1 Introduction

Moving towards sustainable processes is a mandatory task to realize greener components for the automotive industries [1]. This is especially true as these components are used in eco-friendly products such as electric vehicles (EVs) [2]. However, as well known, the efficiency of EVs is limited mainly due to the high weight of batteries. A method to improve the kilometric range of EVs is to lighten structural and non-structural components [3]. In this context, CFRP (Carbon Fiber Reinforced Polymer) composites, due to their impressive resistance-to-weight and stiffness-to-weight ratios, are increasingly attracting the attention of car manufacturers as valid replacements for metals [4, 5]. Moreover, different studies demonstrated that the use of CFRP in substitution of steel for the production of car structures, in a life cycle perspective, can lead to a reduction of environmental impacts, especially if long lifetime is assured [6, 7]. This can be attributed to the lowest fuel consumption of the vehicle realized in composite materials even though their manufacturing and the EoL (End of Life) phases result in higher impacts respect to the ones of steel [8]. Indeed, CFRP composites (especially those based on thermoset matrix) cannot be recycled and their production processes require significant quantities of energy.

According to literature, the production of raw carbon fibers can account for more than 50% of the total environmental loads of the manufacturing of a CFRP product [9]. However, an important share of these impacts is related to the manufacturing processes exploited to realize composite components. Indeed, to consolidate thermoset matrix and to obtain the higher mechanical performances, composites are cured at high temperature and pressure, thus requiring an intensive use of energy carriers.

One of the most used manufacturing techniques for producing high performance CFRP products is vacuum bag molding with autoclave curing. It needs long lay-up and curing times, as well as high manufacturing costs. In addition, this process is related to high environmental loads as compared to other manufacturing techniques [6, 10].

OOA (Out-Of-Autoclave) methods allow to overcome the above-mentioned limitations of autoclave curing. As an example, dry fibers technologies such as Resin Transfer Molding (RTM) have been recognized as valid alternative methods to produce high performance composite components. To shorten processing time, injection pressure can be increased, thus performing High-Pressure RTM (HP-RTM) instead of Low-Pressure (LP-RTM) and Compression (C-RTM) RTM [11–13]. However, to do that, heavier and more expensive equipment (such as molds, pumps, presses, etc.) are required. From the environmental point of view, this results in an increase of the environmental loads [14].

Another OOA method which is gaining the attention of industries is PBM (Pressure Bag Molding) [15]. Using this method, it is possible to reduce the cycle time of at least 30% respect to the autoclave process. However, as reported by Vita et al. [16], PBM could results in higher environmental impacts respect to vacuum bag molding with autoclave curing as CFRP molds are used.

All of the aforementioned processes allow to produce high performance composite components. However, in literature no researches are found concerning the comparison of these manufacturing techniques from an environmental point of view. For this reason, in this paper, vacuum bag molding with autoclave curing, PBM, HP-RTM, LP-RTM and C-RTM are compared analyzing the environmental loads related to each process in a life cycle perspective, according to ISO 140044 and 14040. A reference CFRP component for the automotive industry has been considered to assess the environmental aspects associated to all the phases of the different techniques, from raw material extraction to the end of manufacturing.

2 Process variants description

In this study five different production processes were compared from an environmental point of view: Low Pressure-RTM (LPRTM), High Pressure-RTM (HP-RTM), Compression-RTM (C-RTM), Pressure Bag Molding (PBM) and vacuum bag molding with autoclave curing.

RTM is a closed-mold process as reinforcing dry fibers are placed inside a closed mold before the injection of a liquid thermoset resin. The mold is heated to the adequate temperature that allows the matrix curing. LP-RTM is a modification of the conventional RTM process, the less expensive one in terms of equipment used. It employs lower resin injection pressure and final hydrostatic pressure during the curing cycle. Vacuum is used to clamp molds and helps the resin flow across the fiber pack. The standard cycle time has a duration of 30-60 minutes, considering the typical injection pressure of 10-20 bars [12]. HP-RTM is able to reduce cycle times to less than 10 minutes using injection pressures up to 150bars. These pressures cause high tooling costs and movements of dry fibers inside the molds (a binder is used to hold the fibers in position) [17]. C-RTM further reduces cycle times (injection and impregnation) respect to the HP-RTM. During the injection phase, a gap is present between the dry preform and the countermold, which gives less resistance to the resin flow. The injection pressure is typically equal to 5-10 bars [13].

The autoclave processing is performed laminating a preimpregnated material, prepreg, on a CFRP mold. Then, a vacuum bag is realized and the curing occurs in an autoclave at high temperature and pressure for long time, typically more than 100°C, 2 bar and 2 hours, respectively. The CFRP mold is realized stacking prepreg sheets over a plastic master, typically made of a polyurethane foam (Ureol®) and performing a complete vacuum bag process with autoclave curing. The useful life of a plastic master is 10 uses and then disposed in landfills, while the mold can be used, before surface degrades, for 150 times [18].

In the PBM process, a silicone counter-mold, manufactured by a curing reaction in an oven, is used to consolidate the CFRP prepreg sheets, laminated over a mold, at a pressure of 6-8bar. The mold is typically made of aluminum and heavy mass is required to withstand the high press pressure generated by a press and by the countermold. The demolding phase requires an energy intensive cooling system [15].

3 Life cycle assessment

The Life Cycle Assessment methodology has been used to assess and compare the five different process alternatives. Analyses have been conducted by following the methodology and guidelines foreseen in the ISO 14040 – 14044 standards, which includes four steps: (i) Goal and scope definition, to define objective, functional unit and system boundaries; (ii) Life Cycle Inventory (LCI),

to “decompose” the system under analysis in different unit processes and perform an input-output analysis; (iii) Life Cycle Impact Assessment (LCIA), to calculate the impact in terms of different impact and damage categories; (iv) Results Interpretation, to analyze the obtained results, identify criticalities and define possible improvement strategies.

The Simapro 8.0.5.13 software tool, which includes the Ecoinvent 3.1 as database for secondary data, has been used to model the analyses and calculate the results.

3.1 Goal and scope

The objective of the study consists in comparing the environmental impacts of five process alternatives for the manufacturing of CFRP components for the automotive sector: (i) Autoclave; (ii) Pressure bag molding; (iii) Compression resin transfer molding; (iv) High pressure resin transfer molding; (v) Low pressure resin transfer molding. The study can be useful for manufacturing companies involved in the CFRP sector in order to choose the best process alternative to pursue environmental sustainability of their manufacturing activities.

The part considered in the study is a fender of a high-performance sport car with a surface of about 1,3 m2 and a weight of the finished part of about 1 kg. Despite the five different process alternatives, generally lead to parts with different mechanical properties (parts manufactured through autoclave processes have the best performances followed by PBM and then RTM), in this case the CFRP fenders can be considered comparable from the LCA point of view since no advanced mechanical performances are required, and its adoption in sports car are only related to vehicle lightweighting strategies (i.e. substitution of metal parts). Therefore, the common functional unit can be defined as “the production of a CFRP fender with the abovementioned dimensions, through different manufacturing processes”.

The study can be classified as a cradle to gate analysis, since all the unit processes from material production to manufacturing of the finished part have been analyzed, while distribution, use in the car and end of life are not included in the study. The impact assessment methods have been chosen by considering the most relevant impact and damage categories for the CFRP sector, according to previous literature studies [10, 19–21]:

• ReCiPe midpoint [22] to calculate the impact in terms of 18 different categories in order to have a comprehensive overview about the environmental performance of the system under analysis;

• ReCiPe endpoint [22] to normalize and weigh the 18 midpoint indicators, obtaining results in terms of three damage categories (i.e. Ecosystems, Resources, Human health) and finally an aggregated single score.

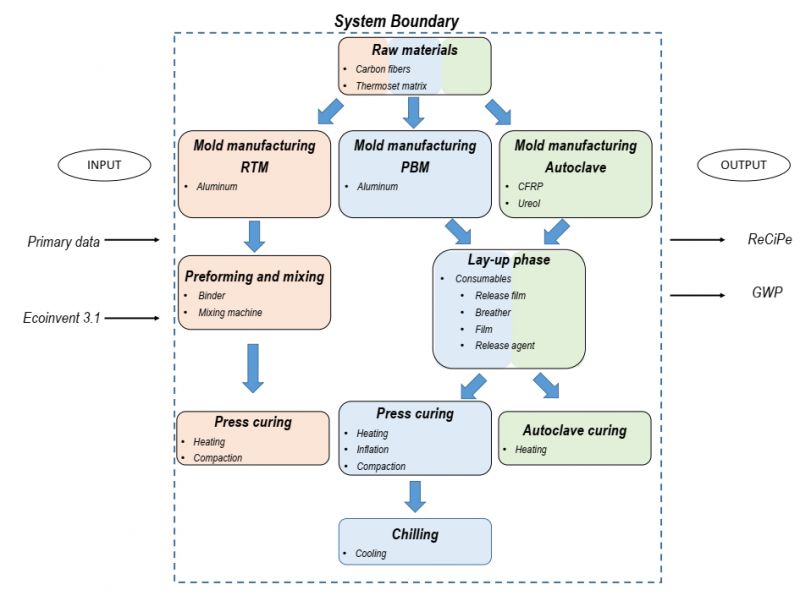

A graphic explanation of the presented manufacturing processes and the relative system boundary is reported in Fig. 1.

Fig. 1: The investigated manufacturing processes and the relative manufacturing phases.

3.2 Life cycle inventory

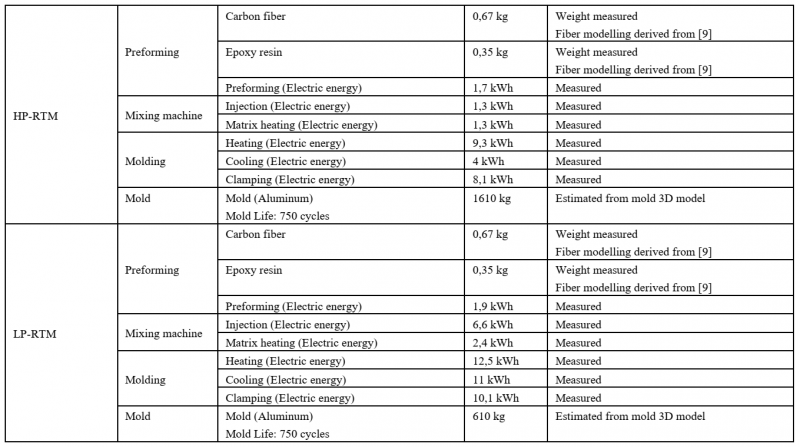

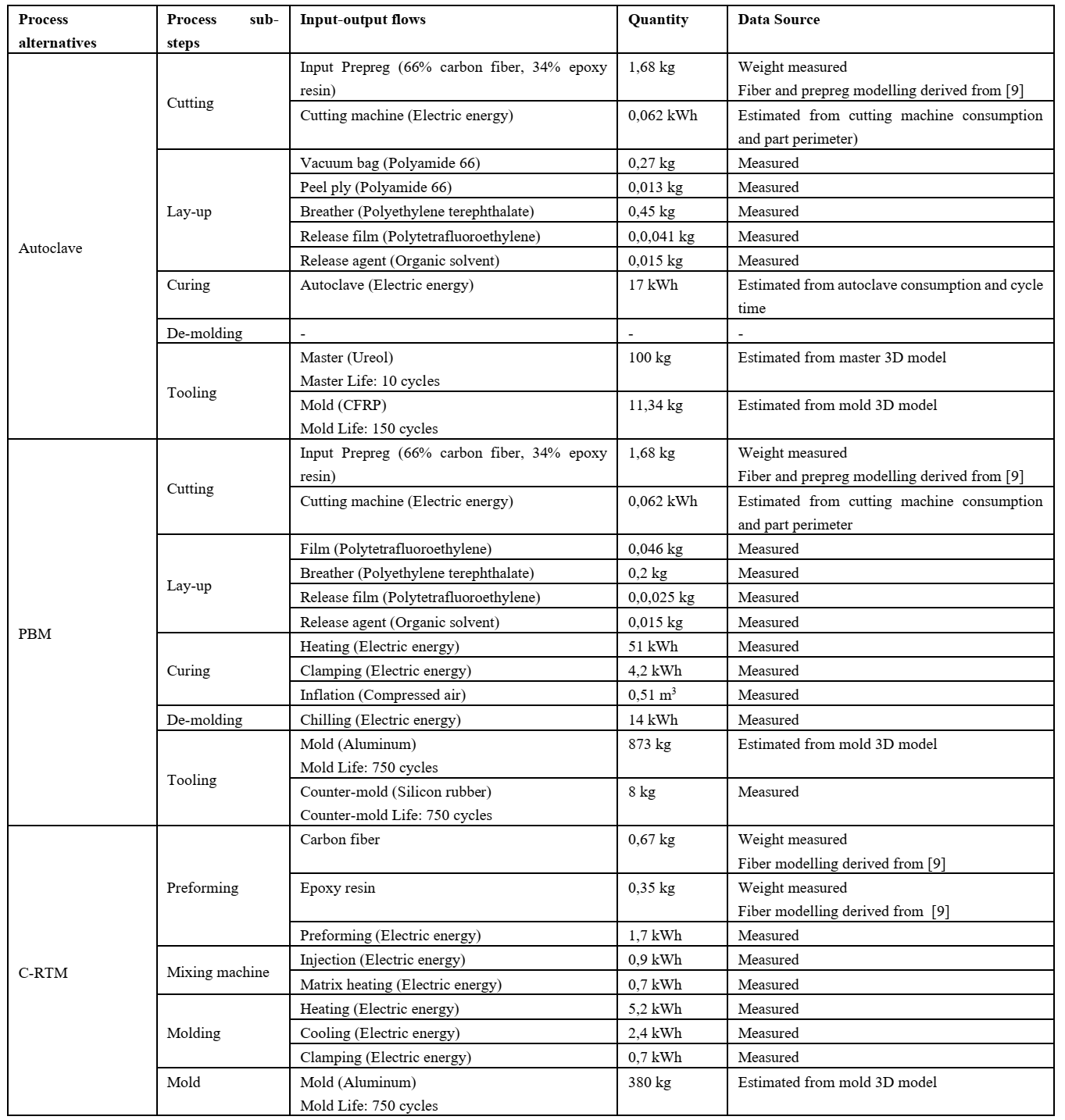

The LCI is based on measured and estimated data, as well as data derived from relevant literature studies. The following Table 1 reports the full inventory data used in the LCA, together with the details about the data sources.

Table 1. Inventory data

3.3 Results assessment and interpretation

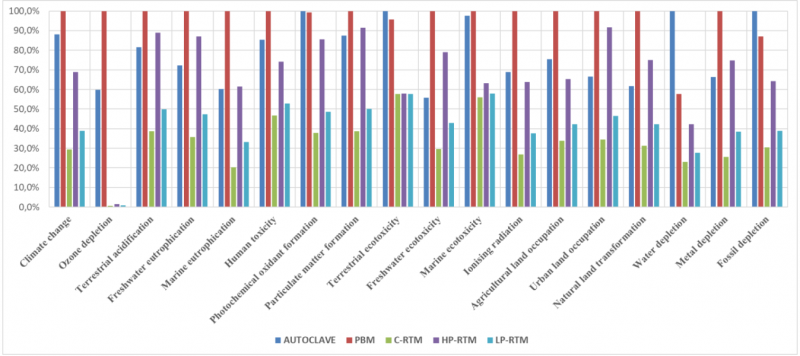

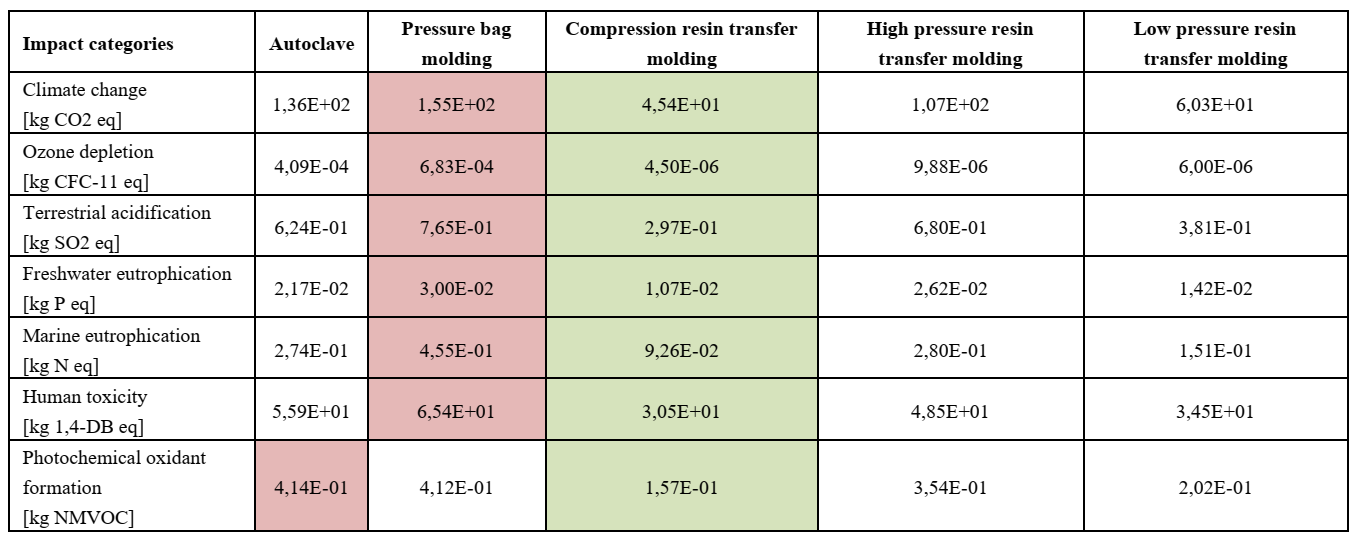

The first Life Cycle Impact Assessment (LCIA) has been performed by jointly considering all the midpoint indicators included in the ReCiPe methodology. The following Table 2 reports the results obtained for each CFRP manufacturing process, with the indication of the best (green cells) and worst (red cells) alternatives for each impact category. For the purpose of comparison, Fig. 2 reports a normalized comparison to highlight the percentage saving of each alternative in comparison with the worst alternative in each impact category. The applied normalization consists in dividing the obtained results in each impact category by the maximum results obtained.

In this way the worst alternative has a 100% value and the savings can be easily visualized.

Table 2. ReCiPe midpoint categories results

Fig. 2. ReCiPe normalized comparison

From the ReCiPe midpoint analysis, the clearest conclusion is related to the best process alternative: regardless of the considered impact category, the most sustainable process is the C-RTM. The savings against the worst alternatives are relevant and range from 42,4 %, in case of Terrestrial ecotoxicity, to 99,3% in case of Ozone depletion. The worst alternative, instead, is almost always the

PBM process, except for Photochemical oxidant formation, Terrestrial ecotoxicity, Water depletion and Fossil depletion where the worst alternative is the Autoclave process. Leaving aside the first two indicators for which the differences among the PBM and Autoclave are minimal, for the other two impact categories the results are mainly due to the use of a large amount of Ureol to manufacture the master in case of Autoclave. Comparing the three RTM variants, the results highlight that C-RTM is always the best alternative, LP-RTM is an “intermediate” solution, while HP-RTM is always the worst process variant. For some of the ReCiPe midpoint categories (i.e., Terrestrial acidification, Freshwater eutrophication, Marine eutrophication, Particulate matter formation, Freshwater ecotoxicity, Urban land occupation, Natural land transformation, Metal depletion) this latter globally represents the second worst alternative. In all the cases the main reasons are the use of large quantities of aluminum to manufacture the mold and the high consumption of electric energy for heating, cooling and clamping during the molding phase.

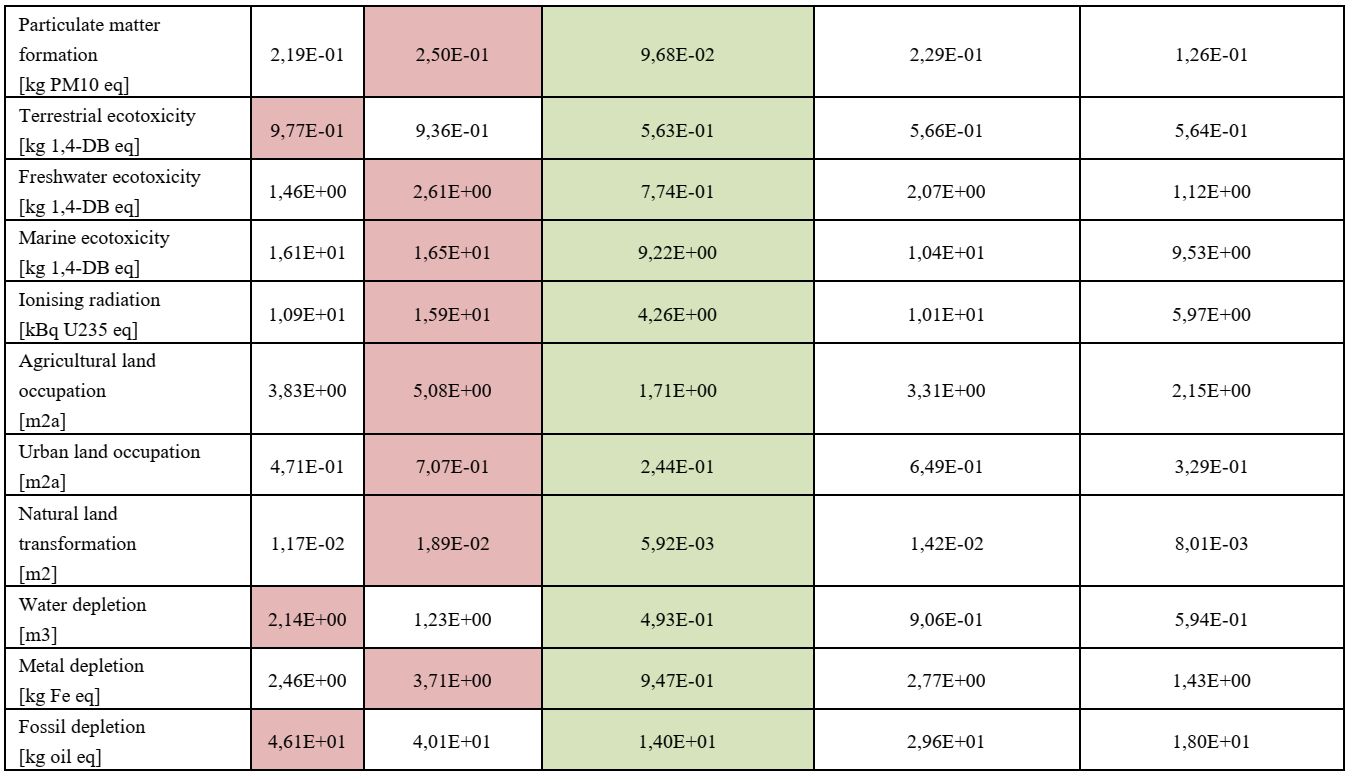

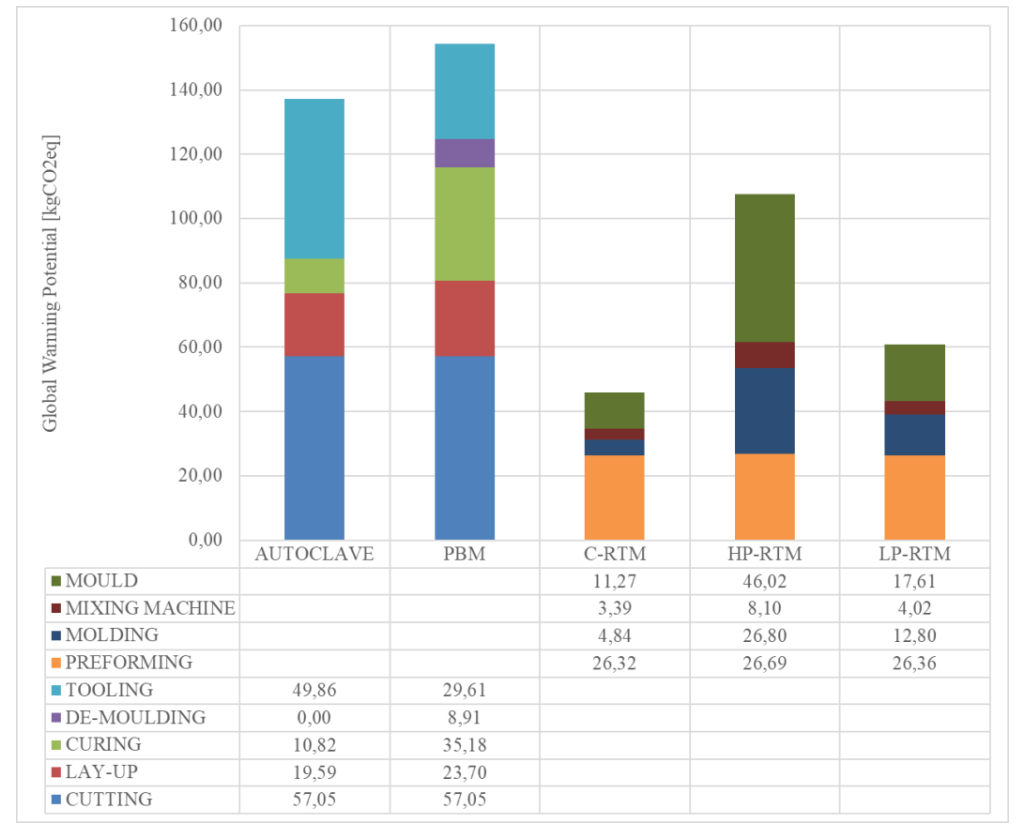

Going into more details in one of the most relevant categories for the manufacturing sector, and in particular for CFRP [10, 19–21], the following Fig. 3 reports the split of contributions for the Global Warming Potential indicator (i.e. ReCiPe Climate Change). In this case the best alternative is the C-RTM, followed by the LP-RTM, the HP-RTM, the Autoclave, and finally the PBM as the most impactful process. Split of contributions highlight that for almost all the process the most critical flow is the production of carbon fibers, included within the Cutting contribution for Autoclave and PBM, and Preforming for the three RTM variants. However, there is a substantial difference among Autoclave/PBM, where Cutting contributes for 57,05 kgCO2eq, and RTM variants, where Preforming contributes for less than a half, 26,32 kgCO2eq. The main reason of this large difference is the major efficiency of the RTM process in the use of carbon fibers, because in case of Autoclave/PBM the prepreg sheets have to be cut with the generation of large amount of scraps, while in case of RTM the scraps are almost null. This is confirmed by the inventory data reported in Table 1, where for Autoclave/PBM processes the input carbon fibers are about 1,10 kg (66% of 1,68 kg of prepreg), against only 0,67 kg in case of RTM processes. Another minor cause is the use of dry fibers in case of RTM, instead of prepreg, in case of Autoclave/PBM, which requires consumption of energy for the prepregging phase [9].

Considering Autoclave, the second largest contribution is the Tooling (about 36% of the total impact), that is mainly due to the manufacturing of the Ureol master (more than 90% of the Tooling contribution). For PBM, the contribution of Tooling is relevant but minor than in case of Autoclave (29,61 vs 49,86 kgCO2eq). The most penalizing contribution is certainly the Curing, and specifically the critical flow is the energy consumption for heating the mold. In addition, in this case also the De-molding phase generates impacts due to the energy consumption needed for cooling the mold before the part extraction. Such two contributions make the PBM the worst process in terms of GWP.

Considering RTM, instead, the different dimensions of aluminum molds for the three variants (380 kg for C-RTM, 1610 kg for HPRTM and 610 kg for LP-RTM) cause relevant differences in terms of GWP impacts (46,02 kgCO2eq, 17,61 kgCO2eq and11,27 kgCO2eq, respectively). In addition, the mold dimensions are directly correlated to the electric energy needed for mold heating during the resin curing, another aspect that enlarge the differences among C-RTM, LP-RTM and HP-RTM (in order of total impact).

Fig. 3. Split of contributions in terms of Global Warming Potential midpoint category.

Fig. 3. Split of contributions in terms of Global Warming Potential midpoint category.

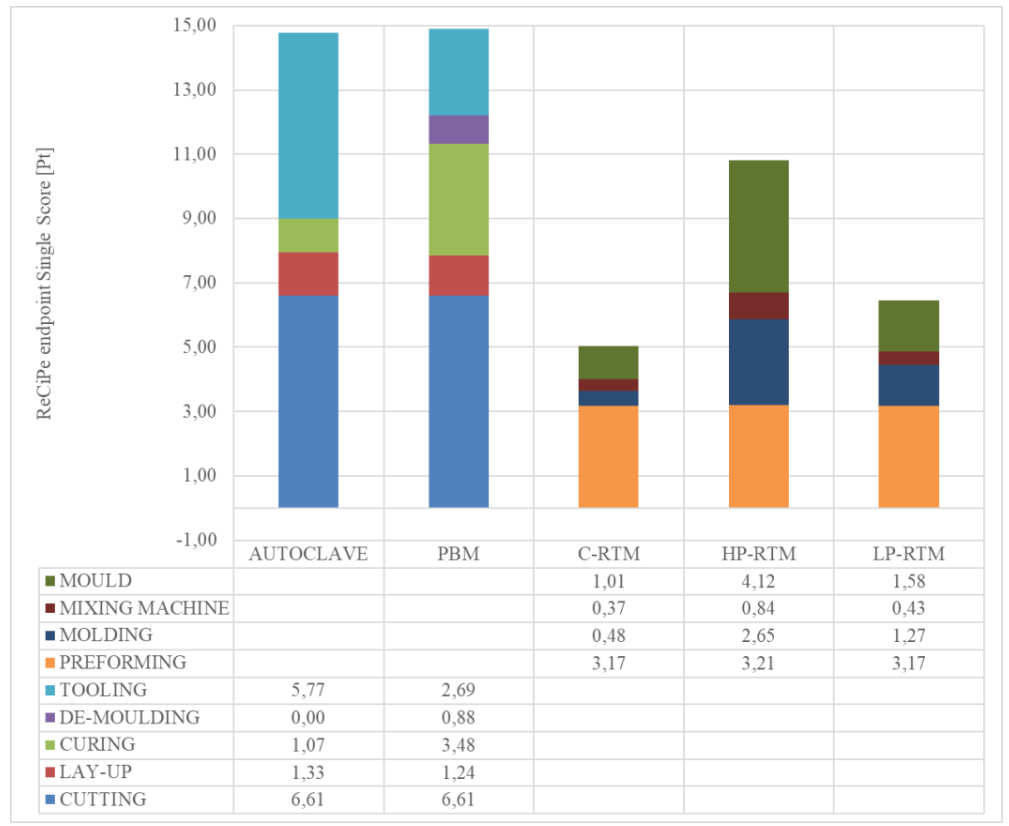

Finally, a ReCiPe endpoint analysis has been performed, as reported in the following Fig. 4. As expected, the worst alternatives are PBM and Autoclave for which about the same impacts have been obtained (14,90 Pt for PBM vs 14,78 Pt for Autoclave): the savings for Curing in Autoclave vs PBM (1,07 vs 3,48 Pt) are “compensated” by the largest impacts for the Tooling (5,77 vs 2,69 Pt). Once again, the RTM variants demonstrated to be more sustainable processes, in line with the results previously obtained with the ReCiPe midpoint analyses.

Fig. 4. Split of contributions in terms of ReCiPe endpoint Single Score

Fig. 4. Split of contributions in terms of ReCiPe endpoint Single Score

4 Conclusion

In this research, five manufacturing processes for the obtaining of CFRP components have been compared from the environmental point of view. One process is bag molding with autoclave curing and the others are three RTM variants (High Pressure, Low Pressure and Compression) and pressure bag molding (PBM). The reported LCA analyses include all the phases from raw materials extraction

to the end of the manufacturing process of a typical component for the automotive industry.

The obtained results show that:

• The manufacturing of carbon fiber and epoxy resin is the most relevant environmental load for the analyzed processes;

• RTM techniques are associated to lower environmental impacts with respect to both PBM and autoclave;

• C-RTM results the greener manufacturing process, mainly due to the lightness of the mold;

• Autoclave and PBM are the worst processes. This can be attributed to the prepregging phase and to the high impacts related to the manufacturing of aluminum and CFRP molds as well as of the Ureol master.

7