1 Introduction

Joining polymer films to produce soft packages is widely used in food processing industries. A package has to fulfill different roles. Depending on the product to be packed, several criteria are required from the package. Complex polymer films are usually used to provide all needed properties. They consist of multilayered films, each layer formed by a different material [1]. Adhesives are used to link the layers with each other, which makes it harder for recycling. For environmental issues, complex films are being replaced with new materials. These new films can be separated into two categories: biopolymers and mono-material films. Biopolymers are made from natural materials. They can be used in some applications to replace traditional complex films. On the other hand, mono-material polymer films are made with different layers of the same polymer type, each layer with a different grade, providing an additional property.

Heat sealing bars is the most used sealing method to fabricate a flexible package. It consists of fixing the films between two bars (more often both being heated), applying a pressure for a certain amount of time until the films are welded [13]. This process is very reliable for mass production, but is limiting in terms of creativity and packaging designs. Each new pouch design requires the manufactory of a specific bar, an operation that can be very expensive, especially if it is for limited production. In addition, new materials (polyethylene mono films for example) are not easily sealed on these types of machines. Process parameters must be adapted, longer dwell times are required, higher temperatures with special coatings on the heated bars.

For all these reasons, Sealester Company is developing a new welding process that will allow the change of pouch design, without any additional cost. This process is capable of sealing new materials, only by changing the process parameters.

A large number of studies were established on the sealing bars process. The effect of each process parameter over the seal quality was determined. Tool temperature, applied pressure and dwell time were the studied parameters. The first tests were made on single-layer films ([5], [6], [7] and [11]) mainly low density polyethylene (LDPE) films, because they are usually used as sealant layers. Furthermore, multilayer films were studied by Planes et al.[8], Marouani [4], and Aghkand et al. [3] Thermal models were established to predict temperature evolution in the polymers, especially at the welding interface between the two films.

In this work, we are comparing the effect of these process parameters on interfacial temperature evolution, knowing that both processes are based on the same principle: heating the sealing layer to create a welded joint. But the heating is performed very differently. In sealing bars, both bars are usually heated, so the heat transfer is symmetric, while in the Sealester process, only the tool side is heated, so the heat transfer is asymmetric. Considering that the film interfacial temperature is the criterion that determines if a sealing is obtained, and since all studies were established on heating bars, the first step to optimize the process was to study the effect of process parameters on the evolution of this temperature with a motionless welding tool.

2 Materials and methods

2.1 Process description

The process is based on the same welding principle as other packaging processes, in particular impulse heat sealing. Sealing is achieved by increasing the temperature at the welding interface, between the films, above a specific temperature, known as “sealing initiation temperature” [9], [10].The difference between Sealester process and traditional sealing machines is that the heat is provided asymmetrically. Usually, both bars that come into contact with the films are heated. In this case, only the tool is heated.

Thus, the interface temperature is no longer a function only of time and tool temperature, but will also depend on the thermal resistance of each of the three thermal layers: the tool, the polymer films and the sealing sheet beneath the films. A less conductive sealing sheet material will provide a higher film interface temperature but will take a longer time to reach thermal equilibrium in the system, whereas a more conductive support will provide a quicker response but a lower interfacial temperature. To minimize heat loss, the machine table is covered with a silicone sheet, but it is maintained at room temperature.

2.2 Films

The films tested in the following experiments are multilayered polymer films usually used for packaging applications. They were bought from Hafliger films SPA. The first film was composed of two layers: 12 μm of polyethylene terephthalate (PET) and 70μm of polyethylene (PE). The second film has the same composition but with a thicker PE layer (120μm). The PE layer is considered to be the sealing layer.

2.3 Thermal analysis

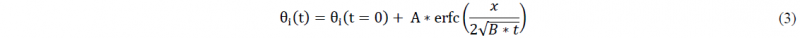

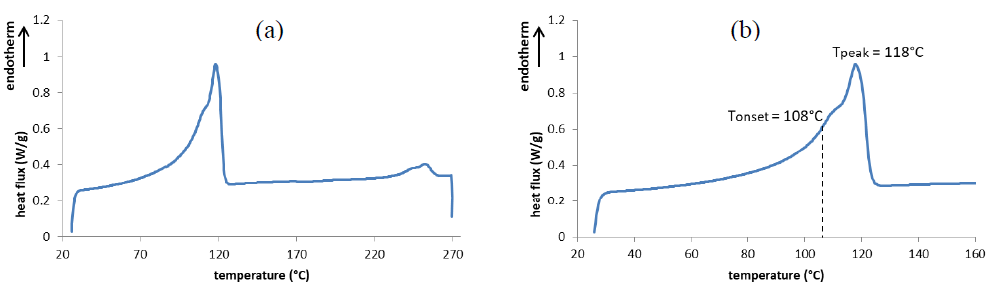

Thermal analysis was performed with a METTLER Differential Scanning Calorimetry (DSC) machine. Melting temperatures of the polymer films were measured. The specimens were subjected to heating and cooling cycles between -20°C and 270°C at a 10°C/min heating rate. It was found that the melting temperatures of PE and PET are respectively 108°C and 240°C (Fig. 1).

Fig. 1: DSC heating scan at 10°C/min, melting endotherm of: (a) PET/PE film; (b) PE layer

Fig. 1: DSC heating scan at 10°C/min, melting endotherm of: (a) PET/PE film; (b) PE layer

Using the modulated DSC method, known as TOPEM, specific heat of the materials was determined. This technique consists of applying a modulated temperature signal in superposition with linear DSC temperature program. This way, quasi-static material properties can be evaluated. The heating rate was 2°C/min. It was found that specific heat of polyethylene increases from 1.78 J/kg°K to 2.75 J/kg°K for a temperature range of -20°C to 230°C. And specific heat of the silicone increases from 1.13 J/kg°K to 1.5 J/kg°K between 25 °C and 250°C.

2.4 Testing method

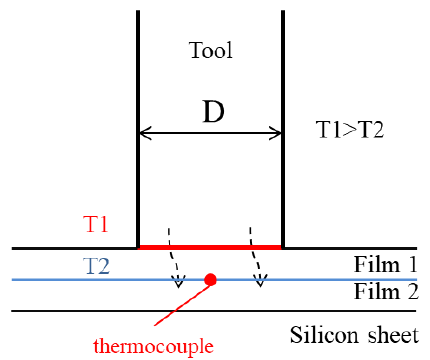

The first step was to determine the effect of process parameters in static tests. Two polymer films were fixed on the machine table with sealing layers in contact at the welding interface. The heated tool was programmed to apply a specific pressure on the films, for a given amount of time. Several values of contact time, pressure and tool temperature were tested. In each case, a thermocouple of 25 micrometres diameter measured the temperature evolution at the welding interface between the films (Fig. 2).

Fig. 2: Schematic of the test method

Fig. 2: Schematic of the test method

3 Results and discussions

3.1 Temperature evolution at the interface

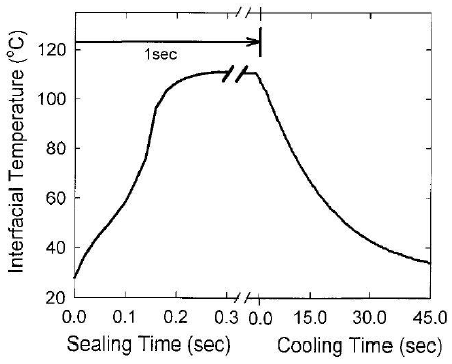

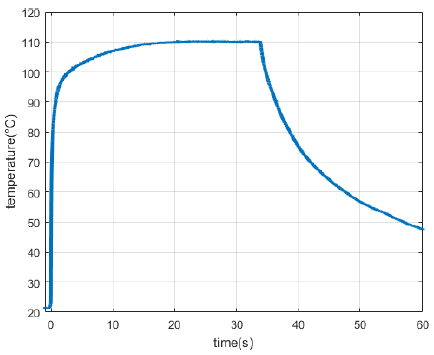

In symmetric heating bars, it was shown that the interfacial temperature evolution has a specific form (Fig. 3 ). An example of the interfacial temperature evolution for asymmetric heating is shown in Fig. 4. As we can see, the aspect of the curve is very similar to the schematic proposed by Mueller et al.[6] for heat bars sealing. The first part of the heating zone is characterized by a temperature increase until it reaches a maximum value. This maximum is maintained constant for higher sealing time.

Fig. 3: Scheatic evolution of interfacial temperature in heat bars sealing [6].

Fig. 3: Scheatic evolution of interfacial temperature in heat bars sealing [6].

Fig. 4: Interfacial temperature evolution in static test for tool temperature = 120°C

Fig. 4: Interfacial temperature evolution in static test for tool temperature = 120°C

Hishinuma [2] proposed a conversion from the heat transfer system for heat sealing to an electric circuit. The interfacial temperature evolution in heating phase could be calculated using the unit step response of first order systems:

In the case of heat sealing, the time constant k depends on the material properties of the polymer films.

But for the Sealester process, this equation cannot be applied: the conditions for the time constant are not respected. In fact, in order to apply the proposed formula, time constant τ must be chosen so that 63% and 95% of the maximum temperature are reached at τ and 3τ respectively. In the case of asymmetric heating such time constant cannot be determined. For example, in the curve of Fig. 4; 95% of maximum temperature is achieved at t=6.89s. If we consider that 3τ = 6.89s, then 63% of maximum temperature (equivalent to 69.3°C) should be reached at 1.67s, which is not the case (at t=1.67s, the interfacial temperature is equal to 97°C). The same applies for other temperature measurements as well.

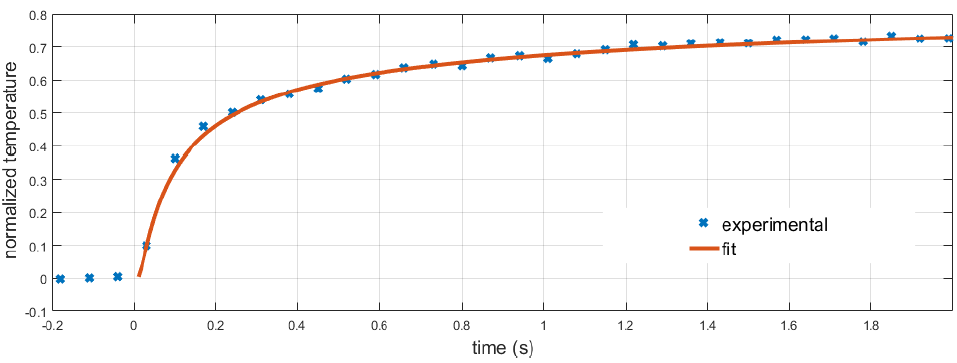

On the other hand, interfacial temperature evolution in the Sealester process tends to follow the form of diffusion heating, calculated using the complementary error function (erfc).

Interfacial temperature is normalized in function of the tool temperature and initial interfacial temperature in each case, following the equation:

with Ti the measured interfacial temperature, and Ttool the measured temperature in the tool.

An equation of the form:

is fitted on the normalized interfacial temperature curve. The result is shown in Fig. 5. The corresponding diffusivity value obtained is 4.36E-08 m/s2.

Fig. 5: Fit between normalized interfacial temperature and erfc equation

Fig. 5: Fit between normalized interfacial temperature and erfc equation

3.2 Effect of tool temperature

Interfacial temperature evolution in function of tool temperature is the first parameter studied in the literature. Researchers have found that higher tool temperature induce higher interfacial temperature for a specific time [3], [11]. In addition, the maximum temperature reached at the interface increases with the tool temperature.

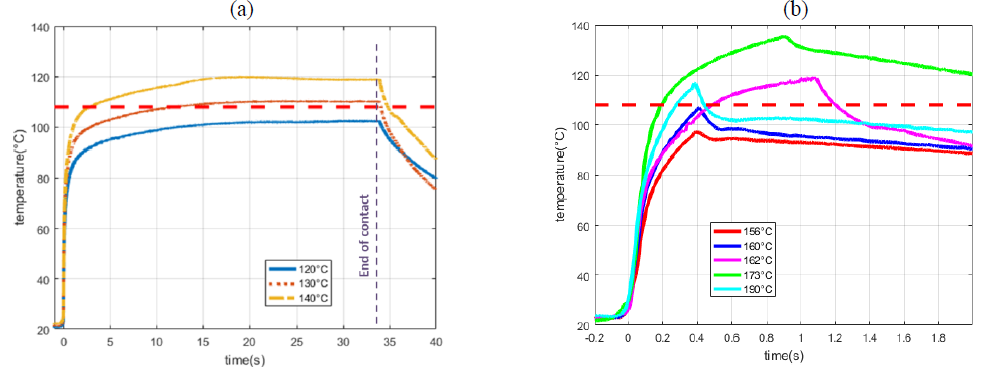

In the following experiments, the pressure was fixed. Several tool temperatures were tested. For temperatures lower than 150°C, the sealing time was equal to 33 seconds, whereas for higher temperatures, the sealing time considered was between 0.4 and 1 second. As can be seen in Fig. 6, each temperature evolution at the interface corresponds to a specific tool temperature. For higher tool temperatures, the interface temperature increases more rapidly and reaches a higher maximum.

Fig. 6: Interfacial temperature evolution in time for different tool temperatures

Fig. 6: Interfacial temperature evolution in time for different tool temperatures

These results are coherent with previous studies, established on heating bars [11]. For tool temperature equal to 120°C, the films are not sealed. For the same sealing time, when tool temperature reaches or exceeds 130°C, a sealed joint is formed (Fig. 6). These values correspond to interfacial temperature reaching 108°C or higher. For higher tool temperatures, the sealing is not established when the interfacial temperature stays below 108°C (curves of 156 and 160°C of tool temperature, Fig. 6). From our experiments, we infer that the seal initiation temperature (SIT) is 108°C. Indeed, DSC tests indicate that the onset temperature of fusion of PE is 108°C. This confirms the theory given by Qureshi et al.[9], as well as Meka and Stehling [11]. They found that, to achieve a welded joint, a seal initiation temperature should be reached at the welding interface. Qureshi defined this temperature to be equal to Tm + 4°C, with Tm melting temperature of PE measured by DSC. Based on these tests, a minimum operating tool temperature can be determined for each material. It consists of the one that maintains interfacial temperature equal to seal initiation temperature whatever the value of the sealing time.

3.3 Effect of sealing time

Mueller et al. [6] studied the effect of sealing time on the melting and interdiffusion of linear low density polyethylene (LLDPE) films. They proved that there is a minimum tool temperature required to generate interdiffusion of polymer chains, thus generating a sealed joint. In addition, SEM images after peeling of the welded joints showed that higher sealing time generates better adhesion between the films, increasing the peel strength of the joint. Meka and Stehling [11] concluded that seal strength is variable with sealing time.

Following the interfacial temperature evolution when the tool is heated at 140°C, in Fig. 6, we see that it takes 15 second to reach its higher point (110°C in this case) which is maintained for the rest of the sealing time. The same profile can be observed for higher tool temperature. Except that in this case, a higher maximum temperature is reached more rapidly. These results show that the sealing time depends on the tool temperature. A minimum time is required in each case, to allow the interface temperature to increase and reach the sealing initiation temperature. This minimum decreases with the increase of tool temperature. In Fig. 6, we see that a tool temperature of 156°C cannot achieve sealing at short time (0.4secondes), while for the same instant; a tool temperature of 190°C elevates the interfacial temperature at 122°C. So we can say that, like in symmetric heating sealing processes, sealing time is an important parameter, but it will always depend on the tool temperature.

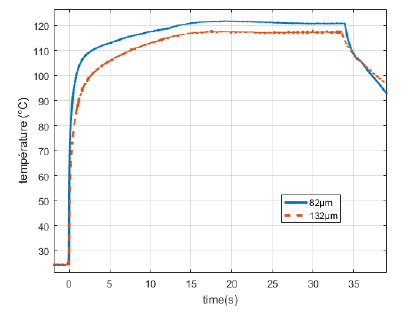

On the other hand, by comparing interfacial temperature evolution in thicker films, we see that for same tool temperature, the welding interface needs more time to reach 108°C and the maximum reached temperature is around 117°C, lower than for thinner film where the interface reaches a maximum of 121°C for the same tool temperature (Fig. 7).

Fig. 7: Interfacial temperature evolution for different film thicknesses

Fig. 7: Interfacial temperature evolution for different film thicknesses

These results show that sealing time also depends on the thickness of the polymer films to be welded.

3.4 Effect of pressure

Pressure is essential in heat sealing because it creates an intimate contact between the films at the sealing interface. Yang and Pitchumani [12] determined the relation between the intimate contact degree and the applied pressure. They concluded that a minimum pressure is required to create a sealed joint. The results obtained by Marouani [4] on aluminum coated polymer complex films revealed a minimal effect of the pressure on the heat seal force, in the studied range of values (between 2.2 bar and 2.55 bar). Meka and Stehling [11] found that higher pressure can cause material flow and deformation around the sealing area, resulting in a distorted, aesthetical and displeasing seal.

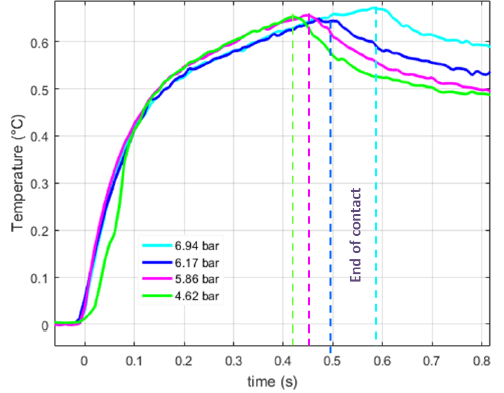

In the case of this work, tool temperature was maintained at 200°C and the sealing time equal to 0.4 seconds. Interfacial temperature was normalized in order to remove tool temperature fluctuations. Fig. 8 shows the evolution of normalized interfacial temperature along time for 4 different values of applied pressure. The normalization was calculated by following eq.(2).

Fig. 8: Interfacial temperature evolution for different pressure values

Fig. 8: Interfacial temperature evolution for different pressure values

We can deduce that for a constant tool temperature, the change of applied pressure between 4.6 bar and 7 bars does not affect the maximum temperature reached at the welding interface. However, we can see that the evolution at low pressure (4.6 bar and 5.9 bar) is different than for higher pressures (6.2 bar and 7 bar). An explanation of this result could be that for higher pressure, the contact between the film and the silicone support is more complete, lowering the thermal resistance between the films and the support. This affects the interfacial temperature evolution that becomes less important because the heat flux is transmitted into the support.

By observing the welded joint, we can see that its deformation is more important with higher pressure: the extremities of the sealed area are more visible. The material is more squeezed under the tool. By applying a peeling effort on the welded joint, the breaking is more likely to occur in the film at the edge of the sealed area for films welded at high pressure.

This result is identical to heat bars sealing: a minimum pressure is required to maintain intimate contact between the sealing layers, but too much pressure might weaken the edges of the seal, causing a break of the polymer film at high effort.

4 Conclusion

In this work, we presented a new sealing process that can be used for packaging applications in food processing industries. It is different than traditional heat sealing processes by the way heat flux is applied. Normally, the heat flux is symmetric; both faces of the films are heating, while in this case the heating is asymmetric. Main process parameters effect on interfacial temperature evolution was studied. It was found that the temperature of the tool has the most important effect. A specific minimum working temperature is required for each type and thickness of polymer film. Sealing time is determined by the linear velocity of the sealing head. Higher tool temperature and thinner polymer films require less sealing time. It was proven that the effect of pressure, in the studied range, was not important. Temperature profile remained the same for different pressure values. Only the shape of the sealed joint is affected, which can lead to deterioration of seal quality.

Studies of weld quality in function of process parameters, as well as seal joints obtained in dynamic tests with the new welding process, where the heating tool moves along specified trajectory with a given linear velocity will be presented in future works.

Acknowledgements

This work was established as part of a thesis, in collaboration with the company SEALESTER and the GEPEA and GeM laboratories.