- Accueil

- Volume 20 (2016)

- Numéro 1

- Results of measurements of particulate matter concentrations inside a pig fattening facility

Visualisation(s): 0 (0 ULiège)

Téléchargement(s): 0 (0 ULiège)

Results of measurements of particulate matter concentrations inside a pig fattening facility

Notes de la rédaction

Received on September 15, 2014; accepted on November 12, 2015

Résumé

Résultats des mesures des concentrations en particules fines au sein d’une porcherie d’engraissement

Description du sujet. Cette note de recherche présente des résultats de mesures des concentrations en particules fines au sein d’une porcherie d’engraissement.

Objectifs. Les objectifs de la présente étude étaient de calculer des corrélations entre différentes classes de taille de particules fines (PM) relevées en porcherie d’engraissement et de comparer la taille des particules (PSD) au cours d’une période d'engraissement et en fonction de deux modalités de logement et de deux protocoles de nettoyage.

Méthode. Les données de deux périodes consécutives d'engraissement dans une porcherie commerciale ont été utilisées.

Résultats. Des corrélations très fortes ont été observées entre les concentrations intérieures de PM10 et PM2,5. En fonction de l'instrument de mesure, les corrélations de ces fractions avec PM1 étaient fortes ou faibles. Dans la présente étude, aucune différence de PSD n’a été trouvée entre les deux modes d’hébergement ni entre les deux protocoles de nettoyage.

Conclusions. Les résultats de cette étude montrent des corrélations très fortes entre les concentrations intérieures de PM10 et PM2,5. Dans la présente étude, aucune différence dans l’évolution de la taille des particules n’a été relevée.

Abstract

Description of the subject. This research note discusses the results of measurements of particulate matter concentrations inside a pig fattening facility.

Objectives. The objectives of the present study were to investigate the correlations between the different size fractions of indoor particulate matter (PM) inside a pig fattening facility and to investigate the evolution of particle size distribution (PSD) through a fattening period and between two housing systems and two cleaning protocols.

Method. Data from two consecutive fattening periods in a commercial pig barn were used.

Results. Very high correlations were found between PM10 and PM2.5 indoor concentrations. Depending on the measuring instrument, high or low correlations were found between PM1 and PM10 or PM2.5 indoor concentrations. No differences in PSD could be found between the two housing systems or the two cleaning protocols.

Conclusions. The results from the present study showed high correlations between the indoor concentrations of PM10 and PM2.5. In the present study, no differences in PSD were found.

Table des matières

1. Introduction

1Inside livestock barns, a wide variety of aerial pollutants, including particulate matter (PM), can affect indoor air quality (NRC, 2003). Unlike the chemically well-defined gaseous pollutants, PM is a mixture of many types of particles that differ in size, shape, chemical composition, and density (Pedersen et al., 2000). To cope with the heterogeneous nature of PM and the associated highly irregular shape and variety in density of the particles, the behavior of the different particles is commonly described by the aerodynamic diameter (AED). The AED of an irregularly shaped particle is defined as the diameter of a sphere with a standard density (1 000 kg·m-³) that would have the same settling velocity in air as the particle (Zhang, 2004). A wide range of particles with different AED can be found inside livestock houses (Harry, 1978). Particle size distribution (PSD) analysis may help to describe this heterogeneity in AED and is perhaps the most important physical parameter determining particle behavior.

2Therefore, the aims of the current study were to investigate the correlations between the different size fractions of indoor PM in a commercial fattening pig barn and to perform PSD analysis in order to get an overview of the dominant size ranges in fattening pig facilities.

2. Materials and methods

2.1. Experimental design

3The measurements were performed at one commercial fattening pig facility in Diksmuide, Belgium during two fattening periods. However, measurements were performed in two types of housing systems (conventional and low-ammonia-emission) and two cleaning protocols (dry and wet) were performed in order to increase the variation in PM concentrations. A detailed description of the housing systems and the cleaning protocols can be found in Ulens et al. (2014).

2.2. Measuring equipment

4Two spectrometers (Grimm 1.109, Grimm Aerosol Technik GmbH & Co. KG, Ainring, Germany) and two particle counters (Graywolf Particle Counters [GPCs] type Handheld 3016IAQ, GrayWolf Sensing Solutions, Shelton, CT, United States) were used to sample three PM fractions: PM10, PM2.5 and PM1. These fractions are defined as particulate matter which passes through a size-selective inlet with a 50% efficiency cut-off at 10 µm AED, 2.5 µm AED or 1 µm AED, respectively (U.S.EPA, 2004).

5Both the Grimm spectrometers and the GPCs make use of a laser diode light source. Scattered light is collected and focused onto a photo diode that converts the bursts of light into electrical pulses. The amplitude of the pulses is used as the measure of the particle size.

6More information about the measuring setup and characteristics of the different instruments can be found in Ulens et al. (2014).

2.3. Data analysis

7Correlations. Comparison of the data from the different housing systems and cleaning protocols revealed no significant differences in PM concentrations (Ulens et al., 2014). Therefore, all correlations were calculated based on the full dataset. The full dataset contained approximately 18 000 hourly means of PM concentrations. The Grimm spectrometer and GPC datasets contained both approximately 9 000 hourly mean PM concentrations.

8Correlations between the different PM fractions were calculated using SPSS Statistics 21.0 (SPSS Inc., Chicago, IL, USA) for the entire dataset and for the two subsets separately. Using the Kolmogorov-Smirnov test and based on visual inspection of QQ-plots, it was shown that the data were not normally distributed (p < 0.05). Therefore, Spearman’s rank correlation coefficients were calculated. All statistical tests were performed at 0.05 significance level.

9Particle Size Distribution (PSD). Only the data from the Grimm spectrometers were used. These spectrometers are capable of counting the number of particles in 31 size ranges with the following lower limits (µm): 0.25; 0.28; 0.30; 0.35; 0.40; 0.45; 0.50; 0.58; 0.65; 0.70; 0.80; 1.0; 1.3; 1.6; 2.0; 2.5; 3.0; 3.5; 4.0; 5.0; 6.5; 7.5; 8.5; 10.0; 12.5; 15.0; 17.5; 20; 25; 30; and 32. The 32 µm size range was not included in the analysis due to uncertainties about its upper limit. The Grimm spectrometers were used in two conventional and two low-ammonia-emission compartments. Both cleaning protocols were used in each type of housing system.

10To represent the PSD, the count median diameter (CMD) and the mass median diameter (MMD), together with their respective geometric standard deviation (GSD) were calculated, using equations adapted from Zhang (2004). Both diameters were calculated based upon the number of particles for the 30 size ranges of the Grimm spectrometers. For purposes of calculation we assumed that all particles were spherical and had the same density.

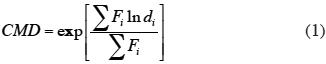

11The CMD (in µm) is defined as the geometric mean diameter of the number–weighted PSD. For a lognormal distribution, the geometric mean equals the median. The CMD was calculated using Equation 1:

12where Fi: number of particles per m³ in size range i, ∑Fi: total number of particles per m³, di: mean diameter of the lower and upper limit of size range i, in µm.

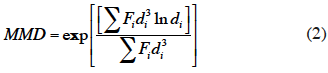

13The MMD (in µm) is defined as the diameter for which half the total mass of particles is larger and half is smaller than this size. The MMD was calculated using Equation 2:

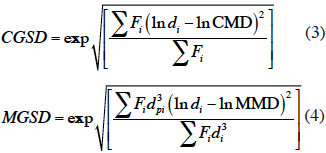

14The CGSD and MGSD are dimensionless quantities with a value greater than 1.0 and are a measure for the width of the number-weighted or mass-weighted aerodynamic particle size distribution. The CGSD for the number-weighted PSD was calculated using Equation 3 and the MGSD was calculated using Equation 4:

15CMD, MMD, and their respective GSD were calculated on hourly data from the two consecutive fattening periods in the four compartments. These calculations were automated in R3.0.1 (R Core Team, 2013).

3. Results and discussion

3.1. Correlations between different particulate matter size fractions

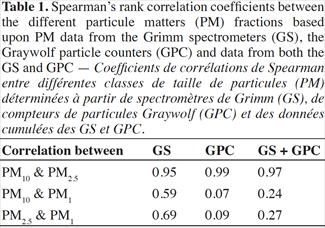

16Very high correlations (R > 0.95) were found between PM10 and PM2.5 when analyzing data from both the Grimm spectrometers and GPCs (Table 1). The observed high correlations between PM10 and PM2.5 indoor concentrations were also found by Van Ransbeeck et al. (2013) inside livestock buildings and by Marcazzan et al. (2001) in ambient air. This can partially be explained by the fact that PM2.5 is a substantial part of PM10. Nevertheless, in the current study the mean ratio PM10:PM2.5 was about 10:1, while Marcazzan et al. (2001) found a ratio of 3:2 in ambient air. Most of the PM inside livestock buildings is primary in origin and can mainly be found in the coarse (PM10-PM2.5) fraction. This is especially the case for PM originating from feed, animal hair, and skin as well as manure (Cambra-López et al., 2011). Particles in the fine (PM2.5) fraction are mostly formed through chemical reactions between gases and particles. These secondary processes occur to a lesser extent inside livestock buildings and part of the mechanically generated particles can fall into the PM2.5 size range (Cambra-López et al., 2010).

17Lower correlations (R < 0.4) were found between PM10 and PM1 and between PM2.5 and PM1 when analyzing the data from both measuring instruments together and from the GPCs (Table 1). However, higher correlations (R > 0.5) between PM10 and PM1 and between PM2.5 and PM1 were found when analyzing the data from the Grimm spectrometers (Table 1). Using the same Grimm spectrometers, Van Ransbeeck et al. (2013) found a high correlation between PM2.5 and PM1 indoor concentrations (R = 0.77) and a lower correlation between PM10 and PM1 indoor concentrations (R = 0.46). However, when using the GPCs, correlations were much lower in our study. This indicates that the observed correlations with PM1 are dependent upon the measuring instrument used. However, both instruments claim a counting efficiency of 50% at AED of 0.3 µm and of 100% for all particles larger than 0.45 µm (manufacturer’s website; Schmoll et al., 2010). The relative humidity inside the stable can also play an important role. At high relative humidity, water molecules risk of being recognized as particles by the optical instrumentation which can falsify the measurements. To overcome this problem, the Grimm spectrometers are equipped with an air mixing device which can add particle-free dry air to the sample airflow. This system is activated when the relative humidity exceeds 85% (manual Grimm spectrometer). The GPCs however are not equipped with such a device and therefore do not correct for high relative humidity.

3.2. Particle size distribution

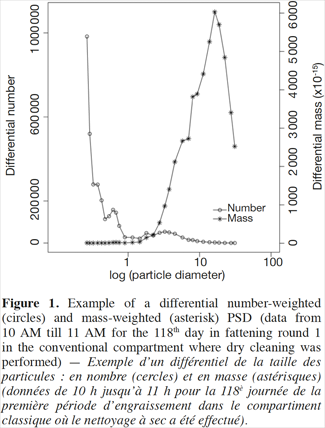

18Figure 1 shows a typical example of the differential number-weighted and differential mass-weighted particle size distribution in the pig barn. It can be seen that the smallest particle sizes (< 1 µm) are highest in number, whereas the highest mass-weighted fractions occur near 10 µm. Few differences were found between the mean CMD values for the different compartments and fattening periods with values ranging from 0.43 to 0.49 µm. These values are similar to the value (0.40 µm) found by Lai et al. (2012) who analyzed the PSD in different pig buildings using identical Grimm spectrometers. The mean MMD values, ranging from 10.73 to 12.18 µm, found in the current study correspond well with values found by Maghirang et al. (1997) in a pig nursery (ranging from 10 to 19 µm) using a cascade impactor. The GSD values found in the current study for the number- and mass-weighted distribution were all larger than 1.22, indicating that the aerosols in all compartments were polydisperse.

19Despite the different housing systems and cleaning protocols observed in this study, very similar PSDs were found. However, as reported previously (Ulens et al., 2014), indoor mass concentrations of PM10, PM2.5, and PM1 changed throughout the fattening periods. Furthermore, the lack of a clear pattern over a day (data not shown) or over a fattening period (data not shown) is in contrast with the observed diurnal pattern and day to day pattern during a fattening period found for PM10, PM2.5, and PM1 concentrations (Van Ransbeeck et al., 2012). This indicates that, although the total mass of particles (PM concentrations) changed significantly (during a day and during a fattening period) inside the barn, the CMD and MMD values remained about the same.

4. Conclusions

20The results from the present study showed high correlations between the indoor concentrations of PM10 and PM2.5. No differences in PSD could be found between different housing systems or cleaning protocols.

Bibliographie

Cambra-López M. et al., 2010. Airborne particulate matter from livestock production systems: a review of an air pollution problem. Environ. Pollut., 158(1), 1-17.

Cambra-López M., Torres A.G., Aarnink A.J.A. & Ogink N.W.M., 2011. Source analysis of fine and coarse particulate matter from livestock houses. Atmos. Environ., 45(3), 694-707.

Harry E.G., 1978. Air pollution in farm buildings and methods of control: a review. Avian Pathol., 7(4), 441-454.

Lai H.T. et al., 2012. Airborne particles in animal houses. In: Cambra-López M. et al., eds. Proceedings of the The Ninth International Livestock Environment Symposium (ILES IX), 8-12 July 2012, Valencia, Spain. St Joseph, Michigan, USA: American Society of Agricultural and Biological Engineers, C1769.

Maghirang R.G., Puma M.C., Liu Y. & Clark P., 1997. Dust concentrations and particle size distribution in an enclosed swine nursery. Trans. ASAE, 40(3), 749-754.

Marcazzan G.M., Vaccaro S., Valli G. & Vecchi R., 2001. Characterisation of PM10 and PM2.5 particulate matter in the ambient air of Milan (Italy). Atmos. Environ., 35(27), 4639-4650.

NRC, 2003. Air emissions from animal feeding operations: current knowledge, future needs. Washington, DC: The National Academies Press.

Pedersen S. et al., 2000. Dust in pig buildings. J. Agric. Saf. Health, 6(4), 261-274.

R Core Team, 2013. R: a language and environment for statistical computing. Vienna: R Foundation for Statistical Computing.

Schmoll L.H., Peters T.M. & O'Shaughnessy P.T., 2010. Use of a condensation particle counter and an optical particle counter to assess the number concentration of engineered nanoparticles. J. Occup. Environ. Hyg., 7(9), 535-545.

U.S.EPA, 2004. Air quality criteria for particulate matter (final report, Oct 2004). Washington, DC: U.S. Environmental Protection Agency, EPA 600/P-99/002aF-bF, 2004.

Ulens T. et al., 2014. The effect of different pen cleaning techniques and housing systems on indoor concentrations of particulate matter, ammonia and greenhouse gases (CO2, CH4, N2O). Livest. Sci., 159(0), 123-132.

Van Ransbeeck N. et al., 2012. Typical indoor concentrations and emission rates of particulate matter at building level: a case study to setup a measuring strategy for pig fattening facilities. Biosyst. Eng., 111(3), 280-289.

Van Ransbeeck N., Van Langenhove H. & Demeyer P., 2013. Indoor concentrations and emissions factors of particulate matter, ammonia and greenhouse gases for pig fattening facilities. Biosyst. Eng., 116(4), 518-528.

Zhang Y., 2004. Indoor air quality engineering. Boca Raton, FL, USA: CRC Press.