ghosh et al., 2005; Ramakrishnan et al., 2005) and decreased permeable property. These resulted in an increasing resistance to degradation of cement mortars (De Muynck et al., 2007), bricks (Sarda et al., 2009), conventional red bricks (Raut et al., 2014). Recently, urease producing bacteria was used for concrete strength improvement and as concrete deteriorating mold inhibition agent (Park et al., 2012a).

7All previous reports mentioned above demonstrated that biocalcification could be used to improve the properties of concrete and brick. However, to the best of our knowledge, no research on using MICP to improve the strength of soil-cement interlocking block has been reported. This study was designed to investigate the influence of microbial induced calcite precipitation on the compressive strength of soil-cement interlocking block. The comparison was done between Bacillus pasteurii KCTC 3558, a known urease producer, and effective microorganisms (EM). Compressive strength was determined using standard method. Scanning electron microscope was also used to detect calcite precipitation within the interlocking block.

2. Materials and methods

2.1. Microorganisms

8Bacillus pasteurii KCTC 3558 was obtained from Korean Collection for Type Cultures (KCTC). Effective microorganism was purchased from EM Kyusei Company Limited, Chiang Mai, Thailand. They were used as the source of urease in this study. Bacillus pasteurii KCTC 3558 was cultured in production media modified after Smith et al. (1993) containing yeast extract (0.5 g·l-1), (NH4)2SO4 (2.6 g·l-1), MgSO4.7H2O (1 g·l-1), NiSO4.7H2O (0.032 g·l-1), KH2PO4 (2.4 g·l-1), K2HPO4 (5.6 g·l-1), CaCl2 (0.3 g·l-1), urea (10 g·l-1) at 37 °C on rotary shaker (150 rpm) for 24 h in order to obtain an approximate cell density of 5.5 x 106 CFU·ml-1 without transferring culture into new fresh growth medium. Effective microorganisms (5% [v/v]) were prepared by diluting EM in production media before adding to an interlocking block.

2.2. Microbial calcite deposition in interlocking block

9Three sets of 40 blocks of soil-cement interlocking blocks were made from local factory in Chiang Mai province, Thailand which were:

10– soil-cement interlocking block without added bacteria (control);

11– soil-cement interlocking block with B. pasteurii KCTC 3558 in urease production media;

12– soil-cement interlocking block with urease production media + 5% (v/v) EM added as replacement for mixing water.

13Portland cement type I and red earth were used for interlocking block production. Red earth was sieved through 4 x 4 cm2 grid prior to manufacturing process (Figure 1a). The cement to soil ratio was fixed at 1:6 (by weight). Small amount of mixing water (3.7 – 4.0% of total weight of cement and soil) was added to moisten the mixture before mixing in pan mixer (Figure 1b). The resultant mixture was molded in 12.5 x 25 x 10 cm2 mold in hydraulic compressing machine (Figure 1c). All sets of interlocking block were sprayed with water and moist incubated indoor under plastic sheet for up to 28 days (Figure 1d). After 28 days of incubation, color and appearance of the surface of interlocking block were observed.

2.3. Compressive strength determination

14Compressive strength measurement was carried out according to standard method of ASTM C 67- 07 (American Society for Testing and Materials, 2007). Five blocks from each set were sampled and tested for compressive strength at 3, 7, 14, and 28 days of incubation. Each block was dried overnight and weighed. Surface of the block was capped with quick-hardening cement and the cap was aged for at least 24 h prior to a compressive strength test. Compressive strength of each specimen can be calculated as follows:

15Compressive strength, C = W / A

16Where C is the compressive strength of the specimen, lb·in-2 (or kg·cm-2) (or Pa·104), W is the maximum load, lbf, (or kgf) (or N), indicated by the testing machine, and A is the average of the gross areas of the upper and lower bearing surfaces of the specimen, in2 (or cm2).

2.4. Statistical analysis

17The data were expressed as mean ± standard deviation. One way ANOVA was used for statistical analysis. Duncan’s test was used to compare mean in order to determine statistically differences (p < 0.05) between compressive strength of control, samples mixed with production media and B. pasteurii KCTC 3558 and samples mixed with production media and 5% (v/v) EM on the same day of incubation.

2.5. SEM analysis

18Broken specimens were collected after compressive strength testing was performed. All specimens were dried at 60 °C for 24 h and coated with gold prior to the examination under scanning electron microscope (SEM; JEOL JSM-5910LV) at accelerating voltages of 15 kV.

3. Results

3.1. Microbial calcite deposition in soil-cement interlocking block

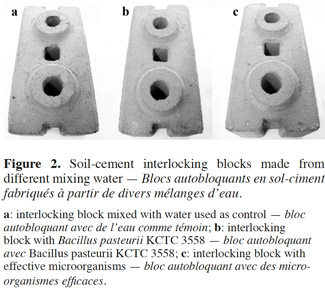

19There is no visible difference observed between soil-cement interlocking block samples made with different mixing water as shown in figure 2: interlocking block with tap water (a), interlocking block with B. pasteurii KCTC 3558 in urease production media (b) and interlocking block with urease production media + 5% (v/v) EM (c).

3.2. Compressive strength test

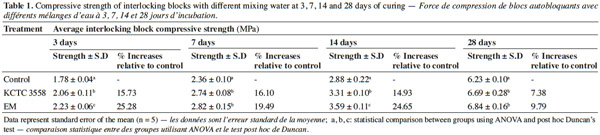

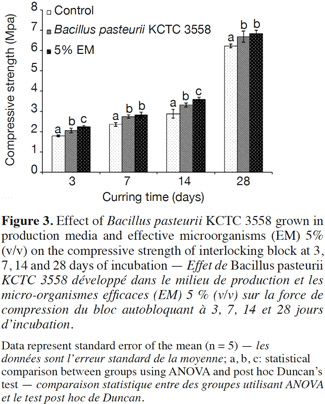

20The compressive strength of interlocking samples with different mixing water is summarized in table 1. The compressive strength was significantly increased for the interlocking block samples mixed with bacterial cells and 5% (v/v) EM compared to control. The overall trend of compressive strength was increasing and the highest compressive strength was achieved with interlocking blocks that were cured for 28 days. Interlocking blocks mixed with production media and B. pasteurii KCTC 3558 showed 7.38% (6.69 MPa) improvement in compressive strength compared with control (6.23 MPa) while compressive strength of those samples mixed with production media and 5% (v/v) EM was increased up to 9.79% (6.84 MPa) (Figure 3).

3.3. SEM analysis

21Calcite precipitation by B. pasteurii KCTC 3558 and EM in interlocking block specimens was visualized by SEM analysis. The growth of carbonate crystals was observed in the specimens that were prepared with B. pasteurii KCTC 3558 and EM as mixing water (Figure 4b-c). No carbonate crystal was observed in control which was conventionally prepared with tap water (Figure 4a).

4. Discussion

22The overall trend of compressive strength improvement up to 28 days of incubation is possibly due to the behavior of microbial cells within interlocking block. At the beginning of the incubation period, the growth condition might not be appropriate for the added microorganisms as most cells were still inactive due to the introduction to a new microenvironment. After the interlocking blocks were incubated, microbial cells gradually started to grow slowly. From the equation previously mentioned, urease was produced during the microbial growth to hydrolyze a molecule of urea and releases a molecule of carbonate ion and two molecules of ammonium ion (Qin et al., 2002). This microbial induced chemical reaction causes an increasing pH of its surrounding which leads to the precipitation of calcite when calcium ion exists in the environment (Mobley et al., 1989). As the microbial cells were introduced into interlocking block, pH within interlocking block matrix increased, with the presence of calcium ions in the culture medium added as mixing water, calcium carbonate precipitated. Thus, calcium carbonate precipitation can take place both on the cell surface and within soil-cement matrix. The pores in the matrix of interlocking block were then plugged up as suggested by Ramachandran et al., 2001; Ghosh et al., 2005 and Ramakrishnan et al., 2005.

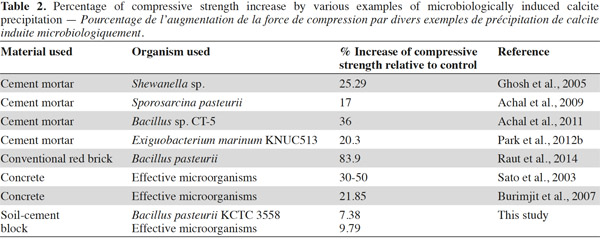

23The observed increase in compressive strength of interlocking block with B. pasteurii KCTC 3558 was in agreement with the results of previous reports which showed significantly increase in compressive strength of concrete and cement mortar (Ghosh et al., 2005; Jonkers, 2007; Achal et al., 2009; Achal et al., 2011; Park et al., 2012b) and brick (Raut et al., 2014) using microorganisms. In addition, EM was used as a mixture for concrete and found to have similar effect as air entraining and water reducing agent. The compressive strength of concrete treated with 5% (v/v) EM was increased compared to control (Sato et al., 2003; Burimjit et al., 2007) as summarized in table 2. It is evident from our results and previous studies that the increasing of compressive strength is mainly due to consolidation of the pores inside interlocking block with microbiologically induced calcium carbonate precipitation (MICP).

24Although an increasing compressive strength was observed in this study, this increase is lower than those earlier reported. It is likely that this difference is resulted from different types of microorganisms and culture media used in the experiments. The procedure used in deposition of microorganisms in specimens and the specimens curing process may also be possible reasons. Modified production media was used in this study due to its urease producing enhancement property and low cost. However, this modified production media is low in nutrients that may result in a lower growth rate and lower urease activity compared with those cultivation in rich media used in other reports such as nutrient broth, yeast extract broth, lactose mother liquor broth (Achal et al., 2009; Achal et al., 2011), tryptic soy broth (Park et al., 2012b) or an optimized urease production media (Raut et al., 2014).

25In this study, microbial cells were directly added into specimens after 24 h of cultivation without harvesting cell from growth medium which was different from the work of Park et al. (2012b) and Raut et al. (2014), where bacterial culture was harvested from growth medium and resuspended in phosphate buffer or saline before introduced into the specimens. In addition, the specimens in this study were cured under moist air condition following the standard interlocking block manufacturing process. No nutrient was added during this incubation period which could limit microbial growth and its metabolism therefore affected the compressive strength. In other reports, specimens were incubated in culture media (Achal et al., 2009; Achal et al., 2011; Park et al., 2012b; Raut et al., 2014), saturated with nutrients which microorganisms could use for their maximum growth and metabolism, resulted in a higher increase in compressive strength.

26For specimens with EM, the development of compressive strength is lower compared with those reported by Sato et al. (2003) and Burimjit et al. (2007). Although the specimens were all prepared with EM as mixing water, the improvements in compressive strength were different. One possible explanation may be due to the variation of microorganisms present in different batch of EM used in each study. Moreover, specimen compositions likely affected the compressive strength as demonstrated in specimens from Sato et al. (2003) and Burimjit et al. (2007) experiments which contain higher cement content (30.7% and 23.5% cement in whole components, respectively) than our specimens in which the major composition is soil (16.7% cement).

27Furthermore, calcium carbonate crystal growth of those specimens prepared with cell suspension of B. pasteurii KCTC 3558 and those prepared with 5% EM was found under scanning electron microscope indicated that the increase strength of interlocking block was essentially due to biocalcification by B. pasteurii KCTC 3558 and EM microorganisms. It can be inferred that biocalcification induced by B. pasteurii KCTC 3558 and EM performs an important role in improving interlocking block compressive strength.

5. Conclusions

28Based on the results of this study, it can be concluded that the addition of urease producing microorganisms has positive effect on compressive strength of interlocking block. Mixed bacterial culture in EM was found to be more effective in inducing calcite precipitation within interlocking block as seen by a 9.79% increase in the compressive strength of interlocking block compared to control. Microbiologically induced calcite precipitation or biocalcification could be applied to increase the compressive strength of interlocking block. However, further study on suitable culture media for interlocking block manufacturing is needed. The development of a more effective process for large scale production is also necessary for practical applications.

29Acknowledgements

30The financial support for this study was received from The Graduate School, Chiang Mai University and Faculty of Science, Chiang Mai University for budget year 2012 and 2013.

Bibliographie

Achal V., Mukherjee A., Basu P.C. & Reddy M.S., 2009. Lactose mother liquor as an alternative nutrient source for microbial concrete production by Sporosarcina pasteurii. J. Ind. Microbiol. Biotechnol., 36, 433-438.

Achal V., Mukherjee A. & Reddy M.S., 2011. Microbial concrete: a way to enhance the durability of building structures. J. Mater. Civ. Eng., 23, 730-734.

American Society for Testing and Materials, 2007. Standard test methods for sampling and testing brick and structural clay tile. American Society for Testing and Materials, Standard C 67-07. West Conshohocken, PA, USA: ASTM International.

Anand K.B. & Ramamurthy K., 2005. Development and evaluation of hollow concrete interlocking block masonry system. TMS J. , 23(1), 11-19.

Burimjit C. & Permsang-ngam P., 2007. Influence of effective microorganisms in concrete on compressive strength and life cycle assessment of EM-concrete. B. Engineering study problem. Chiang Mai, Thailand: Chiang Mai University, Department of Civil Engineering, Faculty of Engineering.

De Muynck W., De Belie N. & Verstraete W., 2007. Improvement of concrete durability with the aid of bacteria. In: Proceedings of the 1st International conference, Self healing materials, 18-20 April, 2007, Noordwijk aan Zee, The Netherlands, 1-10.

Douglas S. & Beveride T.J., 1998. Mineral formation by bacteria in natural microbial communities. FEMS Microbiol. Ecol., 26, 79-88.

Fujita Y. et al., 2000. Calcium carbonate precipitation by ureolytic subsurface bacteria. Geomicrobiol. J., 17, 305-318.

Ghosh P., Mandala S., Chattopadhyayb B.D. & Palc S., 2005. Use of microorganism to improve the strength of cement mortar. Cement Concrete Res., 35, 1980-1983.

Hammes F. & Verstraete W., 2002. Key roles of pH and calcium metabolism in microbial carbonate precipitation. Rev. Environ. Sci. Biotechnol., 1, 3-7.

Hammes F., Boon N., De Villiers J. & Verstraete W., 2003. Strain specific ureolytic microbial calcium carbonate precipitation. Appl. Environ. Microbiol., 69, 4901- 4909.

Hosokawa Y. et al., 2004. Recycling molten slag from waste to concrete products and construction materials in Japan. A case study report. In: Proceedings of the 29th Conference, Our world in concrete and structures, 25-26 August, 2004, Singapore, 289-296.

Jonkers H.M., 2007. Self healing concrete: a biological approach. In: Van der Zwaag S., ed. Self healing materials: an alternative approach to 20 centuries of materials science. Dordrecht, The Netherlands: Springer, 195-204.

Kokkhamheang W. & Rattanawong N., 2008. Interlocking block product from kaolinite top soil. In: Proceedings of the 13rd National convention on civil engineering, 14-16 May, 2008, Pattaya, Thailand, http://technologyblockprasan.com/download/file/009.pdf, (20/11/2013).

Mobley H.L. & Hausinger R.P., 1989. Microbial ureases: significance, regulation, and molecular characterization. Microbiol. Rev., 53, 85-108.

Park J.M., Park S.J., Kim W.J. & Ghim S.Y., 2012. Application of antifungal CFB to increase the durability of cement mortar. J. Microbiol. Biotechnol., 22(7), 1015-1020.

Park S.J., Chun W.Y., Kim W.J. & Ghim S.Y., 2012. Application of alkaliphilic biofilm-forming bacteria to improve compressive strength of cement-sand mortar. J. Microbiol. Biotechnol., 22(3), 385-389.

Qin Y. & Cabral J., 2002. Properties and applications of urease. Biocatal. Biotransform., 20, 1-14.

Ramachandran S.K., Ramakrishnan V. & Bang S.S., 2001. Remediation of concrete using microorganisms. ACI Mater. J., 9, 3-9.

Ramakrishnan V., Panchalan R.K. & Bang S.S., 2005. Improvement of concrete durability by bacterial mineral precipitation. In: Proceedings of the 11th International conference on fracture, 21-25 March, 2005, Turin, Italy.

Raut S.H., Sarode D.D. & Lele S.S., 2014. Biocalcification using B. pasteurii for strengthening brick masonry civil engineering structures. World J. Microbiol. Biotechnol., 30(1), 191-200.

Sarda D., Choonia H.S., Sarode D.D. & Lele S.S., 2009. Biocalcification by Bacillus pasteurii urease: a novel application. J. Ind. Microbiol. Biotechnol., 36, 1111-1115.

Sato N., Higa T., Sugita S. & Shuya M., 2003. Some properties of concrete mixed with effective microorganisms and the on-site investigation of the completed structures. In: Proceedings of the 28th International conference, Our world in concrete and structures, 28-29 August, 2003, Singapore.

Smith P.T., Douglas A.K.J. & Goodman N., 1993. Isolation and characterization of urease from Aspergillus niger. J. Gen. Microbiol., 139, 957-962.

Stocks-Fischer S., Galinat J.K. & Bang S.S., 1999. Microbiological precipitation of CaCO3. Soil Biol. Biochem., 31, 1563-1571.

Thailand’s Department of Industrial, 2012. Interlocking block production from industrial waste. In: Thailand’s department of industrial. Guidelines and eligibility of waste for processing into compressed charcoal fuel and interlocking block. Thung Phaya Thai, Rajadhevi, Bangkok, 56-73.

Thailand Institute of Scientific and Technical Research (TISTR), 1985. Using interlocking soil cement blocks. In: Proceedings of a National Training Workshop, 17-19 December, 1985, Bangkok, Thailand.