- Home

- volume 13 (2009)

- numéro spécial

- Compliance of feed limits, does not mean compliance of food limits

View(s): 0 (0 ULiège)

Download(s): 0 (0 ULiège)

Compliance of feed limits, does not mean compliance of food limits

Abstract

The carry-over of contaminants from feed to animal food products is an important aspect of the animal production chain. For a proper containment, limits for feed as well food products are fixed for a series of chemicals, e.g. dioxins and dioxin-like PCBs, lead, cadmium, some chlorinated pesticides, and aflatoxin B1 (and its metabolite M1 in milk). The relationship between feed and food limits is an important issue. An ideal goal is to assure that compliance to a feed limits automatically results in compliance to food limits. In order to collect information about this relationship, several simulation models and a large database on transfer factors have been developed. An optimal choice between either a model or an application of data from the Transfer Database is based on both the knowledge level, and on the circumstances of the specific situation. To reach and validate such an optimal choice an Expert System Carry-Over is currently in development, containing four different modules: 1) the different calculation models and the Transfer Database, 2) a decision tree for choosing the optimal strategy, 3) data tables indicating knowledge levels of compound/animal/product parameters, and 4) supporting databases containing information on consumption and composition of daily diets, animal parameters, and amounts of (daily) production. Calculations indicate that for dioxins compliance to feed levels does not necessarily mean that food limits are complied as well. Besides an estimation of the compliance to limits, the expert system is a tool for feed related risk assessments, and for planning of future research.

Table of content

1. Introduction

1The major reason to set limits to contamination levels of chemicals in animal feeds and feed ingredients is to ascertain that safe levels of those chemicals will be achieved in animal products intended for food. Limits in food are set for some contaminants to avoid high exposure levels for humans. There is a limited range of chemicals for which limits in feed as well as in food are provided: dioxins and dioxin-like PCBs, Aflatoxin B1/M1, cadmium, lead, and 13 “old” pesticides (Directive 2002/32/EC). In most cases the limits in feed and those in food are not empirically related to each other: usually feed limits are related to contamination levels commonly found in practice, applying the principle of as-low-as-reasonably-achievable (ALARA) if desired, whereas food limits are usually based on tolerable daily or weekly intake levels for human consumption.

2This situation results in different backgrounds for feed and food limits, and is due to the lack of sufficient data for carry-over from the feed, through the intestine and the metabolism of the animal to the target organ or product. More recently, tools for calculating this carry-over estimating the final level in the target organ have become available, in combination with relevant data from animal studies.

3Calculation models for simulating the carry-over from feed to food have to be designed and adjusted individually to a specific combination of contaminant-animal-target product. This specific set of data and parameters includes the behavior of the contaminant in the target animal and organs, contamination levels in the diet components, composition of the diet and daily consumption. The level of detail depends on the type of simulation model applied.

4It is vital to obtain relevant compound and animal related data and a possibility to define the correct mathematical model for the actual calculations. Therefore, a group of Dutch research institutes together with the Dutch Food and Consumer Product Safety Authority (VWA) is developing an expert system for performing the complex process of collecting the necessary data, deciding on the simulation model and performing the calculations. This paper presents a preliminary report on the development of an Expert System Carry-Over.

2. Modeling carry-over

5The simulation of the deposition or excretion of contaminants from feed to animal products for human consumption such as meat, milk and eggs, and of the elimination of the compound via metabolism or excretion can be achieved in several ways.

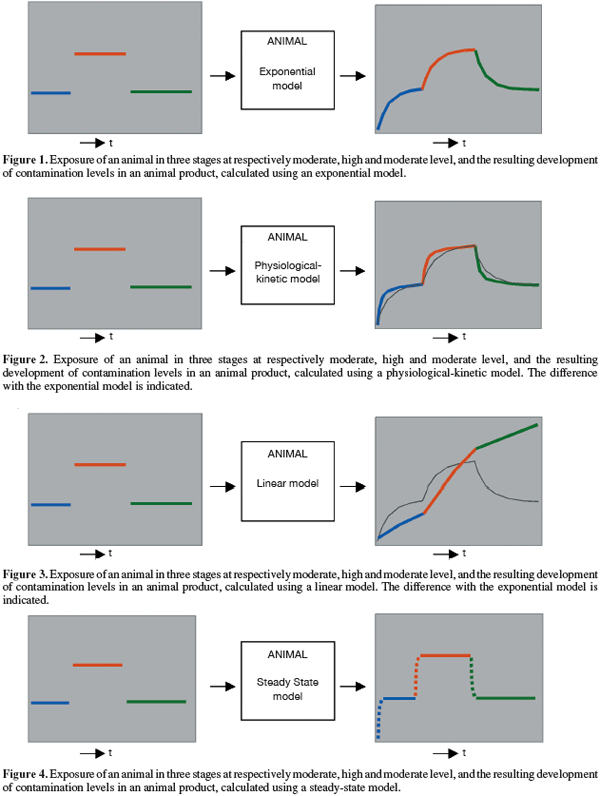

6Let us assume a situation in which an animal is exposed for a certain period of time to a chemical compound at a background level, followed by a second period of excessive exposure, and a third and last period of time with (again) exposure at background level. A first choice might be the application of an exponential model, which can explain the accumulation or the elimination by a gradual achievement of a Steady State level1. The slope and final level of the curve depend on several parameters. These are in non-mathematical terms the carry-over rate to the target organ or product, and the half-life time of the chemical in the target animal. A schematic representation is given in figure 1 (van Raamsdonk, in preparation). For this model, as applies to the other approaches as well, data on the consumption amount, composition of the daily diet, composition of the animal (e.g. age related), and weight of the target organ or product are needed for a successful application of the model.

7Another more detailed approach is the use of physiological-kinetic models, in which different body compartments are considered simultaneously (e.g. blood serum, body vs milk fat, different organs, etc.). Such models allow to predict more precisely the accumulation or elimination in the course of time, since different half-life times might apply to the different compartments. Because of that, a larger set of parameters is needed. The possibility of different half-life times is reflected in different slopes for parts of the curves. In figure 2 the estimation in the first part of each of the three periods of exposure is estimated more accurately compared to exponential modeling (e.g. van Eijkeren et al., 2006).

8In certain cases the elimination of the chemical compound might be (almost) zero. The parameter half-life time is very high or infinite in these cases. Linear models can easily be applied in which the speed of the accumulation (the slope of the line) is directly calculated from the level of the exposure (Figure 3).

9On the other hand, the parameter half-life time can be (extremely) low. For some chemicals the situation applies that in a few hours or days the balance between accumulation and elimination has been reached (Steady State). In situations where only the Steady State period is of interest, the final level can be calculated with ignorance of the half-life time, using the direct relationship (carry-over rate) between exposure and Steady State level (Figure 4).

10The availability of parameters, or in more general terms the level of knowledge, for a combination of chemical compound/target animal/target organ or product, directs partly the choice for a particular model. In a large range of cases reliable parameters are not available at all. In such cases data and results from literature can be selected, which describe as good as possible the situation at hand. A meta-analysis of published experiments was carried out. From each dataset a transfer factor was extracted, that describes the behavior of the contaminant as precise as possible for the specific circumstances. In a more general approach physical parameters for the chemical compound or for the entire group (e.g. heavy metals) can be extracted from literature. These physical parameters can be used to predict the behavior of the compound in the animal body. A large Transfer Database is available with data from literature and scientifically approved factors (Leeman et al., 2007).

3. Model choice

11The choice for the optimal model or dataset depends on two major aspects: the level of knowledge as mentioned, and the circumstances of the specific situation that leads to performing the calculations.

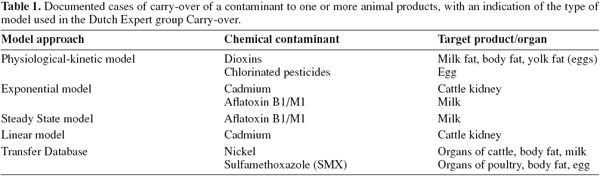

12Reliable application of simulation models for carry-over is not exclusively based on the presence of a (set of) mathematical equation and parameters, but also on the calibration and validation of the model used. Up to now a set of models is tested and documented for several situations in The Netherlands, as are listed in table 1.

13Models and data can be used for the verification of compliance to feed and food limits. The same tools can be used in case of incidences with high exposure. It is, however, not obvious in all cases that the parameters carry-over rate and half-life time can be used for all possible levels of exposure. For some chemicals (e.g. lead) other parameters apply in situations of incidental high exposure compared to moderate (level of feed limits) or low (background) levels. The type of assessment and the type of questions (are predictions requested for an expected withdrawal period to reach levels below the limit, or for an expected level) direct the choice for the model to be applied as well.

4. Necessary data

14Several types of data are necessary to apply successfully the presented models. These are:

15– composition of the animal daily diet: share of compound feed, fodder and other sources, composition of the compound feed,

16– amount of the daily consumption,

17– animal parameters (animal total weight, share of the different organs or tissues, daily production, growth of the animal),

18– contamination levels of the target chemical compound in feeds and feed ingredients. For compliance to feed and food limits the limit values can be applied. In the case of an incidence the incidental high contamination levels are to be used,

19– parameters of the chemical compound. In a lot of cases a contaminant is metabolized in the animal, resulting in metabolites with a lower or higher toxicity. A situation where the contaminants or its metabolites are excreted, an exponential equation can be applied, where carry-over rate and half-life time describe sufficiently such a situation. A kinetic mass balance between intake, plasma, organs and excretion can be described by using a physiological-kinetic model, requiring exchange parameters between the different compartments. The application of more than one model or parallel running models might be desired when metabolites have their own toxic effect and toxicity level. In all these cases (large ranges of) parameters should be readily available from studies and literature. As an alternative estimations can be made, solely based on physical parameters extracted from the database. In all cases information on the bioavailability (absorption in the intestine) need to be available

20– data on the normal occurring background levels in feed and food products (Dutch database KAP). These data can be used for calibration of the models. Provided all the data and parameters from databases or from literature and given the normal (background) exposure of the contaminant in the daily diet of the target animal, the model should estimate the normally occurring contamination level of the contaminant in the food product under study.

21The results of the calculations depend for a large extent on the reliability and estimation of all parameters and data. “Average” animals and daily data can be assumed, but local or regional differences can deviate largely. Expert judgment for both the source and the validation of parameters and data is essential in all cases.

5. Example: dioxin carry-over to milk

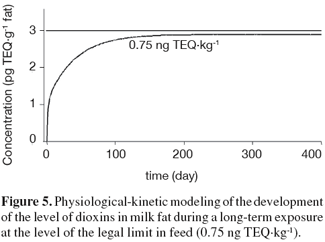

22Dioxins cause an important burden on the production chain of animal products for human consumption. Several incidences have occurred in the past (e.g. Hoogenboom et al., 2005; 2007). It is important to know the relationship between the feed and food limits for dioxins in terms of totalTEQ; comparison is possible since limits for both feeds and products of animal origin have been set. Calculations based on levels of totalTEQ are allowed for a series of different dioxin congener spectra (van Raamsdonk et al., in preparation). A typical set of parameters for the carry-over from feed to milk fat consists of:

23– consumption of dry matter: 15 kg per day (source: ASG),

24– feed limit: 0.75 ng TEQ.kg-1 (source: Directive 2006/13/EC),

25– the daily exposure at maximum allowed level: 11.25 ng TEQ per day,

26– animal production: 1 kg milk fat per day (25 liter milk with 4% milk fat; source: ASG),

27– food limit: 3 pg TEQ.g-1 milk fat (source: Regulation 199/2006/EC).

28The prototype of the decision tree directs to the application of a physiological-kinetic model approach. The data table with information on the availability of a sufficient knowledge level indicates that a set of parameters for the compound/product combination is readily available to apply this approach.

29Calculations indicate that with the mentioned parameters and the parameters for the physiological-kinetic model a Steady State level will be reached just below the legal limit of 3 pg TEQ.g-1 milk fat (personal communication van Eijkeren, RIVM, figure 5). For comparison, exposure of laying hens to the feed limit (0.75 ng TEQ.kg-1) will result in an excess of the food limit in eggs (3 pg TEQ.g-1 yolk fat). The expected level will be approx. 13 pg TEQ.g-1 yolk fat, depending on the feed regime. In order to reasonably avoid excess of the food limit, feed limits are being predicted to be around 0.17 ng TEQ.kg-1 (van Eijkeren et al., 2006).

30Other examples are currently available in the Dutch Expert group Carry-Over: cadmium to kidney in cattle (Franz et al., 2008), nickel to cattle (Leeman et al., 2007), aflatoxin B1 to M1 in milk (unpublished results) and sulfamethoxazole (SMX) to chicken (Leeman et al., 2007).

6. The Expert System Carry-Over

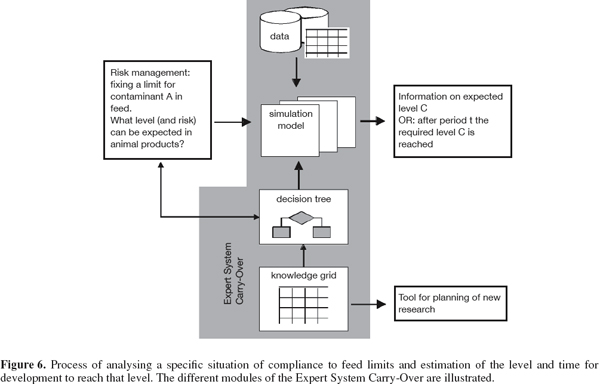

31This expert system is planned to consist of four different modules (see also figure 6).

32Calculation models. Documented time based physiological-kinetic (van Eijkeren et al., 2006), exponential and linear models (Franz et al., 2008), as well as Steady State models and a comprehensive database on carry-over (Leeman et al., 2007) are available (see also table 1).

33Decision tree. Based on circumstances of the assessment, the level of expertise and the combination chemical compound-animal-target product, a decision tree guides the user to the optimal choice for a simulation model.

34Knowledge grid. A table ordered along chemical compounds and target animal/organ consists of indications for the level of expertise currently present in the group of experts, and of subtables for specific groups of chemicals, e.g. heavy metals, mycotoxins, chlorinated pesticides. Every cell is, when applicable, supported by a page with a summary of the literature available and of the primary indicators. Parameters for a range of chemical compounds are published and discussed by Kan et al. (2007).

35Databases. Data on consumption amount, composition of the daily diet of major farm animals, background levels of chemical compounds in feeds, overview of legal limits, and data on composition of animals and production of animal products are collected in order to provide data for calculations.

36The expert system is currently in development and, as already mentioned, prototypes of parts are available.

37A further development is the connection of animal carry-over models with soil-plant transfer models, in order to estimate contamination levels in roughage based on the available levels of the contaminant in soil. Estimations of levels in vegetables and animal products can be used as input for human exposure models. A chain of models including interactions between soil, plant, animal product and human exposure has been used to describe the cadmium contamination levels in the food production chain (Franz et al., 2008).

7. Conclusion and recommendations

38The dioxin example shows that compliance to a feed limit does not necessarily mean that food limits for all animal products are not exceeded. It appears possible to estimate the carry-over of a particular chemical compound to an animal product by using a calculation model or by derivation of transfer factors from the Transfer Database. The optimal choice can be directed by using a decision tree based on the circumstances of a specific situation and the available knowledge. Supporting information on consumption and production is present.

39An Expert System Carry-Over can provide the necessary means for achieving several goals:

40– setting feed and food limits, and estimating the compliance between these limits,

41– calculation of the ALARA contamination level throughout the production chain (ingredient-feed-product),

42– deciding on the optimal choice for a calculation model for a particular incidence (and possible risk) in the chain,

43– providing an overview of expertise levels for individual chemical contaminants and groups of contaminants.

44A useful side-effect of having tables with summaries of the available expertise is the support for future research planning.

45It is strongly recommended to continue the development of this expert system at a European level. Integration of an Expert System Carry-Over with the other steps of the food production chain (e.g. soil-plant interactions and human exposure models) will greatly enhance the possibilities for risk analysis and management of chemical components.

Bibliographie

European Commission, 2002. Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed as regards dioxins and dioxin-like PCBs. Off. J. Eur. Community, L 140, 30.05.2002, 10.

European Commission, 2006. Commission Directive 2006/13/EC of 3 February 2006 amending Annexes I and II to Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed as regards dioxins and dioxin-like PCBs. Off. J. Eur. Community, L 32, 04.02.2006, 44.

European Commission, 2006. Commission Regulation (EC) n°199/2006 of 3 February 2006 amending Regulation (EC) n°466/2001 setting maximum levels for certain contaminants in foodstuffs as regards dioxins and dioxin-like PCBs. Off. J. Eur. Community, L 32, 04.02.2006, 34.

Franz E., Römkens P.F.A.M., van Raamsdonk L.W.D. & Fels-Klerx I., 2008. A chain modeling approach to estimate the impact of soil cadmium pollution on human dietary exposure. J. Food Prot., 71(12), 2504-2513.

Hoogenboom L.A.P. et al., 2005. Kaolinic clay derived dioxins in potato by-products. Organohalogen Compd, 67, 1470-1473.

Hoogenboom L.A.P. et al., 2007. A novel source for dioxins present in recycled fat from gelatin production. Chemosphere, 68(5), 814-823.

Kan C.A. & Meijer G.A.L., 2007. The risk of contamination of food with toxic substances present in animal feed. Anim. Feed Sci. Technol., 133, 84-108.

KAP (database). http://www2.rikilt.dlo.nl/kap/index.html.

Leeman W.R., Van Den Berg K.J. & Houben G.F., 2007. Transfer of chemicals from feed to animal products: the use of transfer factors in risk assessment. Food Addit. Contaminants, 24(1), 1-13.

van Eijkeren J.C.H. et al., 2006. A toxicokinetic model for the carry-over of dioxins and PCBs from feed and soil to eggs. Food Addit. Contaminants, 23, 509-517.

Notes

To cite this article

About: Leo W.D. van Raamsdonk

RIKILT. Institute of Food Safety. P.O. Box 230. NL-6700 AE Wageningen (The Netherlands). E-mail: Leo.vanraamsdonk@wur.nl

About: Jan C.H. van Eijkeren

RIVM National Institute of Public Health and the Environment. Postbus 1. NL-3720 BA Bilthoven (The Netherlands).

About: Gerwin A.L. Meijer

Animal Sciences Group of Wageningen UR (ASG). Division Nutrition and Food. P.O. Box 65. NL-8200 AB Lelystad (The Netherlands).

About: Monique Rennen

Toegepast Natuurkundig Onderzoek (TNO). Division Quality of Life. Utrechtseweg 48. NL-3704 HE Zeist (The Netherlands).

About: Marco J. Zeilmaker

RIVM National Institute of Public Health and the Environment. Postbus 1. NL-3720 BA Bilthoven (The Netherlands).

About: L. (Ron) A.P. Hoogenboom

RIKILT. Institute of Food Safety. P.O. Box 230. NL-6700 AE Wageningen (The Netherlands).

About: Marcel Mengelers

Food and Consumer Product Safety Authority (VWA). P.O. Box 19506. NL- 2500 CM The Hague (The Netherlands).