1 Initial Situation and Motivation

Stainless steel is crucial for many application fields as an alternative for corrosive applications, showing a growing volume of 3 – 5 % p.a. [1]. Its non-corroding properties are important e.g. for industries with high hygiene standards such as medical and nutrition industries, but also for applications with aggressive environmental influences such as naval ship building or offshore wind power drives. It is increasingly used in energy and nuclear sector [2]. One of the first developed stainless steels (Krupp Company, Germany, 1912) is up to now amongst the most frequently used stainless steel alloys [3]. It is known under the compositional name X5CrNi18-10 (AISI 304) or the material number 1.4301, which is the first number in the class of stainless steels. The material was formerly known as V2A (short for “Versuchsschmelze 2 Austenitisch”, experimental melt 2 austenitic). X5CrNi18-10 is not a high-strength steel per se but becomes difficult to process due to the high hardness of the martensite phase, known as transformation-induced plasticity (TRIP) effect. In general, work hardening is of advantage for using favorable property combinations of ductility and strength, but in the case of X5CrNi18-10, this effect complicates the processing on account of high hardness. Due to the importance of this material, its processability is of utmost importance. Thus, it is desirable to investigate the fine blanking properties of this steel. A large number of investigations have been dedicated to X5CrNi18-10 both in general and focused on forming technology. For instance, BAY investigated the material as part of a tribological system for forming [4]. ERIKSSON and OLSSON conducted research on the galling resistance of X5CrNi18-10 sheet material using pin-on-disc testing [5]. HETZNER ET AL. investigated the local adjustment of tribological properties for so-called sheet bulk metal forming processes especially of X5CrNi18-10 [6]. DANIEL ET AL. did research on the lifetime of PVD coatings of fine blanking punches with X5CrNi18-10 sheet material [7]. NEUGEBAUER ET AL. investigated the influence of a pre-defined load on the precision cutting process of X5CrNi18-10 sheet material [8]. In terms of punching, ARSLAN and ÖZDEMIR presented research on punch wear at punching X5CrNi18-10 [9]. EMONTS investigated punching with laser heating support [10]. Fine blanking faces, due to the different tool concept and process guidance, different parameters and output than punching. A promising approach, however, to mitigate many challenges of the fine blanking process is inductive heating prior to the fine blanking process [11]. The fine blanking of inductively heated X5CrNi18-10 sheet metal has not been subject of systematical research yet, though the process window lies within distinct boundaries [12].

2 Scientific Problem and Materials

The objective of this research is the experimental investigation of process forces and part quality for fine blanking of stainless steel with inductive heating. The interactions between metal sheet temperatures in the moment of cutting and process forces are to be investigated as well as the changes of the part quality in terms of dimensional accuracy, die roll and cut surface state.

The elemental composition of X5CrNi18-10 is of utmost importance for fine blanking. The compositional name suggests 0.05 % C, 18 % Cr and 10 % Ni. In Table 1, the composition of X5CrNi18-10 is given more in detail according to the standard DIN EN 10088-2 [13]. In the previous section, the importance of the elemental composition of X5CrNi18-10 and its consequences for the fine blanking process have been explained. As the elemental composition of the specimens is of high importance, they were investigated using optical emission spectroscopy. The results can be found in Table 1.

Table 1. Elemental composition of the X5CrNi18-10 specimens determined by optical emission spectroscopy in comparison to the nominal values as defined in the standard DIN EN 10088-2 [13]

As can be seen in Table 1, the specimens do consist of X5CrNi18-10, correspond to the standard and are suitable for forming as a consequence of the relatively high portion of austenite stabilizing elements Cu and Ni. It has to be considered that the results of optical emission spectroscopy are in general less accurate than the results of the melt composition analysis. Furthermore, after an annealing process, some elements as Sulfur tend to appear increased in comparison to the melt composition analysis depending on the annealing process, as optical emission spectroscopy only investigates the surface of a specimen. The mechanical properties were tested in tensile tests and were determined as Rp0.2 = 271 MPa and Rm = 608 MPa.

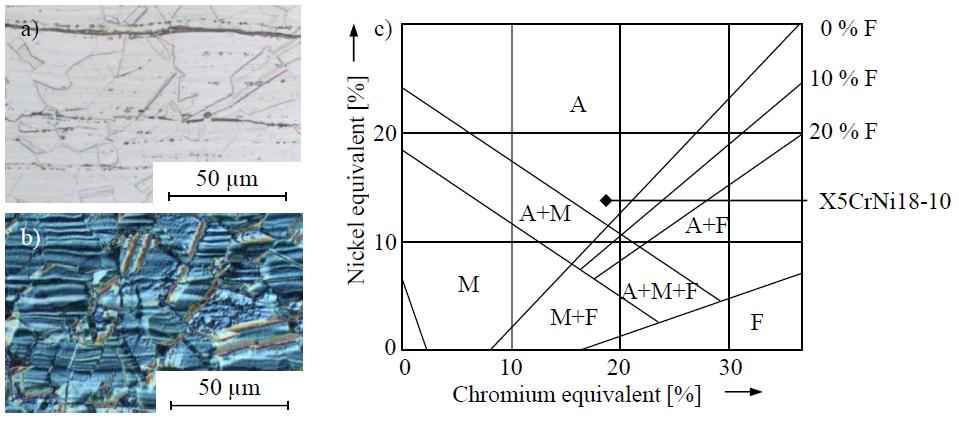

The importance of the elemental composition as presented in Table 1 lies in the specific properties of X5CrNi18-10. They are unusual for a steel material: corrosion-resistant, non-ferromagnetic and not hardenable by heat treatment [3]. As a metastable austenite, X5CrNi18-10 can turn to martensite when processed with a forming process. This results in a magnetization of the non-ferromagnetic austenite and, more important for the forming process, in a sudden impact on the forming press known as cutting impact. The metal lattice was investigated by means of metallographic cross-sections and is given, together with the SCHAEFFLER diagram for X5CrNi18-10, in Figure 1.

Figure 1. Cross-section of specimens a) with standard and b) with Beraha II-etching and c) SCHAEFFLER diagram with marking point for X5CrNi18-10. A: Austenite, F: Ferrite, M: Martensite [14]

Figure 1. Cross-section of specimens a) with standard and b) with Beraha II-etching and c) SCHAEFFLER diagram with marking point for X5CrNi18-10. A: Austenite, F: Ferrite, M: Martensite [14]

As can be seen in Figure 1, the specimens show an austenitic metal lattice with some anisotropy. The austenite can be recognized by characteristic twin structures in Figure 1a). The Beraha II-etching in Figure 1b) shows austenite in dark and blue colors. The needle-like microstructure of martensitic parts can not be found in the cross-sections. The anisotropy in horizontal direction is due to the hot rolling process in which the sheet metal was produced prior to the experiments.

The stability of austenite depends strongly on the portion of nickel equivalents in the X5CrNi18-10 alloy, visible in the SCHAEFFLER diagram in Figure 1c). Austenite stabilizing elements are Cu, Ni, Co, and Mn [15]. As a consequence, the bigger the portions of those elements are in the X5CrNi18-10 alloy (within the limits of the standard), the better it can be formed and especially fine blanked, as the risk of turning into martensite diminishes. In conclusion, the specimens are well apt for fine blanking experiments. Cutting impact is not expected to a greater extend, as the peril of martensitization is comparatively low and not enforced by the servomechanical press.

3 Approach

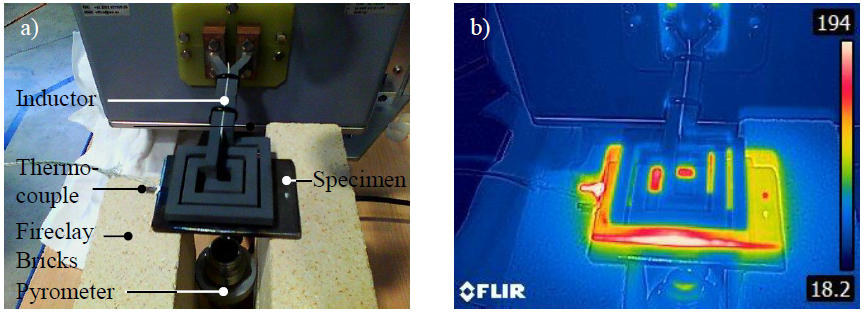

In order to meet the objective of this research, the experiments were performed following the process route of inductive heating and subsequent fine blanking of prepared specimens which has already been described [10]. Due to the specific properties of X5CrNi18- 10, oxidation effects as they do often accompany inductive heating are not expected [16]. The experiments were performed using an iew TTH25 inductive heating device and a servo mechanical Feintool XFT 2500speed servo mechanical fine blanking press at a cutting velocity vc = 50 mm/s. In every experiment, a specimen was heated using the induction heating device, then transferred to the fine blanking press and fine blanking was performed. The temperature measurement included two pyrometers of type Sirius SI23 controlling the inductive heating device. The temperature changes during the experiments were recorded using a thermocouple fixed to each specimen. The heating process is presented in Figure 2.

Figure 2. Inductive heating a) in standard photography and b) in thermal imaging photography with unit °C

Figure 2. Inductive heating a) in standard photography and b) in thermal imaging photography with unit °C

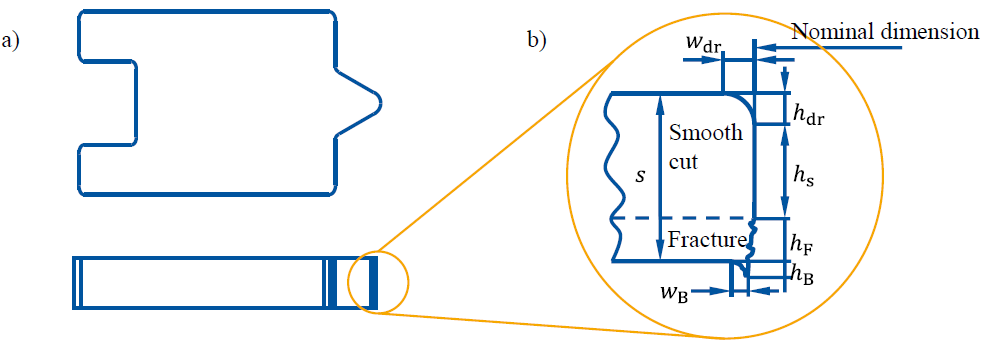

Six different target temperatures between 150 °C and 400 °C in steps of 50 °C each have been investigated, enhanced by reference experiments at room temperature without heating, starting at low temperatures and increasing the temperature step by step. The upper boundary of 400 °C was chosen in order to safely remain below the recrystallization temperature which is expected around 560 °C for X5CrNi18-10. At those temperatures, no recrystallization effects are to be expected [17]. The sheet thickness was s = 6 mm. All experiments have been repeated four times. The process forces have been measured as well as the temperatures. An experimental geometry “arrow part” was used which is specially designed for fine blanking experiments. The quality properties of the fine blanked parts have been measured according to the standard VDI 2906 [18]. This is depicted in Figure 3.

Figure 3. “Arrow part” geometry a) with quality properties b) according to the standard VDI 2906 [18]

Figure 3. “Arrow part” geometry a) with quality properties b) according to the standard VDI 2906 [18]

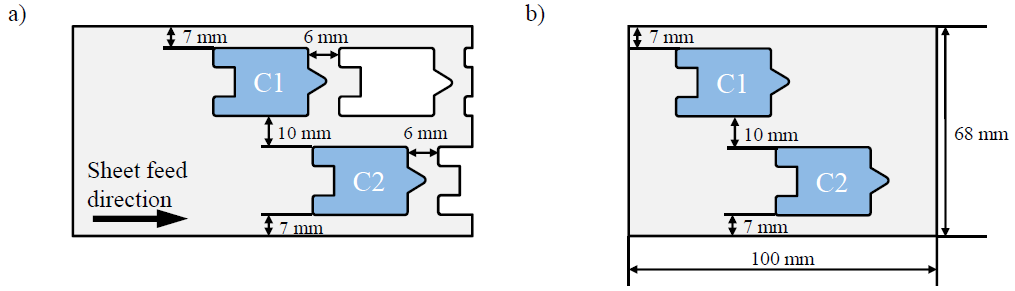

A twofold falling fine blanking layout was used. This layout can be implemented in continuous experimentation or in single-stroke experiments, as it was for this paper. Twofold falling experiments provide the advantage that more parts are available especially for destroying analysis methods and thusly extend the data basis. The fine blanking layout is shown in Figure 4.

Figure 4. Twofold fine-blanking layout “arrow part” for continuous experiments a) and for single-stroke experiments b), which was used for this paper. The fine blanking cavities are referred to as C1 for the rear left cavity and C2 for the right front cavity

Figure 4. Twofold fine-blanking layout “arrow part” for continuous experiments a) and for single-stroke experiments b), which was used for this paper. The fine blanking cavities are referred to as C1 for the rear left cavity and C2 for the right front cavity

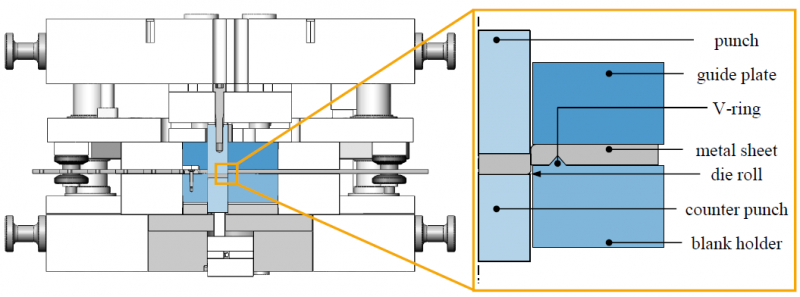

As can be seen in Figure 4, the fine blanking layout does provide enough clearance between the cavities to ensure that there is but little mutual influencing between the fine blanking cavities [19]. All experiments have been performed using the same set of tool elements, i.e. punch, blank holder, counter punch, and guide plate. The tool concept is presented in Figure 5.

Figure 5. Fine blanking tool with detail presentation of active elements and die roll

As can be seen in Figure 5, the tool concept used a standard fine blanking setup consisting of punches, guide plate, counter punches and blank holder. A circumferential V-ring with three gaps was adapted to the blank holder at both cavities.

4 Results

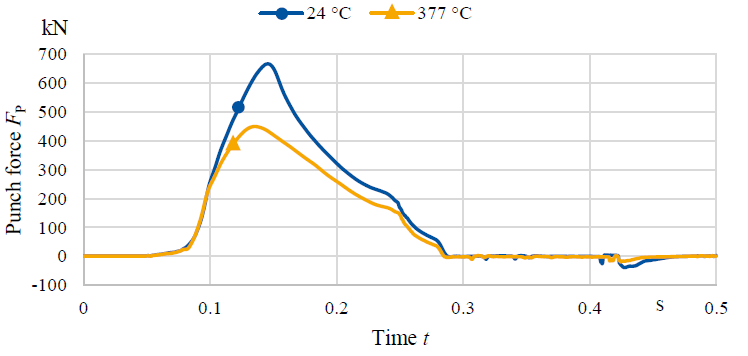

During the experiments, the process forces were measured as a main objective for fine blanking lies in the reduction of process forces with the aim to process high-strength steels in a reliable way. Results for one stroke at cutting temperature Tc = 24 °C and Tc = 377 °C are given in Figure 6.

Figure 6. Punch force curve at cutting temperature Tc = 24 °C and Tc = 377 °C

Figure 6. Punch force curve at cutting temperature Tc = 24 °C and Tc = 377 °C

In Figure 6, several observations can be made. Firstly, the punch forces are reduced at higher cutting temperature. The maximum punch force is diminished by 33 % in comparison to fine blanking at room temperature. Secondly, the course of the punch force is at a higher temperature more homogenous. In general, the punch force shows different sections: closing of the tool (growing punch force), start of cutting (maximum point), cutting (decreasing force, due to the falling cutting resistance as a result of the increasingly thin remaining sheet metal at the cutting line) breaking of the burr (small peak) and subsequent power drop to zero. Hence, the observation is that the punch force shows a more homogenous course during the cutting. For a better understanding, the punch force maxima of all experiments are presented in Figure 7.

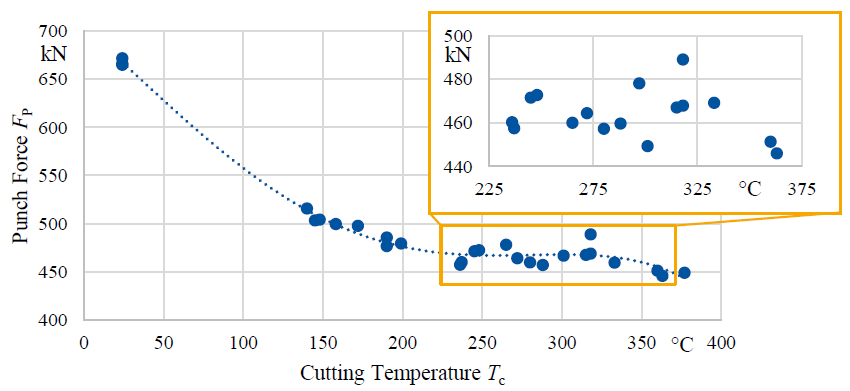

Figure 7. Punch force maxima at different cutting temperatures with polynomic approximation function of 4th grade

Figure 7. Punch force maxima at different cutting temperatures with polynomic approximation function of 4th grade

The development of the punch force maxima as depicted in Figure 7 shows some noticeabilities. Firstly, the punch force maxima do indeed decrease with growing cutting temperature. Secondly, the decrease is considerable and amounts to 33 % lower values at a cutting temperature Tc = 377 °C compared to the room temperature reference. Thirdly, the decrease is not linear, as would be suggested by the temperature terms in JOHNSON-COOK flow stress model [20]. Instead, it shows an asymptotic decrease with a second peak between Tc = 250 °C and Tc = 350 °C. In addition to the process forces, the part quality in terms of dimensional accuracy, die roll, and cut surface state was measured. The first focus of investigation was the macro geometric dimensional accuracy. The results are shown in Figure 8.

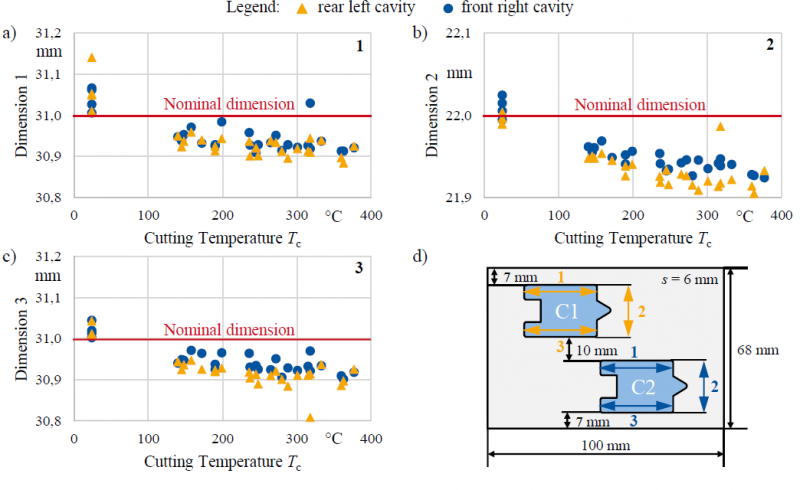

Figure 8. Macroscopic dimensional accuracy, measured at three points and on the two cavities: Dimension 1 - length a), Dimension 2 - width b), Dimension 3 – length, on the opposite side c), and fine blanking layout with visualization of the measuring points d)

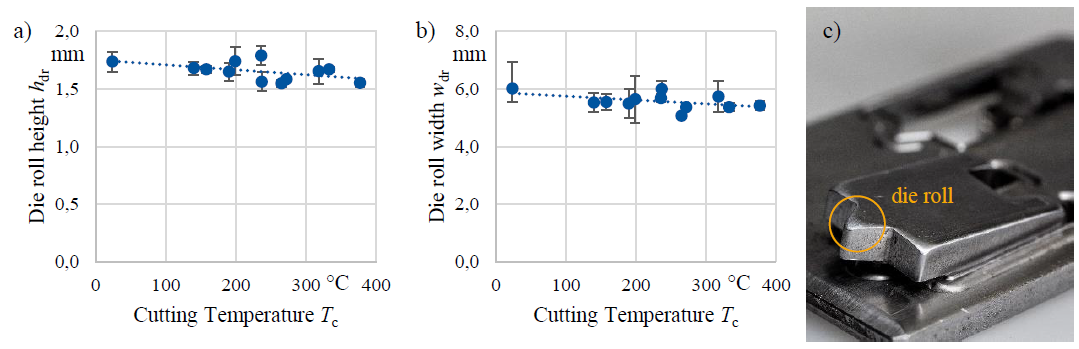

As can be seen in Figure 8, the reference experiments at room temperature generate dimensions slightly above the nominal values. With increasing cutting temperature, the dimensions decrease. In this case, there is no obvious reason to suggest non-linear behavior. In consequence, the values show thermal shrinking, which will, in absence of a justified better assumption, be considered linear. A very important value for assessing fine blanking processes is the die roll [21]. It was measured at the fine blanked specimens using an optical method of structured-light 3D scanning with subsequent comparison to the nominal contour described by VOIGTS ET AL. [22]. The results are given in Figure 9.

Figure 9. Die roll height hdr a), die roll width wdr b) of the fine blanked specimens, with a photography (©Tobias Kaufmann, WZL) with die roll marking c)

Figure 9. Die roll height hdr a), die roll width wdr b) of the fine blanked specimens, with a photography (©Tobias Kaufmann, WZL) with die roll marking c)

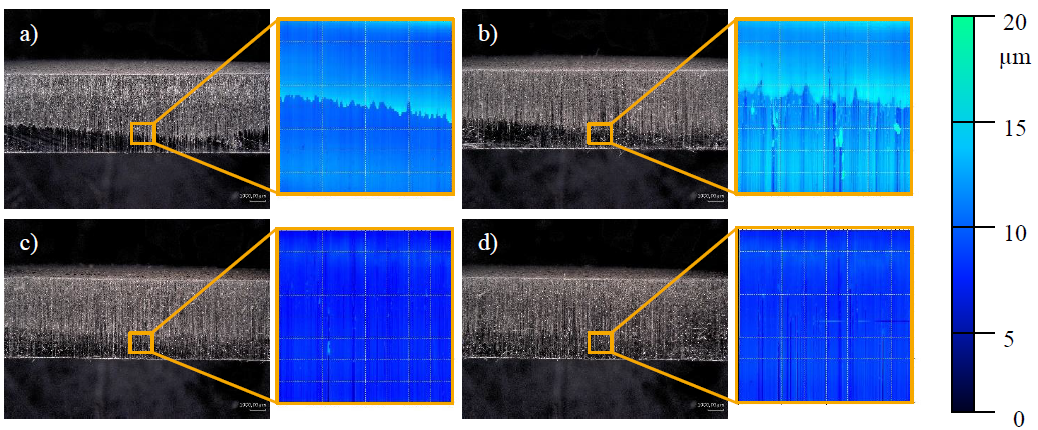

As can be seen in Figure 9, the die roll slightly diminishes with increasing cutting temperature. As a low die roll is a significant quality requirement, heating prior to the fine blanking indicates in this case an increase in part quality. As a last point, the state of the cut surface was investigated using tactile topography measuring and light microscopy imaging. Exemplary results are given in Figure 10.

Figure 10. Light microscopy images of the cut surface (left) and topography measurement (right) at specimens with cutting Temperatures a) Tc = 24 °C, b) Tc = 199 °C, c) Tc = 288 °C, and d) Tc = 377 °C

Figure 10. Light microscopy images of the cut surface (left) and topography measurement (right) at specimens with cutting Temperatures a) Tc = 24 °C, b) Tc = 199 °C, c) Tc = 288 °C, and d) Tc = 377 °C

As can be seen in Figure 10, the cut surface of the specimens, although it shows in each case a smooth cut portion of 100%, is slightly different. What can be seen as a color change in the light microscopy images turns out to be a burr on the surface in a dimension of up to approx. 10 μm height. This phenomenon decreases with growing cutting temperature.

5 Discussion

As described in the previous section, the first observation gained from the experiments is a significant decrease of fine blanking punch forces with increasing cutting temperatures. This is not surprising, as the effect of decreasing mechanical strength with increasing temperatures is well known for steels and e.g. stated by DEHGHAN-MANSHADI ET AL. [24] and KIM and YOO [24] for X5CrNi18-10. However, the decrease does not behave linearly. This indicates that flow models as JOHNSON-COOK do not suffice for a consideration of fine blanking with inductive heating. This was already stated by LIAN ET AL. [25] and can be supported by the results of the experiments performed here. The non-typical behavior of the values of maximum punch force between Tc = 250 °C and Tc = 350 °C can be explained by dynamic strain aging mechanisms. As CHO, YOO and JONAS found out, dynamic strain aging occurs in X5CrNi18-10 primarly between 900 °C and 1,100 °C due to the substitional elements Cr and Ni. Strain aging due to the interstitial elements C and N can, however, occur between 150 °C and 300 °C [26]. NIKITIN stated that a temperature increase of 50 °C suppresses the forming induced martensite formation. Furthermore, he found out that between 200 °C and 500 °C dynamic and static strain aging can occur and stabilize the dislocation structures, activating diffunding atoms of Cr above 400 °C [27].

The part quality increased due to inductive heating. Linear shrinking due to heating has to be taken into account but can be controlled by constructive measures according to PETERLI [28]. Decreasing die roll and decreasing roughness of the cut surface are advantageous in terms of product qualities of fine blanked parts. Furthermore, a general heating of sheet metal minimizes fluctuations of the process temperatures and contributes to reliable and predictable process guidance.

6 Conclusion and Outlook

In conclusion, the following can be stated. Inductive heating of stainless steel sheet metal prior to fine blanking is of advantage. It lowers the process forces and improves part quality as well as process reliability. In the special case of metastable austenitic steel, martensitization can be suppressed by heating. In total, inductive heating prior to fine blanking is a promising approach, which should be investigated further, including more classes of sheet metal.

Acknowledgements

The authors want to thank the German Research Foundation (Deutsche Forschungsgemeinschaft DFG) for the funding of the research work within the project “Erforschung der thermomechanischen Wechselwirkungen in der Scherzone beim Feinschneiden von höherfesten erwärmten Blechwerkstoffen” (KL 500/182-1) and the project “ Erforschung der Wechselwirkungen von einer inkrementellen Randzonenumformung und einer HPPMS-Beschichtung auf Feinschneidstempeln zur Ermöglichung einer belastungsgerechten Einstellung der Oberflächenintegrität“ (BE 2542/14-1). Special thanks go to Andreas Peters for his kind willingness to discuss metal-material relations, to Marcel Botz for his diligent support during the execution of the experiments, to Mario Kittel for the preparation of the cross-sections, to Tobias Kaufmann for the photography in Fig. 8 and to Mirco Trosin and Matthias Marx for the accurate measuring of the specimens.

![Table 1. Elemental composition of the X5CrNi18-10 specimens determined by optical emission spectroscopy in comparison to the nominal values as defined in the standard DIN EN 10088-2 [13]](docannexe/image/2575/img-2-small800.png)