Kivuguto traditional fermented milk and the dairy industry in Rwanda. A review

Univ. Liege - Gembloux Agro Bio-Tech. Passage des Déportés, 2. B-5030 Gembloux (Belgium). E-mail: eugene.karenzi@doct.ulg.ac.be – National University of Rwanda. P.O.Box 117. Butare (Rwanda).

National University of Rwanda. P.O.Box 117. Butare (Rwanda).

Ministry of Agriculture Rwanda. P.O.Box 5016. Kigali (Rwanda).

National University of Rwanda. P.O.Box 117. Butare (Rwanda).

Univ. Liege - Gembloux Agro Bio-Tech. Passage des Déportés, 2. B-5030 Gembloux (Belgium).

Received on March 27, 2012; accepted on January 7, 2013

Résumé

Lait fermenté traditionnel kivuguto et l’industrie laitière au Rwanda (synthèse bibliographique). La fermentation traditionnelle du lait, de loin la plus pratiquée au Rwanda, est effectuée par des micro-organismes indigènes. Cela conduit à la production d'une variété de saveurs dans les produits laitiers fermentés. Le kivuguto, un produit laitier obtenu par cette fermentation, est caractérisé par un manque de maitrise de qualité aussi bien dans l’espace que dans le temps. Elle est produite par l'acidification spontanée du lait cru par une microflore rencontrée dans les ustensiles utilisés pour la conservation du lait et dans l’environnement proche du bétail. Face à une telle situation, les laiteries modernes produisent du lait fermenté et autres produits laitiers en utilisant des souches exotiques. L’objectif principal de ce travail est de documenter la production traditionnelle du kivuguto et ses sous-produits, et d’extrapoler à la situation actuelle de l’industrie laitière au Rwanda.

Abstract

Traditional methods of fermenting milk involve the use of indigenous microorganisms, leading to the production of a variety of tastes in fermented milk products. Kivuguto is a fermented milk product, which is popular in Rwanda. Kivuguto is produced by traditional spontaneous acidification of raw milk by a microflora present both on utensils and containers used for milk preservation and in the near environment of cattle. Thus, this method does not allow the shelf stability of the product. Faced to such a situation, modern dairies now produce fermented milk and other dairy products using exotic strains. The main objectives of this paper are firstly, to provide documentation on the traditional production of kivuguto, as well as its by-products, and secondly, to describe the current situation of the dairy industry in Rwanda.

1. Introduction

1Rwanda is located between latitudes 1°04’ and 2°51’ South and longitudes 28°45’ and 31°15’ East. It is a landlocked country situated between Burundi in the South, Tanzania in the East, the Democratic Republic of Congo in the West and North-West and Uganda in the North. Its altitude above sea level varies from 1,000 m to 4,507 m, with the highest point situated at the Karisimbi volcano, one of six in a chain of volcanoes extending from the far east of Congo to the North-West of Rwanda. Rwanda has a temperate tropical highland climate, with temperature variations across the country of between 14 °C and 25 °C. There are two rainy seasons in the year, from February to June and from September to December, and two dry seasons from June to September and from December to February. Rainfall varies geographically, with twice as much average annual precipitation in the West as in the East. These environmental conditions give Rwanda a mild and cool climate, which guarantees good pasture, providing sustainable welfare conditions for animals. Animal husbandry has been an integral part of the Rwandese culture for many centuries. Cattle, in particular, have served as a symbol of political power and have been the traditional mainstay of the Rwandese economy (Adekunle, 2007). Rwanda is faithful to its agro-pastoral tradition and, as such, over the centuries, the cow has taken on an importance in all areas of the country’s culture. In all the social activities associated with cows (language, ceremonies, speeches, customs and taboos in their honor), the symbolic value of the animals transcends their economic value. Nevertheless, cows have been exploited for centuries by the Rwandese people for their meat, skin and milk. It is believed that milk has been consumed since the domestication of cattle. Milk represents an important food, and its nutritional value as well as its many health benefits have been well known to Rwandese society since ancient times. Milk consumption used to be the privilege of a few rich families and, as such, cows have played a somewhat divisive role in Rwandese society. Today, attempts are being made to build a new society where all people share the same values. As part of this approach, opportunities are being created and different policies are being implemented in order to develop the livestock sub-sector and the dairy industry in particular. Agriculture now contributes 40% to Rwanda’s national GDP (Gross Domestic Product), of which 8.8% comes from livestock (animal resources). According to Rutamu (2008), annual milk production in Rwanda in 2005 was estimated at 178,598 tons of milk, and this quantity is not sufficient to satisfy the needs and requirements of the population. The average milk consumption in Rwanda is 0.035 l per person per day (13 l of milk per person per year) and 75% of that milk is consumed in rural areas. Given this situation, the country is forced to import milk from Uganda and Kenya. The Ministry of Agriculture (MINAGRI) has set up strategies and programs to improve the dairy farmer’s capacity and organizational skills, with an emphasis on the dairy chain and on the strengthening of the institutional framework at central and local levels (MINAGRI, 2009). In the present paper, an overview of traditional technology for producing kivuguto and its by-products is presented. New trends for the development of the dairy industry in Rwanda as well as information on milk consumption and the milk market are also discussed.

2. Kivuguto and its by-products

2.1. Kivuguto processing technology

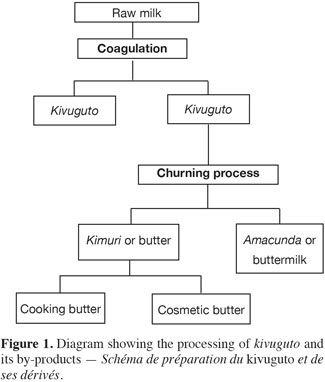

2In the traditional method of producing kivuguto, once the cow has been milked, the milk is placed in a jar called an inkongoro. After this, the milk is poured into a big, clean, wooden jar called an icyansi and is left at room temperature in a warm and clean place called an uruhimbi. In order to keep the product safe, the jar is usually covered either with a straw-woven lid known as an umutemeri or with a lid made from a calabash. A fermentation period of at least 2 to 3 days is required in order to obtain good kivuguto. Figure 1 shows a flow chart for the traditional processing of kivuguto and its by-products. The typical flora that creates the traditional sour milk, kivuguto, was not, to date, specifically selected and applied in producing the drink in dairy. This flora is very complex and varies from one location to another, as it is the case for all traditional curds. In addition, the lactic flora lives alongside a pathogenic flora, which also varies depending on the level of the personal hygiene of those preparing the kivuguto. Nevertheless, despite the disadvantages of the process, traditional fermentation remains the most convenient method in Rwanda. The microorganisms used are indigenous strains, which are left to develop naturally during the production process. However, in order to standardize this process, the need has arisen for the selection and application of specific strains. These microorganisms are responsible for the acidification, texture, flavor and other organoleptic characteristics, which give the kivuguto curd its highly appreciated taste. This microflora is found in containers commonly used for storing milk. Its habitat is also easily located in the near environment of cattle (pasture, paddock, cattle dander, air, etc.). The preparation of the kivuguto curd varies between regions. In most cases, raw milk is stored directly in a vessel until it ferments spontaneously via microorganisms contained in the milk. These microorganisms come either from inside container or from the air in the surrounding environment. Note that in all methods of kivuguto production, the vessel is not hermetically sealed. Also, from time to time, the kivuguto of a previous batch is used in small quantity as a starter added into new fresh milk. In other cases, raw milk is first heated to boiling point and then cooled to room temperature. It is then stored for 24-36 h before coagulation.

3In areas of eastern Rwanda, the containers in which the milk is stored undergo special preparation: washing with the hot smoke derived from burning two species of plant, one of which is an herb of the Poaceae (grass) family, and the other a shrub called Combretum molle. The grass used is first stripped of its roots and all its leaves, leaving a single short stem, which is then dried in the sun. These dried stems (rods) are then collected into small bundles and are stored for more than six months in the house. During this time, smoke from the kitchen covers the bundles of rods with a reddish layer. At the end of this period, these rods are burned in a small pot fitted with one large and one small opening. First, the rods are inserted into the large opening of this small pot and are burnt, second the mouth of a vessel – a small wooden vessel (inkongoro), or a small gourd – is placed over the smaller opening of the pot in order to capture all the smoke that emerges. After a while, the vessel is removed and the inside is wiped with a kind of cloth made out of tree bark. The vessel is then placed back over the emerging smoke, then removed and wiped inside again, and so on. The exercise is repeated several times in order to make the inside of the vessel very smooth. At the end of the procedure, the vessel is kept closed. When milk is placed in a container prepared in this way, the fermentation process takes about 36 h, and a very good curd is produced, with a solid texture. For larger containers, the washing process is carried out using smoke obtained by burning a single large stem of the shrub, which has not been completely dried. The stem is burned and the vessel is held upside down directly over the smoking stem. The vessel is then wiped several times as before. In both procedures, the fermented milk stored in these containers has a smell and taste of smoke, which is highly appreciated both by Rwandese people and by others in the region. What is clear is that this smoking process ensures that these containers are clean, so that there are usually very few pathogens affecting the texture of the curd.

2.2. The traditional churning process

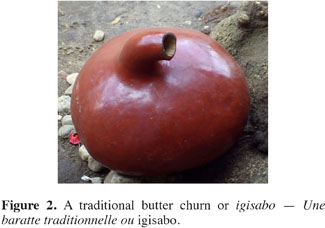

4Milk stored in a small gourd will ferment to give kivuguto milk, which is then used in this liquid form. On the other hand, when milk is left to ferment in a large gourd (igisabo), or in a calabash (Figure 2), additional processing is applied to the resulting kivuguto milk. Here the kivuguto is churned to produce kimuri (butter) or amacunda (buttermilk). In order to produce these products, the kivuguto is first of all stirred while it bubbles in a butter churn usually in the form of the calabash in which the milk was fermented. This churning process takes at least 2 h. During this time, the fat from the kivuguto coalesces and the separation between liquid and solids becomes more marked. The fat is removed and the liquid left behind in the churn is buttermilk, a product drunk as such. Buttermilk produced in this way has a characteristically sour taste caused by lactic acid bacteria involved in milk lactose hydrolysis during fermentation. The extracted fat is then used in one of two ways. It may be heated with some natural perfuming additives to be used as a cosmetic body cream. On the other hand, the fat may be well preserved for a half-year or a full-year period, allowing the manufacture of a solid tasting yellow fat called butter or amavuta akuze, which is good for food preparation. Sometimes, this butter is seasoned with additional ingredients such as onions, garlic, etc., in order to add flavor to meals.

3. Characterization of kivuguto

3.1. Microflora

5In a previous study (Karenzi et al., 2012), we investigated the characteristics of kivuguto. Using two samples of kivuguto from northern and southern provinces of Rwanda, we selected the microorganisms responsible for the fermentation of the product and formulated a starter culture composed of three strains: CWBI-B1466 Lactococcus lactis registered in the Genbank database under accession number JF313446, CWBI-B1465 Leuconostoc mesenteroides subsp. mesenteroides, accession number JF313445 and CWBI-B1470 Leuconostoc pseudomesenteroides, accession number JF313454. Kivuguto has a lot of similarities with kule naoto, a traditional fermented milk of Kenya. The dominant lactic acid bacteria of kule naoto belong to the genus Lactobacillus, followed by Enterococcus, Lactococcus and Leuconostoc (Mathara et al., 2004). Kivuguto also presents some similarities with urubu, a traditional fermented milk of Burundi (Nzigamasabo et al., 2009). To date, the microorganisms of urubu have not been selected. Isono et al. (1994) found that the major microorganisms of the Masai fermented milk in Northern Tanzania consist of Lactococcus lactis ssp. lactis and Lactobacillus confus. Since 1992, a similar study was carried out on traditional fermented milk of Zimbabwe, amasi (Feresu, 1992). Assays for formulating a starter culture for the production of amasi were conducted with isolates of Lactococcus lactis subsp. lactis biovar lactis, Lactobacillus plantarum and Leuconostoc mesenteroides subsp. mesenteroides (Mutukumira, 1996). However, a sensory panel was subsequently found to prefer amasi produced by a single strain of Lactococcus (Gadaga et al., 1999). Lactococcus lactis is the strain responsible for the fermentation of an israeli milk called zivda. The strain is found in many dairy products and is used mainly for its acidifying property. In Sudan, a combination of lactic acid bacteria and yeasts is responsible for the fermentation of the traditional fermented milk, rob. The predominant lactic acid bacteria in rob fermentation have been found to be Lactobacillus fermentum, Lactobacillus acidophilus, Lactococcus lactis and Streptococcus salivarius (Abdelgadir et al., 2001). The predominant yeasts have been identified as Saccharomyces cerevisiae and Candida kefyr (Abdelgadir et al., 2001). This association of lactic acid bacteria and yeasts is also found in the fermented milk of Ethiopia, and in the kefir and koumis milks of Eastern European countries. The taste of these fermented milks displays an alcoholic flavor and is less sour, properties that are not well appreciated in Central and East Africa. Kivuguto also resembles to yogurt, the well-known example of a fermented milk product. However, the taste is different and the strains of fermenting bacteria used in yogurt are also different: Lactobacillus bulgaricus and Streptococcus thermophilus. Taste is the sole reason why people of the Great Lakes Region (Africa) continue to prefer the traditional kivuguto, although yogurt is also sold at the local market. Of all the fermented milks discovered to date, the one most similar to kivuguto is the filmjölk of Sweden, in terms of both consistency and flavor. When people from Central Africa stay in Europe, they usually consume this milk more than they do yogurt. Filmjölk is a mesophilic fermented milk, which, like kivuguto, is also composed of two strains of Lactococcus lactis and Leuconostoc mesenteroides. Filmjölk flavour is also very similar to lben of Morocco (Tantaoui-Elaraki et al., 1987), a buttermilk fermented by Lactococcus lactis subsp. lactis biovar diacetylactis, Leuconostoc lactis, Leuconostoc mesenteroides subsp. cremoris and Leuconostoc mesenteroides subsp. dextranicum.

3.2. Acidification and physico-chemical properties of kivuguto

6The acidification process of kivuguto is created by two strains: CWBI-B1466 Lactococcus lactis and CWBI-B1470 Leuconostoc pseudomesenteroides. The third strain responsible for the acidification of kivuguto – Leuconostoc mesenteroides subsp. mesenteroides – does not grow on its own in milk. In order to reach the isoelectric point at pH 4.6, CWBI-B1466 Lactococcus lactis takes 8 h whilst CWBI-B1470 Leuconostoc pseudomesenteroides takes 14 h. At that point, the titratable acidity is more than 80 °D. After 4 h of fermentation, a coagulum begins to form. For a period of up to 8 h, the kivuguto appears as a semi-solid pleasantly sour product. However, before it is suitable for drinking, it needs to be blended. Kivuguto keeps well for up to 36 days at 4 °C, maintaining its good flavor; its visco-elastic properties also increase with the duration of storage.

4. The dairy industry in Rwanda

4.1. Dairy policy

7The livestock (animal resources) sub-sector falls under the responsibility of the Ministry of Agriculture and Animal Resources (MINAGRI). Since 2006, the activities of this sub-sector have been implemented by the Rwanda Animal Resources Development Authority (RARDA), as part of the global program of the National Animal Resources Policy. In Rwanda, there is no dairy sub-sector as such, but cattle farming plays a very important role in the socio-economic activities of the country. Farming of goats, sheep, pigs, chickens, fish and rabbits is less well developed. To date, the livestock (animal resources) sub-sector has been represented mostly by cattle development projects. In 2003, the Dairy Cattle Development Support Project (PADEBL) was created as a separate project with the specific objective of satisfying domestic demand for milk and beef, as well as of increasing the income of farmers. This project contributed to the implementation of the “One cow per poor family” (Girinka) program, launched in 2006 to provide cows for poor families. PADEBL is also responsible for milk quality management: it created and now owns many milk collection centers (MCCs), each with its own cooling system. PADEBL is financed by the African Development Bank (ADB). From 2010, MINAGRI restructured its activities. MINAGRI comprises a Permanent Secretariat to coordinate the ministry’s policies and programs through two units at central level: the Strategic Planning & Program Coordination Secretariat (PPS) and the Internal Resource Management & Finance Unit; and through two boards at decentralized level: the Rwanda Agriculture Board (RAB), and the National Agriculture Export Development Board (NAEB). RAB comprises four departments: Agriculture Extension (formerly RADA – the Rwanda Agriculture Development Authority), Livestock (Animal Resources) Extension (formerly RARDA), Research (formerly ISAR) and Infrastructure & Mechanization. Within the new structure, the sub-sector coordinates the issuing of certificates authorizing imports of domestic animals, semen, fertilized eggs, seeds, plants and cuttings and other animal husbandry products. It also works in livestock research, training and information. In addition to inheriting the “One cow per poor family” (Girinka) program, the sub-sector is also responsible for the “One cup of milk per child” program, and the “Poultry and Hatchery, Insemination and Small Stock” program (RAB, 2012). The Girinka program aims at enabling every poor household to own and manage a productive dairy cow, enabling the family to improve their livelihood through increased milk and meat production and to improve the soil fertility of their land for their crops using the available manure (RAB, 2012). The “One cup of milk per child” program is a school milk program funded by the European Union (EU) to provide milk to children in nursery and primary schools in order to address the country's problem of severe child malnutrition (RAB, 2012).

4.2. Milk production and processing

8Milk production in Rwanda was estimated to have reached 372,619 tons by 2009 (DMS, 2009), following tremendous efforts made by the government and other stakeholders. In order to promote milk production in the country, emphasis was placed on bovine genetic improvement (strengthening the use of artificial insemination, and the importing of exotic cows). Most of the milk in Rwanda (48%) is produced in traditional or extensive grazing system in the Eastern Province (Rutamu, 2008). The 2006 Agriculture Survey indicated that there were 1.2 million cattle in Rwanda, of which 13.6% were milking cows. The survey also indicated that there were a total of 157,479 milking cattle; improved breeds constituted 23% of that group, pure breeds 6% and crosses 17% (PADEBL, 2009). In 2010, the NISR (National Institute of Statistics of Rwanda) revealed the number of dairy cattle in the country to be 207,507, corresponding to an increase of 25%. The overall total number of cattle was confirmed to be 1,548,521, with 15.5% of these being represented by exotic breeds (Modderman, 2010). The Rwandese dairy industry currently consists of five dairy companies: Inyange Industries, Nyanza Dairy, Eastern Savannah, Rubilizi Dairy, Masaka Farms plus several cheese processing units mainly located in the Western Province (20 cheese processing units), with a few others being found in other parts of the country (RBS, 2011). Two of these cheese processing units are located in Nyanza District and two more are found in Gasabo District. According to Rutamu (2008), the milk processing capacity available in Rwanda is estimated at 188,000 l per day, but only 3.3% of this capacity is used. Today, these data may be revised, if we take into consideration milk processed for cheese making and the existence of new dairy processing units. Milk technology is applied in the Rwandese dairy industry in the processing of the following dairy products: pasteurized milk, skimmed milk, cream, flavored milk, fermented milk and yogurt, UHT milk, and cheeses such as Gouda, butter, ice cream.

4.3. Milk consumption and importation

9High population growth in Rwanda has led to an increase in demand for livestock products that is higher than can be satisfied by domestic production. This has forced the country to invest its few financial resources in the massive importation of milk (Rutamu, 2008). From 1999 to 2007, the trend in milk imports decreased from 1,280 t to 450 t (MINAGRI et al., 2007). It is very difficult to make an accurate estimation of milk consumption in Rwanda, because a large volume of milk is sold in the informal market. In 2007, approximately 62,000,000 l were consumed on farms and about 35% of raw milk was lost due to spoiling before reaching the market or being processed (TechnoServe, 2008). In 2008, a chain analysis estimated that 96% of all dairy products are sold in the informal market, e.g. in small informal milk shops. Kigali city has more than 1,500 milk shops (Modderman, 2010). Milk is consumed either fresh or after coagulation. As Rwandese people prefer fermented milk, it is very difficult to estimate the percentage of fresh milk consumed out of the 96% of all dairy products sold at the informal market.

4.4. The dairy value chain in Rwanda

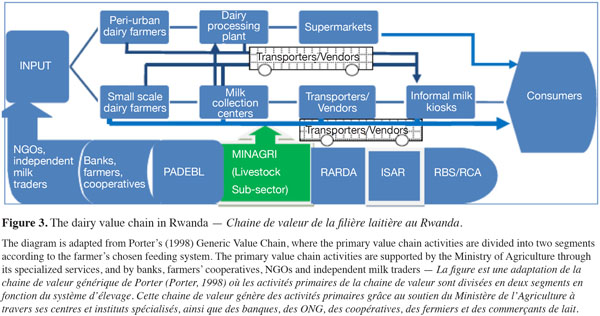

10Michael Porter was the first to use the concept of the “value chain”. Within a firm or organization, both the service provided and the product made add value according to the activities and processes employed by the organization. Value chains traditionally refer to the chain of activities that products pass through as they gain value before reaching the consumer (TechnoServe, 2008). Along the chain, the organization is split into primary activities and support activities (Porter, 1998). The dairy value chain in Rwanda follows two main segments of actors, with the segments being composed of multiple nodes. The two segments are linked to input providers (Figure 3) organized by the Ministry for Agriculture and Animal Resources (MINAGRI) through the Rwanda Livestock sub-sector and other stakeholders (other state organizations, NGOs and independent traders).

11Dairy value chain input providers. Since 2006, under the Ministry of Agriculture, RARDA (Rwanda Animal Resources Development Authority) and ISAR (Institute of Agronomic Sciences of Rwanda) have supported the dairy value chain at different levels. The mission of RARDA was to contribute towards the growth of animal production through the development of appropriate technologies, and by providing advisory, outreach and extension services to stakeholders in the animal resources sector (RARDA, 2010). Since 2003, PADEBL (Dairy Cattle Development Support Project) has contributed to a sustainable increase in milk and meat production, through the introduction of appropriate technological packages into stockbreeding in villages and peri-urban areas (MINAGRI, 2009). ISAR was the body responsible for research and development at MINAGRI. ISAR’s mandate was to carry out research on agronomy, and on animal and environmental sciences (ISAR, 2010). The Rwanda Bureau of Standards (RBS), under the Ministry of Trade and Industry (MINICOM), is the statutory body charged with the enforcement of standards and the certification of all products and services in the country (RBS, 2011). The Rwanda Cooperative Agencies (RCA) is a public institution in charge of the promotion, registration and regulation of cooperatives in the country. The livestock sub-sector receives a lot of support from RCA for the dairy development, since many cooperatives are involved in the dairy chain. Other stakeholders in the livestock sub-sector are ADB (African Development Bank), BNR (Banque Nationale du Rwanda), BPR (Banques Populaires du Rwanda), BRD (Rwanda Development Bank) and other commercial banks; NISR (National Institute of Statistics of Rwanda); independent traders (veterinarians, transporters, etc.); farmers’ cooperatives and many NGOs (non-governmental organizations). Today, the three support institutions of MINAGRI: RARDA, ISAR and PADEBL are part of the Livestock sub-sector within the new structure and they have the same mission as previously in terms of the dairy development program.

12Dairy value chain actors. Informal actors are present throughout the two segments. From the farmer to the consumer, dairy activities are conducted by dairy processors, supermarkets, collection centers, transporters, and traders and retailers. Farmers are categorized according to the feeding system they use: free-grazing, semi-grazing or zero-grazing. Individual cattle farmers generally practice free-grazing and they produce milk for domestic consumption. Sometimes, surplus milk is sold to a retailer, a transporter or a cooling system owner. This cattle husbandry system represents the vestige of the old system; MINAGRI discourages this system and supports instead zero grazing. Zero grazing is practiced mostly by peri-urban farmers. These farms are well equipped around Kigali city, and the owners have invested both in large numbers of cattle and in equipment in order to supply dairy processing units. Semi-grazing systems have sufficient land and, with a low level of investment, they are able to produce milk to supply a retailer, a transporter, a cooling system owner or a processor. The processor then supplies dairy products to supermarkets. Semi-grazing and free-grazing husbandry farmers are categorized as “small scale farmers” along the dairy value chain. Cooling systems mainly belong to PADEBL and to some farmers’ cooperatives. These cooling systems are held in milk collection centers (MCCs). Transporters are mainly traders, who use either bicycles or vehicles to transport milk. However, some transporters are paid by farmers only for collecting milk from the farm and then taking it to the collection center or to a retailer. These transporters supply milk from small farmers to milk shops or directly to consumers. Those with vehicles sell milk to processors, direct from the collection centers. Milk retailers consist of bicycle milk traders selling milk from door to door, milk shops selling only milk or tea, and ordinary shops selling milk alongside other household products. TechnoServe (2008) estimated the profit margin within each node of the dairy value chain to be as follows: 15% for input providers, 62%-28%-44% for dairy farmers depending on how cows are fed respectively open- semi- zero- grazing, 15-25% for transporters, 6% for cooling system owners, 16% for processors, 10% for sellers of raw milk and 15-20% for supermarkets. To date, the dairy value chain in Rwanda has been scattered; nevertheless an organized structure is in the process of being established. PADEBL began a reorganization of the dairy industry in 2009 by setting up some milk collection centers equipped with cooling systems. However, thus far, the number of MCCs equipped in this way has remained below the level needed.

5. Milk development strategies

13The Rwandese government development program, Vision 2020, aims to transform agriculture from a subsistence level to a productive, high-value, and market-oriented farming industry, which is environmentally friendly and has an impact on other sectors of the economy (RARDA, 2011). In this regard, a new value chain will take into account the quality of milk along the value chain. Vision 2020 takes into account the growing pace of the Rwandese economy in general as well as the Livestock sub-sector, focusing on the target of exporting dairy products. Consequently, the Livestock sub-sector will set up a developmental program. It will also accelerate the restructuring of the dairy industry in the whole country with regard to the cold chain, as milk is a very temperature sensitive product. At the same time, distributing and trading milk in ordinary plastic material and on bicycles will be prohibited. The establishing of MCCs in all the dairy basins of the country is seen as the best solution. Mobile cold storage system respecting HACCP standards may replace the current set of standards for milk transport. Establishing cold-storage systems on farms will provide another solution in the fight against microorganisms that pose a threat to human health. Escherichia coli, Listeria monocytogenes, and Salmonella are destroyed by pasteurization or by simple boiling. However, microorganisms such as Staphylococcus aureus, despite being killed by pasteurization, are still harmful due to the toxins they produce. Thus, the protection system close to the farm must be based on a strategy of prevention. RBS must assist with the implementation of standards from the cow on the farm to the consumer. All these measures will be made possible by improving firstly, cattle breeding, genetics and nutrition and secondly, standards of milk preservation, storage, packaging and transportation. For that purpose, a business plan for the period 2008 to 2020 has been established as part of a dairy developmental program introduced by the Livestock sub-sector, based mainly on the identified dairy basins. The new structure of the Livestock sub-sector has served to highlight the targets fixed from 2008 to 2020 in this dairy development program, aimed at stimulating the development of a modern livestock industry in Rwanda through sustainable growth, increasing value added, and access to markets. Five pillars have been identified for the support of this program (Umar et al., 2011):

14– community livestock infrastructure support;

15– public livestock infrastructure support;

16– support for the “One cow per poor family” program;

17– support for productivity enhancing technologies;

18– capacity building.

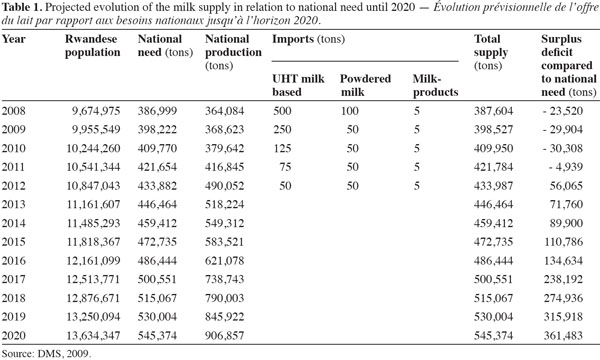

19The program has planned certain objectives, with Rwanda being exporters of milk and milk by-products (Table 1) by 2020. The program will set up further milk collection centers, livestock watering systems and markets, veterinary clinics and quarantine stations in all dairy basins. Poor families will benefit from having cross-breed heifers to support food security and income generation. Training in genetic and feeding techniques will be provided for staff and farmers in the livestock industry, in the form of study tours, short courses, seminars, conferences and workshops. The ultimate goal is the integrated development of the dairy industry (DMS, 2009) in which all stakeholders must play a role in coordinating the production, processing and distribution of high quality milk and its by-products.

6. Conclusion

20Little research has been conducted on kivuguto. In the present paper, the traditional technology used to make this fermented milk as well as its by-products has been described. The dairy industry in Rwanda has also been discussed. Proposed improvements in the development of milk production and the dairy sub-sector in Rwanda at all levels and with all stakeholders have been outlined. Information provided on the value of the whole dairy chain raises some interesting issues in terms of trade in Rwanda and in the region. This study is part of a global research project on kivuguto milk, with the aim of producing this foodstuff in industry.

21Acknowledgements

22The authors are grateful to the University of Liege, Gembloux Agro Bio-Tech, the National University of Rwanda, the CUD (Commission Universitaire pour le Développement) for financial assistance, Dr Tharcisse Seminega and Dr Juvenal Higiro for final reading.

Bibliographie

Abdelgadir W.S., Hamad S.H., Moller P.L. & Jakobsen M., 2001. Characterization of the dominant microbiota of Sudanese fermented milk Rob. Int. Dairy J., 11, 63-70

ADB (African Development Bank), 2000. Dairy cattle development support project. Republic of Rwanda. Appraisal report. Tunis: ADB.

Adekunle J., 2007. Culture and custom of Rwanda. Santa Barbara, CA, USA: Greenwood Publishing Group.

DMS (Development & Management Solutions), 2009. Updating the master plan of milk chain in Rwanda. Kigali: MINAGRI.

Feresu S.B., 1992. Fermented milk products in Zimbabwe. In: Applications of biotechnology to traditional fermented foods. Washington, DC: National Academy Press, 80-85.

Gadaga T.H., Mutukumira A.N., Narvhus J.A. & Feresu S.B., 1999. A review of traditional fermented foods and beverage of Zimbabwe. Int. J. Food Microbiol., 53, 1-11.

ISAR (Institute of Agronomic Sciences of Rwanda). http://www.isar.rw/spip.php?rubrique, May 2010.

Isono Y., Shingu I. & Shimizu S., 1994. Identification and characteristics of lactic acid bacteria isolated from Masaï fermented milk in Northern Tanzania. Biosci. Biotechnol. Agrochem., 58, 660-664.

Karenzi E. et al., 2012. Fermentation of kivuguto, a Rwandese traditional milk: selection of microbes for a starter culture. Sci. Technol. C, 36, 9-17.

Mathara J.M. et al., 2004. Isolation, identification and characterisation of the dominant microorganisms of kule naoto: the Masai traditional fermented milk in Kenya. Int. J. Food Microbiol., 94(3), 269-278.

MINAGRI (Ministry for Agriculture and Animal Resources), 2009. Strategic plan for agricultural transformation in Rwanda. Kigali: MINAGRI.

MINAGRI (Ministry for Agriculture and Animal Resources) & NEPAD (New partnership for Africa's development), 2007. Long-term framework for the implementation of the comprehensive Africa agriculture development program (CAADP). Guiding the economic development and poverty reduction strategy and supporting the strategic plan for agricultural transformation. Kigali: MINAGRI.

Modderman A.M.L., 2010. Dairy cooperatives in Musanze district, Rwanda. A research to explore future prospects for three dairy cooperatives in the Musanze district, Northern Province of Rwanda. PhD thesis: University of Applied Sciences Van Hall Larenstein (The Netherlands).

Mutukumira A.N., 1996. Investigation of some prospects for the development of starter cultures for industrial production of traditional fermented milk in Zimbabwe. PhD thesis: Department of Food Science, Agricultural University of Norway, Aas (Norway).

NISR (National Institute of Statistics of Rwanda), 2010. National Agricultural Survey 2009. Kigali: NISR, http://statistics.gov.rw/index.php?option=com_content&task, (September 2011).

Nzigamasabo A. & Nimpagaritse A., 2009. Traditional fermented foods and beverage in Burundi. Food Res. Int., 42, 588-594.

PADEBL (Dairy Cattle Development Support Project), 2011. Dairy Cattle Development Support Project. Kigali: MINAGRI, http://www.amis.minagri.gov.rw/fr/node/77/5331, (October 2010).

Porter M.E., 1998. Competitive advantage: creating and sustaining superior performance. New York, NY, USA: Free Press Editions.

Rutamu I., 2008. Investment opportunities in the dairy sub-sector of Rwanda. SNV (Netherlands development organisation) & IFAD (International fund for agricultural development) report. Kigali.

Tantaoui-Elaraki A. & El Marrakchi A., 1987. Study of Moroccan dairy products: lben and smen. Mircen J., 3, 211-220.

TechnoServe, 2008. Dairy value chain in Rwanda. A report for the East Africa Dairy Development Program. Washington, DC: TechnoServe.

Umar L. et al., 2011. Livestock infrastructure support program (Sector budget support). Appraisal report. Tunis: African Development Fund.