- Accueil

- Volume 26 (2022)

- Numéro 3

- Modeling aquaponics: a review on available models and simulation tools

Visualisation(s): 0 (0 ULiège)

Téléchargement(s): 0 (0 ULiège)

Modeling aquaponics: a review on available models and simulation tools

Document(s) associé(s)

Version PDF originaleRésumé

Synthèse bibliographique des outils de modélisation disponibles pour l’aquaponie et identification des besoins actuels

Introduction. Le domaine de l’aquaponie se développe rapidement et de nombreux modèles et outils de modélisation spécifiques ont été développés. Cependant, à ce jour, aucun projet n’a tenté d’unir la communauté aquaponique autour d’un projet de modélisation commun, afin de centraliser les connaissances et développer un outil performant à portée des utilisateurs et des professionnels.

Littérature. Cet article établit la synthèse bibliographique de la littérature pertinente afin de générer une vue d’ensemble des modèles et outils de modélisation disponibles pour l’aquaponie. Cette synthèse tend aussi à identifier les besoins actuels du secteur en outils de modélisation afin d’orienter de futurs développements.

Conclusions. Plusieurs modèles et outils de modélisations performants ont été publiés et présentés. Cependant, ces derniers sont spécifiques à leur cadre de recherche et ne sont souvent pas accessibles. La connaissance relative à la modélisation de l’aquaponie a atteint un stade de maturité avancé mais elle reste dispersée au sein de nombreux travaux différents. Un outil de modélisation partagé et accessible fait défaut et pourrait aider à accélérer significativement le développement de l’aquaponie.

Abstract

Introduction. Aquaponics is quickly expanding. Specific models and modeling tools have been developed within different studies. However, no study has yet attempted nor succeeded in bringing the aquaponic community around a common modeling project to centralize knowledge and develop an effective tool for users and professional growers.

Literature. This paper reviews the relevant literature to provide an overview of the available simulation models and associated modeling tools. Furthermore, it identifies the current needs to lead further modeling developments.

Conclusions. Several powerful models and modeling tools have been developed but are highly specific to their research scope and are often inaccessible. The modeling knowledge specific to aquaponics is at an advanced stage but is scattered among many different works. Therefore, it is evident that a shared and accessible modeling tool, which is currently missing, would greatly accelerate the development of aquaponics.

Table des matières

Received 25 October 2021, accepted 6 September 2022, available online 15 September 2022.

This article is distributed under the terms and conditions of the CC-BY License (http://creativecommons.org/licenses/by/4.0)

1. Introduction

1Aquaponics is a production method that combines fish and plant farming in a common system by taking advantage of the mineralization of nutrients carried out by microorganisms. The use of biological methods as treatments to increase water efficiency of closed fish production systems has been studied since the early 1970s. Naegel (1977) first proposed hydroponics as a way of achieving higher yields while reducing water usage of recirculated aquaculture. It was demonstrated that the addition of soilless plant culture was an efficient method to purify water of intensified fish culture and it began to rapidly gain interest (Nelson et al., 1990). The name aquaponics was later given to the discipline that allows to grow higher amounts of food by integrating vegetable hydroponics with fish culture in recirculating systems (Rakocy, 1994).

2The number of research papers dedicated to aquaponics started to grow rapidly from 2010 (Hao et al., 2020). However, the number of related papers was still relatively low with only 35 papers published on the subject in 2015. In comparison, the number of publications on hydroponics for the same year was around 800 papers. The hype ratio, which is an index of popularity of a subject, was ten times higher in 2017 for aquaponics than it was for hydroponics (Junge et al., 2017). These values show that there is a real interest for aquaponics but that research is still lacking. This creates a gap between the available knowledge and the needs.

3This review focuses on simulation models for aquaponics. Simulation or mathematical models are helpful in developing knowledge for biological systems. Mathematical models are abstractions of systems that capitalize on the ever-growing amount of data to generate useful tools. Modeling has become an essential tool in agricultural systems sciences and engineering. Computational models can accelerate the development of research areas by allowing the simulation of high numbers of experiments in short amounts of time (Jones et al., 2016). Therefore, modeling aquaponics can be seen as a solution to rapidly generate knowledge and reduce the gap with the needs. Modeling is seen as an essential tool in a wide range of modern agricultural disciplines, thanks to the rapid and continuous growth of computing power (Jones et al., 2016).

4This paper reviews the current available simulation models and modeling tools for aquaponics. It aims to identify the current needs of users and the development challenges that need to be addressed in the future. This paper does not review simulation models developed specifically for aquaculture or hydroponics. It aims at screening modeling studies developed for aquaponics. From this perspective, the research questions to be addressed in this review are:

5– what simulation models have been developed for aquaponics?

6– what were the research objectives addressed by those simulation models?

7– are the modeling tools associated with these simulation models available for use?

8– is there a need for the development of new modeling tools?

2. Research methodology

9The analysis is based on a comprehensive literature review of models and modeling tools for aquaponics. The objective of this research is to synthesize the current knowledge and approaches on modeling aquaponic systems. The systematic analysis presented in this paper is based on a qualitative analysis of carefully selected research, conference papers and books. The task was performed manually, and the identified articles were reviewed and categorized based on their research focus and results. The systematic review is carried out to provide a comprehensive view of existing research with the purpose of identifying potential gaps in the field and lead to future research.

10As a first step, the literature was surveyed within an undefined timeframe to gather as many results as possible for this relatively young topic. Only the publications written in English were considered. A combination of keywords was established to address both the aquaponics and the modeling side of the research questions. The search equation was built on a combination of several possible terms to encompass as many spellings and sources as possible (i.e. “model*”, “modeling framework”, “computer model”, “numerical model”, “computational model”, “mathematical model”, “predict*”, “dynamic*”, “digital twin”, “simulation*”, “process*”, “ecological”, “biosystem*”, “aquaponic*”, “aquaculture and hydroponics”, “plants and fish”). Two bibliographical databases were searched, Scopus and Google Scholar, using a combination of the keywords. Scopus was selected for its wide coverage of relevant literature and advanced search features while Google Scholar allowed to widen the search and add a few relevant results. From these two databases, 943 raw results were retrieved. Additionally, the results were filtered using the advanced tools of the databases and were sorted manually based on titles and abstracts for relevance. As a result, 31 sources were considered relevant. A ‘snowballing’ search was also conducted based on the references of the 31 sources and allowed to retrieve 14 additional sources. This global search process resulted in 26 peer-reviewed articles, eight master thesis, seven conference proceedings articles, two doctoral thesis, one book chapter and one project report.

11As a second step, the selected literature was analyzed, and the sources were classified and summarized. First, the results went through an additional screening to remove unreliable sources and to keep only numerical and statistical models developed for simulations, predictions, or dimensioning purposes. Therefore, abstract models for case studies were removed from this review as the aim is to identify the current state of mathematical tools for aquaponics. The additional screening resulted in a list of 28 sources containing 24 peer-reviewed articles, three conference proceedings articles and one book chapter.

12For each study, we analyzed the presented models and the associated simulation tool when it was provided. Models contain mathematical constructs such as equations and methodologies while modeling tools are software structures that contain models and provide access for models use, without the need for additional coding (Atkinson & Kühne, 2005).

3. Results

13Results show that new mathematical concepts were not invented for aquaponic models. Instead, aquaponic models originated from the integration of existing knowledge from other specific fields such as aquaculture, hydroponics and general modeling mathematics. The results of these models show that aquaponic systems are synergic systems that lead to beneficial results in terms of energy consumption, water use and nutrients consumption (Körner et al., 2021). Every model integrates the knowledge differently and tries to demonstrate one or several synergic effects of the system. Additionally, the models fall within research initiatives that have limited life-spans. The modeling effort is scattered and discontinuous.

14This paper does not study or present the equations used within the models. Instead, this paper studies the integration efforts, compares studies on the basis of their development scopes and purposes and highlights the general timeline of the development of modeling aquaponics.

15Mathematically, the identified aquaponic models range from simple simulation models to complex process-based and agent-based models. The properties show a lot of variability from models that use empirical, mechanistic, stochastic or numerical approaches to models that use machine learning methods. Simpler models are made of sets of few equations and focus on specific parts of the system while more complex models gather larger sets of equations to describe the operations of each subsystem of the whole aquaponic ecosystem.

3.1. Models overview

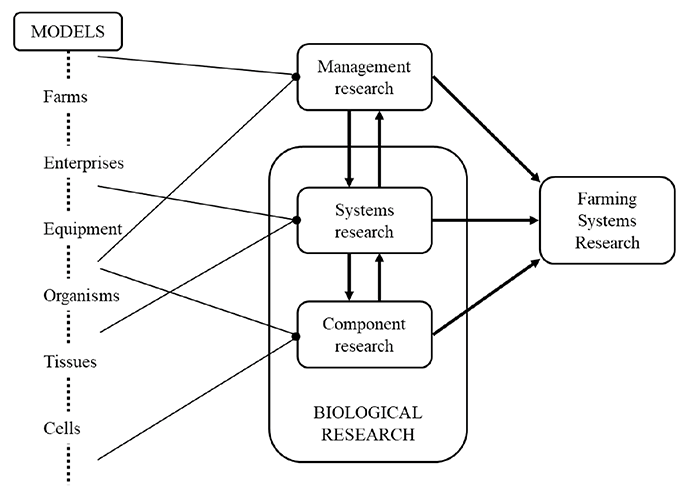

16Cacho (1997) proposed a classification for the aquaculture modeling research in relation to the produced models. For this review, the diagram was adapted for aquaponics (Figure 1). The research was classified in three categories:

17– “Component research” that focuses on modeling one or several components of the aquaponic system;

18– “System research” that focuses on modeling the whole aquaponic system;

19– “Management research” that focuses on building integrated tools at the scale of entire farm.

Figure 1. Relationship between different types of research and the types of models produced — Relations existantes entre le type de recherche et les types de modèles développés.

Figure 1. Relationship between different types of research and the types of models produced — Relations existantes entre le type de recherche et les types de modèles développés.

20Most of the research fall under the “Biological Research” super category which includes the system and the component research, as they developed models for the entire aquaponic system or parts of the system. However, a few other studies belong to the “Management research” category as they focus on very specific topics such as developing tools based on image analysis, increase the efficiency of measurements through modeling, building manufacturing execution systems (MES) or digital twins for aquaponics. The higher-level category “Farming systems research” uses a systems approach to integrate information from physical, biological and social sciences. It places emphasis on the farmer, not only as a decision maker, but also as a “social being” who is part of a community and has goals other than profit maximization. Since the research analyzed for this review is directed towards the development of models and technical tools, no research fell into this category as the social dimension was mostly or totally left out.

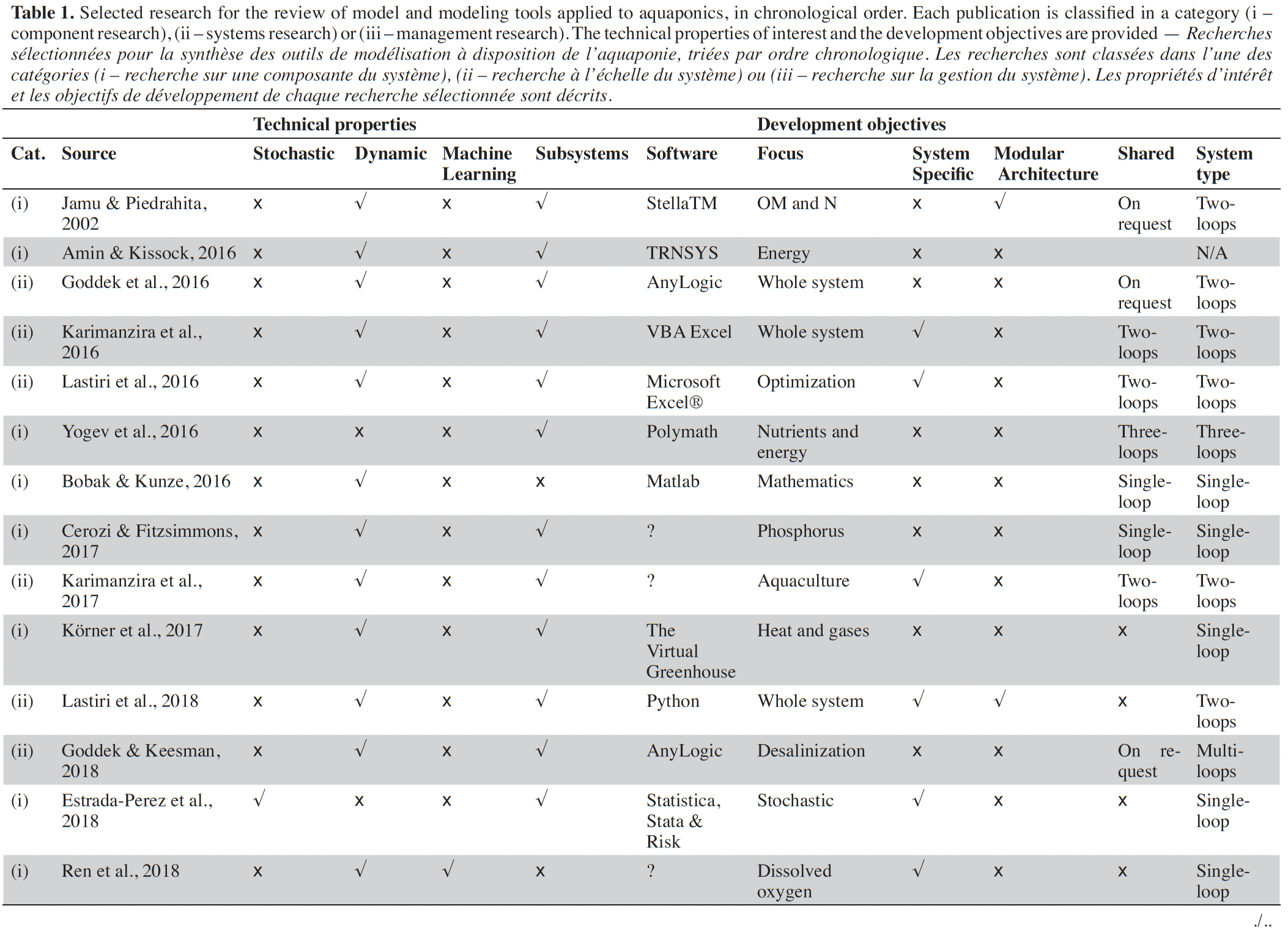

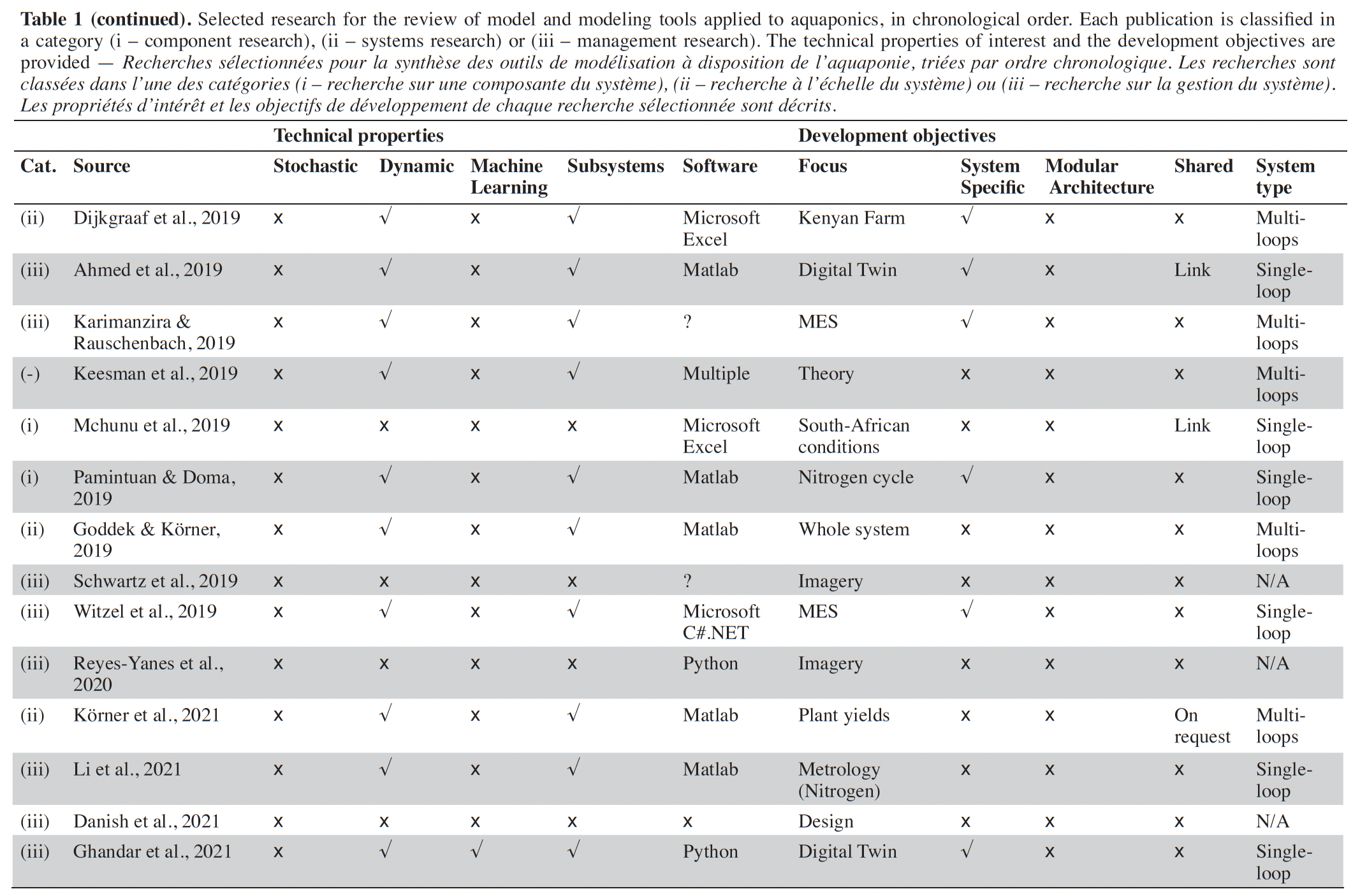

21Table 1 presents a chronological review of research papers that provide models and modeling tools specific to aquaponics. The technical properties of interest of each model and the development objectives of the associated research are provided.

22Most papers provide a model that is numerical and dynamical. They describe the aquaponics system as an association of several subsystems. This approach provides an opportunity to study the dynamic behavior of specific parts of the system.

23Half of the models are system specific. They were developed and tested in association with a specific experimental set-up. Two studies (Jamu & Piedrahita, 2002; Lastiri et al., 2018) highlight the modularity of the produced model instead of focusing on a single system architecture. Finally, out of the 28 selected studies, two provide a direct link to the developed tool, four mention a possible access on request and the 22 remaining studies do not put forward an intent of sharing.

3.2. Current state of aquaponic models

24The development of simulation models dedicated to aquaponics started from the association of well-developed modeling knowledge from aquacultural and agricultural sciences. Jamu & Piedrahita (2002) were the first to make that association and propose a mass balance model for coupling the outputs of ponds aquaculture with conventional soil agriculture. The purpose of their model is to predict the production rate of organic matter produced from aquaculture ponds to couple the system with conventional agricultural practices accurately.

25More recently, other models were developed specifically for aquaponics, which mostly became the combination of aquacultural practices and hydroponics. Therefore, these models focus on merging aquaculture and hydroponics mathematics, using knowledge from both fields and establishing aquaponic-specific values for the parameters of the models. The models are mostly designed for specific research objectives and differ in structure and content.

26Keesman et al. (2019) wrote a book chapter that includes a broad overview of the “good practices” for modeling aquaponics. It addresses the basis of biological systems modeling. It also provides equations along with their associated numerical resolutions for different parts of the aquaponic system. The book chapter is an introduction to theoretical concepts of modeling aquaponics but is not intended to answer a research question. It was therefore not classified in any of the categories below as it does not provide an original modeling approach. However, the chapter is a valuable source of modeling knowledge.

27As mentioned above, the modeling works can be separated into three categories associated with the modeling of different parts of the aquaponic system. The three categories are:

28– component research;

29– system research;

30– management research.

31Most models focus on modeling a specific part of the system (component research) or the entire aquaponic ecosystem (system research).

32Component research. Component research includes the development of simulation models for a specific component of the system. We also included the research that focuses on applying an original modeling approach to aquaponics in this category. Indeed, these studies are rather specific and do not intend to study the system as a whole nor provide management tools.

33Amin & Kissock (2016) focused on building an energy model for greenhouses containing large bodies of water to simulate the effect of fish tanks in greenhouses. They showed that the tanks could help reducing the need for conventional cooling and heating systems. Similarly, Körner et al. (2017) designed an aquaponic extension for The Virtual GreenhouseTM simulator. It allowed them to study the influence of the aquaculture unit on the greenhouse climate through heat and gases exchanges. The simulation showed that an increase in water temperature of the aquaculture tanks results in an increase in metabolic activity and generates energy savings from a decrease in greenhouse heating. The developed model can be useful for climate control planning in aquaponics greenhouses. Cerozi & Fitzsimmons (2017) built a mass balance model specifically for phosphorus in aquaponics. It describes the interactions of the nutrient with fish and plants. The model successfully simulated phosphorus dynamics and can therefore be used as a tool to determine a fish to plants ratio for optimal phosphorus utilization. Oxygen is essential in aquaponic systems and can be the cause of important losses if not well managed. However, the concentration of dissolved oxygen can hardly be predicted using traditional prediction methods as many factors influence its equilibrium. Ren et al. (2018) built a functional model using neural networks to predict the concentration of dissolved oxygen and improve oxygen management. Mchunu et al. (2019) presented a static model to dimension aquaponic installations for South-African conditions. This model uses empirical equations calibrated on South-African data within an accessible dimensioning tool for growers. Pamintuan & Doma (2019) focused on the growth of fish, plants and bacteria and their interactions with nitrogen. They produced a model that assesses the nitrogen cycle in a constant-head, one pump aquaponic system. Finally, Schwartz et al. (2019) ran an experiment to develop predictive equations for root surface area of lettuces which is linked to the nitrification rate induced by the plants activity. Their aim is to complement current models and offer a more accurate way of dimensioning aquaponic systems. The modeling works presented above successfully provide a mathematical description of a specific component of the aquaponic system.

34Other papers focus on providing innovative modeling approaches for aquaponics. Estrada-Perez et al. (2018) showed that variability should be considered when designing models for aquaponics to better manage financial risks. They adopted a bioeconomic approach and created a stochastic and static model for aquaponics that successfully grasps the sources of variability on final yields. Yogev et al. (2016) developed a conceptual model for a three loops, off grid aquaponic system. Their model is a static model based on mass and energy balances. It allows the study of mass and energy flows between components of the system when it reaches a steady state. This model provides a way to quickly study the effects of a change in parameters on the mass and the energy distributions of the whole system at steady state. Finally, Bobak & Kunze (2016) further investigated the mathematical representation and resolution of the aquaponic system. They built the Jacobian matrix of a general aquaponic system, based on four state variables and nine parameters. The problem is then solved using a search for equilibrium states of the matrix. This highly theoretical view of the aquaponic system enables the easy identification of the most sensible parameters of the system. Future research should mainly focus on optimizing these sensible parameters as small variations in these parameters impact the aquaponic system the most. These three studies do not provide dynamic models but focus on developing different approaches for modeling aquaponics numerically. Their results are useful for further modeling developments as they contain valuable mathematical constructs and parameter values.

35Models associated with component research focus on specific components of the aquaponic system or on innovative modeling approaches. The research objectives are often well defined, and the resulting models are relatively simple and made of few equations. These models generate satisfying results and therefore fulfill their research objectives.

36System research. System research develops models that focus on the whole aquaponic system. Several studies fall under this category and come from two identified larger sets of works. The INAPRO project (“Innovative Aquaponics for Professional Application”) is an EU-funded project that focuses on a specific system architecture called the ASTAF-PRO (“Aquaponic System for emission-free Tomato and Fish Production”). Several research papers focus on modeling this specific system. Karimanzira et al. (2016) built a dynamic model of the system with the aim of implementation within a control system. They modeled most parts of the system using differential equations. Lastiri et al. (2016) also developed a complete dynamical model for the INAPRO aquaponic system, with the specific aim of reducing water, energy and nitrogen consumptions of the system. Karimanzira et al. (2017) focused on developing an optimization framework based on dynamical modeling of the aquaculture component for the production of fish of the INAPRO aquaponic system. Finally, Lastiri et al. (2018) proposed a modular approach for modeling aquaponic systems. They divided the aquaponic systems into different types of tanks (fish tank, settling tank, pump sump, biofilter, post purge, mixing tank and plant tank) and established the mass balance of each tank. They calibrated each basic simulated component on data generated by the INAPRO aquaponic system and associated these components to model the whole corresponding system. The resulting model gives highly accurate results and reliable simulations for the basic components of their specific system.

37Another integrated modeling work was carried out by Goddek et al. (2016) who first developed a model on Anylogic to simulate mass fluxes, while using a simple crop evapotranspiration model. The model was used to prove the necessity of using desalinization technology in aquaponics (Goddek & Keesman, 2018). A greenhouse model was then added to complete the original work and the resulting model showed the significant effect of local climate on evapotranspiration rates and consequently on sub-systems sizing (Goddek & Körner, 2019). This version of the model can be used for complete analysis of aquaponics combined with greenhouse hydroponics. Körner et al. (2021) used it to generate plant yields, which were missing to conduct a full life cycle analysis for an environmental impact assessment study of a multi-loop aquaponic system in an urban context. Similarly, Dijkgraaf et al. (2019) adapted the modeling work of Goddek et al. (2016) for a Kenyan aquaponic farm and added a digester tank component.

38The works on the INAPRO aquaponic system and the works based on the model developed by Goddek et al. (2016) both provide comprehensive dynamical and mechanical models for each component of the aquaponic system. They consider the whole system as a combination of its components. They are currently the most advanced modeling works for aquaponic systems as they provide accurate simulations for the biological (fish, plants and microorganisms), physical (energy and mass fluxes) and chemical (nutrients) components of aquaponics.

39Management research. Management research studies agricultural systems at the scale of the farm integrated into its social and business environments. Management research also contains equipment developed to help with the management of the production system and therefore includes research that presents the development of integrated tools with predictive capacities.

40Monitoring parameters of a production system is essential for growers as continuous monitoring can help anticipate financial returns and prevent significant losses. Reyes-Yanes et al. (2020) identified a lack of intelligent real-time approaches to monitor and track plant growth in aquaponics, which is hindering the transition towards automation and commercialization. They developed a model to estimate the mass of aquaponics lettuces using imaging and deep learning techniques. The estimated mass can be used in a feedback loop of a predictive algorithm to improve the reliability of predicted yields. Monitoring nitrogen concentrations is also essential in aquaponics. However, nitrogen sensors are often expensive or unreliable. Li et al. (2021) developed a method to continuously estimate and predict the nitrogen concentration of aquaponic systems by integrating mechanistic models, online measurements, and infrequent offline measurement of total nitrogen.

41Danish et al. (2021) proposed a conceptual forefront framework to enable interested parties to correctly model and design their aquaponic projects. They conclude that several emerging interdisciplinary practices should be used and combined. According to the framework, modeling the complex interlinked factors of aquaponics is a vital part of designing successful aquaponic projects. However, they do not point to a specific modeling approach.

42Digital twins are virtual representations of a physical object or process which are used for management and optimization. The virtual object or process is linked to its real-world counterpart through sets of sensors. Digital twins provide virtual representations updated in real-time and they often come with simulation functionalities. Ahmed et al. (2019) describe the implementation and validation of a small-scale physical aquaponic system linked to a corresponding digital twin using the internet of things (“IoT”). A simple mathematical model uses the readings from the sensors to predict fish and plants growth, nitrates concentration, water pH and total dissolved solids. Ghandar et al. (2021) further investigated the application of digital twins for aquaponics. They implemented machine learning predictions and mechanical model-based predictions in a common digital twin framework to compare both prediction methods with the measurements. The model-based approach gave better results since they did not have enough data to sufficiently train the machine learning algorithms. They conclude that a data driven approach of re-calibrating and updating the mechanical model might be the most effective method for aquaponics in a context of limited available data.

43Manufacturing Execution Systems (“MES”) are control and driving systems for production chains. MES are software solutions made of hardware and software components. Their goals are to monitor and manage complex production chains. Witzel et al. (2019) integrated the modeling works developed for the INAPRO aquaponic system (Karimanzira et al., 2016; Lastiri et al., 2016; Karimanzira et al., 2017) into a MES dedicated to the specific research system. Their MES supports and advices the aquaponic managers through a graphical interface which also provides simulated outputs and economic indicators. Karimanzira & Rauschenbach (2019) presented the benefits of integrating the involved MES into a complete automation system. They used cloud-based IoT-based predictive analytics to dynamically model state variables such as fish growth and nutrients concentrations. The MES can plan productions using economical optimization and can predict the times of maintenance.

44Management research of aquaponics tends to provide users such as researchers and growers with useful tools. These tools ultimately attempt to make the life of users easier by helping them make informed decisions based on accurate and reliable data. The available tools for aquaponics range from model-improved data acquisition chains to complete automated manufacturing execution system (“MES”).

3.3. Accessibility and extendibility of the modeling tools

45Out of the 28 models presented in table 1, the source code of four models can be accessed by request (Jamu & Piedrahita, 2002; Goddek et al., 2016; Goddek & Keesman, 2018; Körner et al., 2021) and two modeling tools can be downloaded directly. Ahmed et al. (2019) developed a digital twin on Matlab for aquaponics called AquaponicSim with simulation modules for fish and plants growth, dissolved solids, water acidity and nitrates concentration. However, the source code is specific to the small-sized system used for the experiment. It is a simplified model used mostly for the demonstration of the digital twin. Mchunu et al. (2019) created a modeling tool to provide South-African aquaponic growers with a tool adapted to the specific conditions of South-Africa. The tool consists of a set of empirical relationships designed to help growers dimension systems based on few inputs. These mathematical relationships were established from data collected by a large and local survey. The tool was implemented as a Microsoft Excel sheet to provide an accessible tool. The tool is not a dynamic model but is a useful dimensioning tool for local growers. It is therefore not adapted for aquaponic systems in other locations and cannot be used to predict dynamic behaviors.

46While aquaponics has known major developments, additional research is still required on the social, environmental, biological, and technological sides. According to Junge et al. (2017), efforts have yet to be made on the development of relevant sensors, on data analysis and modeling and on the development of automation. Evidence from advanced fields of agriculture shows that gathering models is crucial to centralize information, unify the communities, develop tools, and increase knowledge on the subject (Jones et al., 2016). However, aquaponics still lacks specialized tools and remains scarce among growers and professionals (Danish et al., 2021).

47Current aquaponics models succeed in meeting the research objectives of specific systems. However, they fail in their ability to adapt to other systems (Hao et al., 2020). The models presented in this study show different objectives for modeling the aquaponic ecosystem. While they focus on certain relevant aspects, they also neglect others through strong assumptions. Amin & Kissock (2016) created a model to study the temperatures in an energy-efficient aquaponic greenhouse but did not include the biological components. They concluded that economic factors should be included in a complete model. Goddek et al. (2016) presented an exhaustive aquaponic model, describing most components of the system. However, they indicated that future research should also include economic factors, the concentration of more dissolved nutrients, many fish and plant species and their associated specific nutritional needs. Cerozi & Fitzsimmons (2017) built a mass balance model around the phosphorus dynamics of aquaponic systems. They also concluded that the effort should be extrapolated to other essential nutrients. Bobak & Kunze (2016) provided a simple and elegant model but concluded that the model might oversimplify the system. The modeling work regarding the INAPRO aquaponic system reached an advanced stage and covers most parts of their research system. However, the model is highly system specific. They suggest that further modeling work should focus on adding the modeling of more nutrients (Lastiri et al., 2016) and that the flexibility of the model should be improved by increasing the modularity of each component (Lastiri et al., 2018). Additionally, they assume an ideal growth for plants and fish and advise that the results should be treated with caution because of that assumption.

48As stated by Goddek et al. (2019), the modeling of entire aquaponic systems under a wide range of management conditions would significantly improve the understanding of aquaponics, allow the study of different aquaponics configurations and lead future research to improve aquaponics. However, current tools entail closed software environments that can only be used by the developers. There is no common basis for model sharing and collaborative model development.

49The understanding of aquaponics grew considerably, and valuable efforts have been made to model the system and its components. However, the knowledge is currently distributed between various researchers and tools. Most importantly, these tools are not made available nor accessible to the public and the professionals. It is clear that a shared and accessible modeling tool is missing and could greatly help researchers and growers. The tool should focus on gathering the available knowledge, on merging the accessible works in a common environment and on providing a highly modular modeling architecture while generating a user-friendly access. A modular approach would allow the modeling of many system architectures and widen the scope of the tool. Aquaponics include several disciplines such as mass and energy exchanges, plants and fish sciences, microbiology, automation and economics among others. Such a tool could therefore be used by scientists, producers, and teachers. A modular tool would build up interest for users from these different backgrounds as they could use the tool for specific or mixed works.

4. Conclusions

50Several predictive models related to aquaponics have been presented in the past six years. The research evolved from a need to understand and optimize specific components of the system to fully agent-based and system-specific complex models. Currently, a valuable amount of knowledge is available for modeling aquaponics. Research covered many topics from specific nutrients consumption to the imbedding of comprehensive models in integrated management tools. The models contain common components and recurring parts such as the growth of plant and fish as well as some nutrients dynamics. However, if exhaustively compared, they differ significantly in included processes and are often system-specific or architecture-specific. Two modeling works stand out by their scale, degree of completeness and number of applications. Goddek et al. (2016) proposed an agent-based mechanical and dynamic model for aquaponics that has later been completed and adapted to lead the way for additional research and the creation of new models. A lot of specific modeling works have also been committed in the development of models related to the INAPRO aquaponic system. The generated models started as simple descriptive models and ended up being implemented in complex dedicated tools such as manufacturing execution systems.

51However, aquaponic models are mostly application-specific and to this extend, they do not provide any kind of generic traits nor offer any user access. Few studies mention a possible access to the source code on request and only two provide a direct access to the developed tool. Most models are, to our knowledge, inaccessible to the public. Adjusting the mathematical models and tools to other conditions require heavy coding work and significant time involvement. Consequently, no research attempted or succeeded in bringing the aquaponic community around a common modeling project to centralize the knowledge and develop the best possible tool for users and professional growers.

52The aquaponic modeling knowledge has advanced significantly but is evolving in several directions instead of aiming for knowledge sharing and co-development. It is clear that a shared and accessible modeling tool is missing and could greatly help researchers and growers. Future works should focus on gathering the available modeling knowledge generated in previous studies to build a foundation for a comprehensive, accessible, shared and modular modeling tool. This tool would accelerate the development and the adoption of aquaponics. It would also assist players from different fields in the design and management of aquaponic projects, while gathering valuable information and data in a common and evolving project.

Acknowledgements

53We thank the FEDER (“European Regional Development Fund”) for financing the study.

Bibliographie

Ahmed A. et al., 2019. Digital twin technology for aquaponics: towards optimizing food production with dynamic data driven application systems, communications in computer and information science. Springer Singapore, 3-14.

Amin M.T. & Kissock J.K., 2016. Dynamic modeling and verification of an energy-efficient greenhouse with aquaponics. In: Proceedings of the ASME 2016 10th International Conference on Energy collocated with the ASME 2016 Power Conference and the ASME 2016 14th International Conference on Fuel Cell Science, Engineering and Technology, Charlotte, North Carolina, USA, June 26-30, 2016. New York, USA: American Society of Mechanical Engineers, Vol 1., 1-9, doi.org/10.1115/ES2016-59180

Atkinson C. & Kühne T., 2005. Concepts for comparing modeling tool architectures. In: Lecture Notes in Computer Science, 398-413, doi.org/10.1007/11557432_30

Bobak C. & Kunze H., 2016. Modelling an aquaponic ecosystem using ordinary differential equations. In: Mathematical and computational approaches in advancing modern science and engineering, 189-196, doi.org/10.1007/978-3-319-30379-6_18

Cacho O.J., 1997. Systems modelling and bioeconomic modelling in aquaculture. Aquacult. Econ. Manage., 1(1-2), 45-64, doi.org/10.1080/13657309709380202

Cerozi B.S. & Fitzsimmons K., 2017. Phosphorus dynamics modeling and mass balance in an aquaponics system. Agric. Syst., 153, 94-100, doi.org/10.1016/j.agsy.2017.01.020

Danish M.S.S. et al., 2021. A forefront framework for sustainable aquaponics modeling and design. Sustainability, 13(16), 1-13, doi.org/10.3390/su13169313

Dijkgraaf K.H., Goddek S. & Keesman K.J., 2019. Modeling innovative aquaponics farming in Kenya. Aquacult. Int., 27(5), 1395-1422, doi.org/10.1007/s10499-019-00397-z

Estrada-Perez N. et al., 2018. Stochastic modelling of aquaponic production of tilapia (Oreochromis niloticus) with lettuce (Lactuca sativa) and cucumber (Cucumis sativus). Aquacult. Res., 49(12), 3723-3734, doi.org/10.1111/are.13840

Ghandar A. et al., 2021. A decision support system for urban agriculture using digital twin: a case study with aquaponics. IEEE Access, 9, 35691–35708, doi.org/10.1109/ACCESS.2021.3061722

Goddek S. et al., 2016. Navigating towards decoupled aquaponic systems: a system dynamics design approach. Water (Switzerland), 8(7), 1-29, doi.org/10.3390/W8070303

Goddek S. et al., 2019. Decoupled aquaponics systems. In: Goddek S., Joyce A., Kotzen B. & Burnell G.M., eds. Aquaponics food production systems. Cham, Switzerland: Springer, 201-229, doi.org/10.1007/978-3-030-15943-6_8

Goddek S. & Keesman K.J., 2018. The necessity of desalination technology for designing and sizing multi-loop aquaponics systems. Desalination, 428, 76-85, doi.org/10.1016/j.desal.2017.11.024

Goddek S. & Körner O., 2019. A fully integrated simulation model of multi-loop aquaponics: a case study for system sizing in different environments. Agric. Syst., 171, 143-154, doi.org/10.1016/j.agsy.2019.01.010

Hao Y. et al., 2020. States, trends, and future of aquaponics research. Sustainability, 12(18), 1-14, doi.org/10.3390/SU12187783

Jamu D.M. & Piedrahita R.H., 2002. An organic matter and nitrogen dynamics model for the ecological analysis of integrated aquaculture/agriculture systems: I. Model development and calibration. Environ. Modell. Software, 17(6), 571-582, doi.org/10.1016/S1364-8152(02)00016-6

Jones J.W. et al., 2016. Brief history of agricultural systems modeling. Agric. Syst., 155, 240-254, doi.org/10.1016/j.agsy.2016.05.014

Junge R. et al., 2017. Strategic points in aquaponics. Water (Switzerland), 9(3), 1-9, doi.org/10.3390/w9030182

Karimanzira D. et al., 2016. Dynamic modeling of the INAPRO aquaponic system. Aquacult. Eng., 75, 29-45, doi.org/10.1016/j.aquaeng.2016.10.004

Karimanzira D. et al., 2017. Efficient and economical way of operating a recirculation aquaculture system in an aquaponics farm. Aquacult. Econ. Manage., 21(4), 470-486, doi.org/10.1080/13657305.2016.1259368

Karimanzira D. & Rauschenbach T., 2019. Enhancing aquaponics management with IoT-based predictive analytics for efficient information utilization. Inf. Process. Agric., 6(3), 375-385, doi.org/10.1016/j.inpa.2018.12.003

Keesman K.J. et al., 2019. Aquaponics systems modelling. In: Aquaponics food production systems. Cham, Switzerland: Springer International Publishing, 267-299.

Körner O., Gutzmann E. & Kledal P.R., 2017. A dynamic model simulating the symbiotic effects in aquaponic systems. Acta Hortic., 1170, 309-316, doi.org/10.17660/ActaHortic.2017.1170.37

Körner O. et al., 2021. Environmental impact assessment of local decoupled multi-loop aquaponics in an urban context. J. Cleaner Prod., 313, doi.org/10.1016/j.jclepro.2021.127735

Lastiri D.R. et al., 2016. Model of an aquaponic system for minimised water, energy and nitrogen requirements. Water Sci. Technol., 74(1), 30-37, doi.org/10.2166/wst.2016.127

Lastiri D.R. et al., 2018. Model-based management strategy for resource efficient design and operation of an aquaponic system. Aquacult. Eng., 83, 27-39, doi.org/10.1016/j.aquaeng.2018.07.001

Li H. et al., 2021. Adaptive filtering-based soft sensor method for estimating total nitrogen in aquaponic systems. Comput. Electron. Agric., 186, 106175, doi.org/10.1016/j.compag.2021.106175

Mchunu N., Lagerwall G. & Senzanje A., 2019. Aquaponics model specific to South African conditions. S. Afr. J. Agric. Extension, 47(1), 73-91, doi.org/10.17159/2413-3221/2019/v47n1a491

Naegel L.C.A., 1977. Combined production of fish and plants in recirculating water. Aquaculture, 10(1), 17-24, doi.org/10.1016/0044-8486(77)90029-1

Nelson P.V., Sanders D.C., Hodges L. & McMurtry M.R., 1990. Sand culture of vegetables using recirculated aquacultural effluents. Appl. Agric. Res., 5(4), 280-284.

Pamintuan K.R.S. & Doma B.T., 2019. Simulation and assessment of the nitrogen cycle in a constant-head, one pump (CHOP) aquaponics system. IOP Conf. Ser. Earth Environ. Sci., 344, 012001, doi.org/10.1088/1755-1315/344/1/012001

Rakocy J.E., 1994. Aquaponics: the integration of fish and vegetable culture in recirculating systems. In: Proceedings of the Caribbean Food Crops Society, 30th Annual Meeting, July 31-August 5, 1994, St. Thomas, U.S. Virgin Islands, doi.org/10.22004/ag.econ.258746

Ren Q. et al., 2018. A method for predicting dissolved oxygen in aquaculture water in an aquaponics system. Comput. Electron. Agric., 151, 384-391, doi.org/10.1016/j.compag.2018.06.013

Reyes-Yanes A., Martinez P. & Ahmad R., 2020. Real-time growth rate and fresh weight estimation for little gem romaine lettuce in aquaponic grow beds. Comput. Electron. Agric., 179, 105827, doi.org/10.1016/j.compag.2020.105827

Schwartz P.A., Anderson T.S. & Timmons M.B., 2019. Predictive equations for butterhead lettuce (Lactuca sativa, cv. flandria) root surface area grown in aquaponic conditions. Horticulturae, 5(2), doi.org/10.3390/horticulturae5020039

Witzel O., Wilm S., Karimanzira D. & Baganz D., 2019. Controlling and regulation of integrated aquaponic production systems – An approach for a management execution system (MES). Inf. Process. Agric., 6(3), 326-334, doi.org/10.1016/j.inpa.2019.03.007.

Yogev U., Barnes A. & Gross A., 2016. Nutrients and energy balance analysis for a conceptual model of a three loops off grid, aquaponics. Water (Switzerland), 8(12), doi.org/10.3390/w8120589