1 Introduction and Objective

Currently, the analysis of the entire life cycle of a product is always closely linked to the emerging greenhouse gas emissions as well as further environmental impacts caused by the extraction of raw material, processing and recycling of the components. Fluctuating raw material prices and dwindling resources pose the risk of serious economic and social conflicts. Resource-efficient production strategies are therefore of great importance. Owing to their high-volume output and good material utilization, forming processes are particularly attractive for the mass production of metallic functional components. These processes are characterized by their superior resource efficiency [1] and provide geometrically complex parts with a wide range of achievable properties. Furthermore, the demand for geometrically complicated, highly durable components with a broad functional density is increasing as a consequence of ongoing mechanization. This often pushes conventional manufacturing processes to their limits. In order to meet the current economic and ecological challenges, a further progression as well as an extension of the process window of forming processes is therefore inevitable. Sheet-bulk metal forming (SBMF), which is characterized by the application of bulk forming operations on sheet metal semi-finished parts, offers an important contribution to this development [2]. Industrial components that can be produced by SBMF are, besides others, seat recliners, synchronizer rings, gear drums or disk gears [3]. Due to the intended three-dimensional material flow in SBMF, functional elements like teeth and carriers can be formed from sheet metal semi-finished parts. In this context, the use of extrusion processes is a promising approach to produce function integrated parts with a short process chain [4].

However, main limitations in the extrusion of sheet metal in SBMF are high forming forces and tool loads, resulting in a restricted die filling for the functional elements [3]. This leads to reduced heights of the functional elements [4]. The manufacturing process of SBMF for producing geared components with involute teeth is subject of current research and aims to provide production strategies for ready-to-use parts. By using a combined numerical and experimental approach, the material flow was analyzed in a forward extrusion process. It was shown, that a radial material flow in the direction of the component center is limiting the die filling for the teeth and carrier elements [4]. As can be seen in Fig. 1, the actual contour of tooth and carrier elements strongly deviates from the targeted contour, resulting in an insufficient filling of the functional elements.

Fig. 1. Comparison of targeted and actual teeth and carrier contours in experimental full forward extrusion.

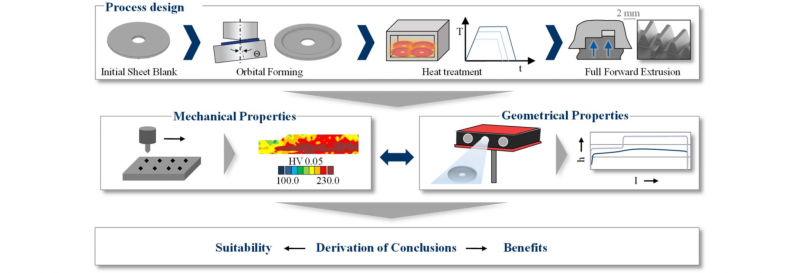

Since manufacturing related, geometric deviations of the involute teeth profile are a main determinant of noise and running characteristics of gears [5], the aim in industrial production is to achieve a high form accuracy. Therefore, measures to avoid the unintended material flow into the workpiece center were established. These include the local adjustment of tribological conditions, the adaption of the process force as well as the variation of the component design [6]. Another promising method to increase die filling is the application of semi-finished products with an adjusted thickness profile. These tailored blanks provide material in the area where it is especially required [7] and can increase the material efficiency by processing a thinner initial blank [8]. Furthermore, the targeted adaption of mechanical properties are to be considered beneficial [8]. Several forming processes and strategies for the manufacturing of tailored blanks are available within SBMF. This study uses an incremental bulk forming process [7] of orbital forming. In this process, the tilted punch leads to a reduced contact area between the workpiece and punch. In comparison to conventional manufacturing strategies of tailored blanks like upsetting, process limits can accordingly be extended and maximum press forces are reduced by up to 90 % [7]. This pre-forming of the sheet blanks however leads to an increase of the material’s hardness [8]. As increasing hardness values have an adverse effect on further forming properties [9], a heat treatment is carried out to restore the initial microstructure and hardness [10]. Similar to multi-stage cold bulk forming processes [9], recrystallization annealing is applied on the tailored blanks. Since the effect of recrystallization strategies on sheet bulk metal forming processes is currently unknown, the objective of the present study is to identify the fundamental effects of heat treatments on the mechanic and geometric properties of the components throughout the whole process chain of a forward extrusion process of SMBF. This enables an extension of the forming limits and thus provides the foundation for further industry-oriented process adaptions. Based on the evaluation of different recrystallization strategies, the benefits of tailored blanks with a varying sheet thickness are evaluated. Four heat treatments with the potential to improve the formability after orbital forming were selected. The developed and applied methodology is shown in Fig. 2.

Fig. 2. Methodology of the present study to assess tailored blanks regarding their feasibility for forward extrusion of SMBF.

To characterize the mechanical properties of tailored blanks manufactured by orbital forming with subsequent heat treatment, the hardness distribution was measured in the area of the material build-up to enable a comparison of the values after the extrusion process. Accordingly, the hardness of the finished parts were also detected in the zone of teeth elements and carriers. All hardness values were obtained according to ISO 14577-1, using the Fischerscope HM2000 from the Helmut Fischer GmbH. Furthermore, a contact-free 3D-scanning device was used to characterize geometrical properties and die filling of the geared components. The microscopic surface integrity of the part surface was moreover characterized by the optical 3D surface measuring device InfiniteFocus from Alicona. These results are subsequently used to derive relations between heat treatment strategies and the resulting mechanical and geometrical properties of parts formed by SBMF.

2 Applied Methods and Material

The deep drawing steel DC04 (1.0338) was used throughout the investigation. This mild, cold rolled deep drawing steel is often applied for cold forming procedures because of its good shaping characteristics. The initial hardness of the material is given as (124 ± 7 HV 0.05) [2].

2.1 Orbital Forming

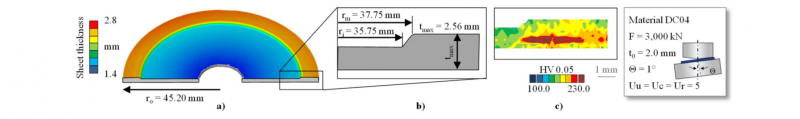

Due to process-specific advantages like short cycle times, low process forces and high accuracy, orbital forming was chosen over comparable production processes of tailored blanks. Since the aim is to locally provide material volume in the areas where it is required, the geometry of the tailored blank has to be adapted individually to the subsequent forming procedure. With regard to the die geometry of the forward extrusion process with cavities for teeth and carrier elements, the design presented in Fig. 3 was selected.

Fig. 3. Characterization of tailored blanks manufactured by orbital forming (a) Showing the resulting sheet thickness distribution, (b) the dimensions of the thickened area and (c) the hardness distribution.

The values of the inner radius r i , the middle radius r m and the outer radius r o were chosen in such a manner, that the zone of increased sheet thickness is large enough to provide additional material for all functional elements, including the carriers. A hydraulic press from the type TZP 400/3 of the company Lasco was used for orbital forming. The process parameters were defined in accordance with previous investigations on orbital forming of DC04 [8]. To obtain a sufficient material thickening in the outer area, a forming force of F = 3,000 kN was selected. In addition, a tilt angle of Θ = 1 ° was applied. Each process phase, the ramp up U u , the holding U c as well as the ramp down U r , consists of five tumbling cycles. During the forming process, the initial sheet thickness of t 0 = 2.0 mm is reduced to a minimum of 1.42 mm in the central component area and increased to a maximum of 2.56 mm in the outer area. The resulting volume dimensions of the thickened area have the potential to enable a complete die filling in the forward extrusion process. Regarding the mechanical properties, average hardness values of (172 ± 29) HV 0.05 are reached. This corresponds to an increase of 48 HV 0.05, compared to the initial hardness of DC04.

2.2 Heat treatment

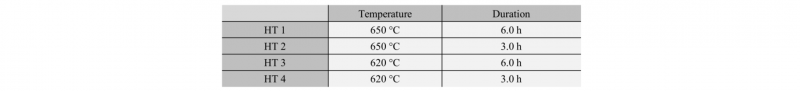

Since work hardening is constantly increasing in multi-stage forming processes, procedures to counteract that effect are required [9]. To reduce the effects of work hardening, introduced into the material by orbital forming, a heat treatment was applied on the semi-finished parts. Due to its potential to restore formability of metallic materials, recrystallization annealing was used. As heat treatment furnace, a TL 1200 of the company Thermal Technology was chosen. For the identification of a suitable recrystallization strategy, four different variants were investigated. The components were inserted after the furnace was completely heated up to the corresponding target temperature. Afterwards, the parts were cooled down at the air. In this study, four variants of heat treatment (HT) were analyzed. Temperature and treatment duration of each variant were set in compliance with further investigations on the heat treatment of processes blanks from DC04 [11] according to Table 1. The long holding times in this fundamental investigation are owing to the activation times of grain reorientation in recrystallization annealing.

Table 1. Variation of temperature and treatment duration of the investigated variants.

2.3 Forward extrusion

All variants of the heat treated tailored blanks are processes in a forward extrusion process to receive the final shape of the component, including functional elements. The tool consists of a die, a punch and a counterholder. Via the punch, the forming force is being applied to the sheet material. To reduce critical tensile stresses in the tool [12], the die is split horizontally. After manual insertion of the tailored blanks into the tool, the downward motion of the ram clamps the sheet between punch and counterholder. The counterholder generates a force of 335 kN and moves downwards together with the punch when this force is exceeded. Teeth and carrier elements are therefore formed in stroke direction. Since involutes are the mainly used tooth geometry used in applications of mechanical engineering [13], they are selected as functional elements in this forward extrusion process. In total, 84 teeth and 21 carriers are spread throughout a rotationally symmetric component with an outer diameter of 90.4 mm.

3 Experimental results

3.1 Microhardness

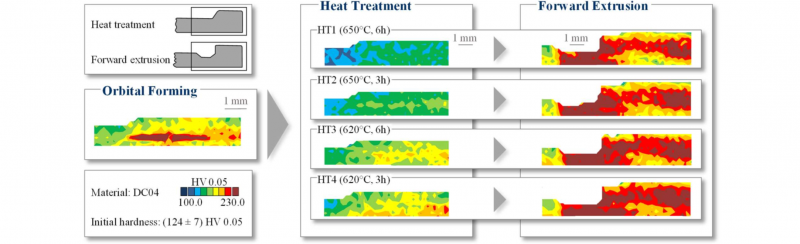

The characterization of the mechanical properties is based on an analysis of the microhardness. Results are presented along the entire process chain. Fig. 4 shows the distribution of microhardness of the blanks from DC04 after the orbital forming and heat treatment, compared to the resulting properties in the following forward extrusion process. Evaluations are confined to the areas of large degrees of deformation. For the orbital formed area, the analysis focuses on the thickened area and in the case of extruded parts, the forming elements as well as the displacement zone are of special interest.

Fig. 4. Distribution of microhardness of blanks manufactured by orbital forming and forward extrusion with intermediate recrystallization treatment.

Overall, all four recrystallization strategies show a reduction of hardness in the thickened area compared to the untreated orbital formed blank. With average values of (140 ± 11) HV 0.05, HT1 reduces the hardness to a greater extent than the three further strategies. Nevertheless, the initial hardness of (124 ± 7) HV 0.05 may not be fully restored. The heat treatment strategies HT2 to HT4 result in a higher hardness of orbital formed tailored blanks. These increase with sinking temperature and holding time. For a heat treatment of three hours at 620 °C, the values are in the range of (167 ± 17) HV0.05. Overall, it can be observed, that all strategies contribute to a softening and thus to an improvement of the material properties for further processing, however they fluctuate widely in a single component. Since recrystallization processes are highly influenced by the degree of deformation that is introduced into the material in the a previous forming process [14], only a locally varying annealing would result in a homogenous softening of the material in order to reach the initial hardness distribution. Furthermore, the influence of the heat treatment strategies on the resulting hardness of the functional elements in forward extrusion are analyzed. Only marginal differences in the average hardness are noticeable. The values vary between (192 ± 24) HV 0.05 for HT1 and (198 ± 25) HV 0.05 for HT4. The reason for this is the high deformation of the material in the area of the functional elements during forward extrusion process. Differences in the hardness after the heat treatment are thereby equalized. As in the application of metal parts with functional elements like teeth, a high hardness is often aimed in order to achieve a long lifetime [15], it can be concluded that the variation of recrystallization parameters only slightly affects the mechanical properties of the finished component.

3.2 Die filling

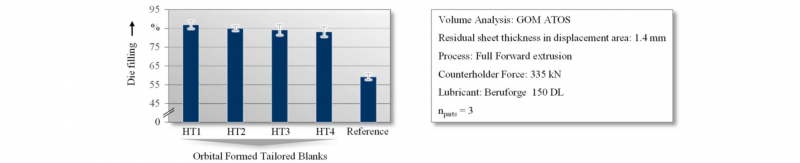

Besides the influence of heat-treated tailored blanks on the mechanical properties, the geometric characteristics are of great importance for further process understanding. In order to verify whether the semi-finished sheet metal parts applied in forward extrusion meet the challenge of cavity underfilling, the die filling is examined comparatively. Fig. 5 shows the percentage of die filling for teeth and carrier elements achieved in forward extrusion. Heat-treated tailored blanks and conventional blanks with an initial sheet thickness of t0 = 2.0 mm as reference are compared. To ensure a suitable comparability of the results, a residual sheet thickness of 1.4 mm in the displacement area was defined as the termination criterion of the forming process.

Fig. 5. Comparison of die filling of different tailored blanks and conventional blanks in a forward extrusion process of SBMF.

The use of conventional blanks with an even sheet thickness distribution results in a die filling of 59.3 %. On the contrary, tailored blanks with a customized sheet thickness distribution lead to a superior die filling. The values are within a range between 86.9 % for HT1 and 83.3 % for HT4. In the variant with the highest die filling, this corresponds to an increase of 46.5 % compared to the reference. The increase is due to the provision of material in the area where it is necessary to form the functional elements. A clear difference of die filling depending on the heat treatment strategies can furthermore not be observed, nevertheless a tendency to an increasing die filling for higher temperatures and longer treatment duration can be seen. Generally, the positive effect of orbital formed tailored blanks on the forming of functional elements in forward extrusion has been proven, with only marginal influence of heat treatment parameters.

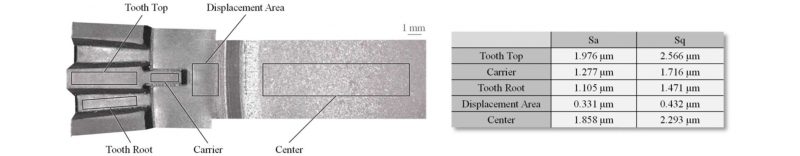

3.3 Surface integrity

In addition to the macroscopic geometry analysis, the microscopic surface integrity was investigated. Five surface areas were defined to obtain comparable results of the surface roughness throughout the whole component. The examined area includes the functional elements, the displacement area and the component center. Since the heat treatment strategy HT1 with an annealing temperature of 650 °C for 6 hours shows the highest die filling, the measurement was performed exemplary for this variant. In Fig. 6 , the evaluated areas with corresponding areal roughness parameters are shown. More specifically, the arithmetical mean height Sa and the root mean square height Sq are presented. High roughness parameters are being measured in the center of the final part as well as on the top surface of the tooth. Lower values are detected in the tooth root and on the top surface of the carrier element. The lowest areal roughness parameter emerges in the displacement area. This can be explained by the varying contact pressures during the forming process in different areas, that influence the smoothing of roughness peaks [16]. Therefore, areas with low occurring contact pressures like the component center show higher roughness parameters than areas with high contact pressures like tooth root and especially the displacement zone.

Fig. 6. Measurement of the areal roughness parameters by InfiniteFocus of Alicona in relevant areas of the component with teeth and carriers produced in forward extrusion

4 Derivation of conclusions

The basic suitability and benefits of tailored blanks for the use in a forward extrusion process of sheet-bulk metal forming has been shown. The focus of the present study was on the influence of recrystallized blanks with a customized sheet thickness distribution on mechanical and geometrical properties of the final part. In this context, four different heat treatment strategies were investigated and compared to a reference process with a conventional sheet blank of even sheet thickness. The microhardness, the die filling and the surface integrity were characterized. Especially the die filling could be highly improved by the application of heat-treated tailored blanks. A minor tendency of increased die filling for tailored blanks treated at high temperatures and longer process times can also be observed. Moreover, the microhardness after the forward extrusion process is only slightly influenced by the chosen variations of recrystallization parameters. Overall, the application of tailored blanks is proven to be beneficial for the manufacturing of parts with integrated functional elements extruded by SBMF. In further studies, the increase of the recrystallization temperature can enable a reduction of the heat treatment time [14]. Orbital forming at high temperatures offers moreover an alternative approach to enhance the economic efficiency of the process and to reduce the production time.

Acknowledgements

This work was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre on sheet-bulk metal forming (TCRC 73, Subproject A2).